Isotope low-temperature rectifying device

A low-temperature rectification and isotope technology, which is applied in the field of low-temperature rectification devices, can solve the problems of difficult to satisfy the thermal insulation effect, large amount of thermal insulation materials, poor equipment reliability, etc., and achieves light weight, large equipment weight and low material cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

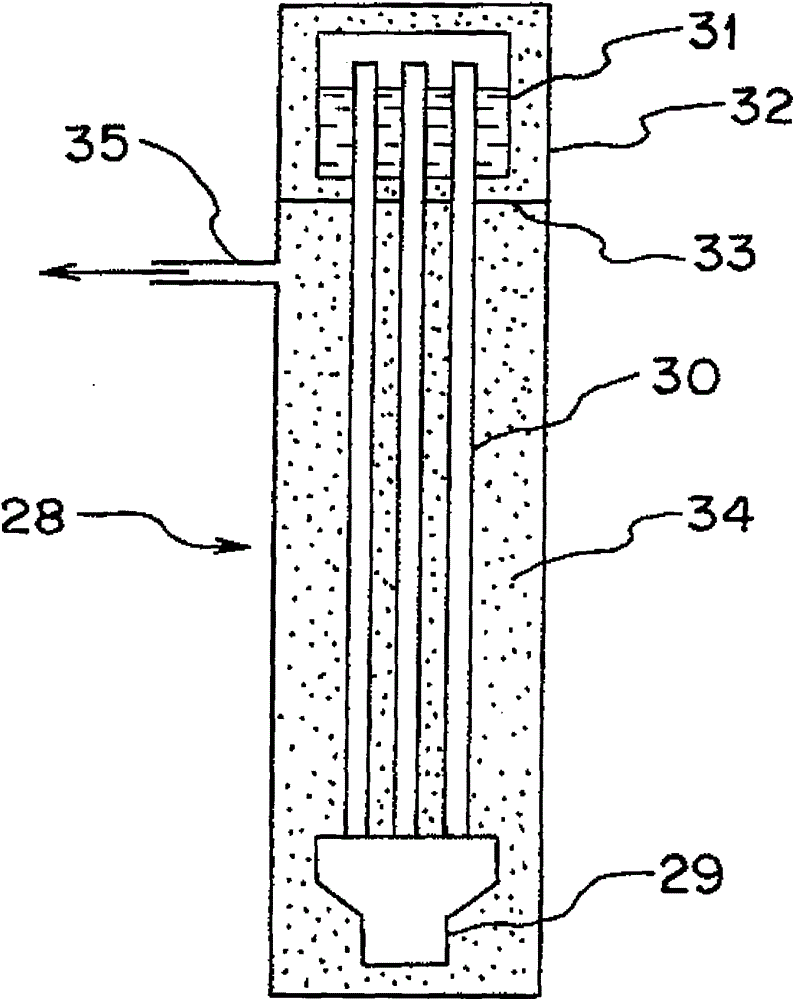

[0033] Cryogenic rectification device for CO cryogenic distillation separation 13 C isotope. The low-temperature rectification device is composed of a condenser 2, a rectification column 6, a reboiler 8, an aluminum foil radiation layer 5, a low-temperature gas cold screen 11, and a vacuum housing 7. A vacuum exhaust port 9 is provided on one side of the vacuum housing 7, see image 3 . The coolant 3 is liquid nitrogen, and the rectifying medium is CO. In the cryogenic rectification tower, the CO vapor-liquid two-phase mass transfer exchange occurs on the surface of the wire mesh corrugated packing in the rectification column 6, containing heavy isotopes 13 The components of C are enriched in the liquid phase and flow to the bottom of the tower; while the components containing light isotopes 12The components of C are enriched in the gas phase and rise to the top of the tower. So through multiple gas-liquid exchanges, in the reboiler 8 13 C is enriched, while the light iso...

Embodiment 2

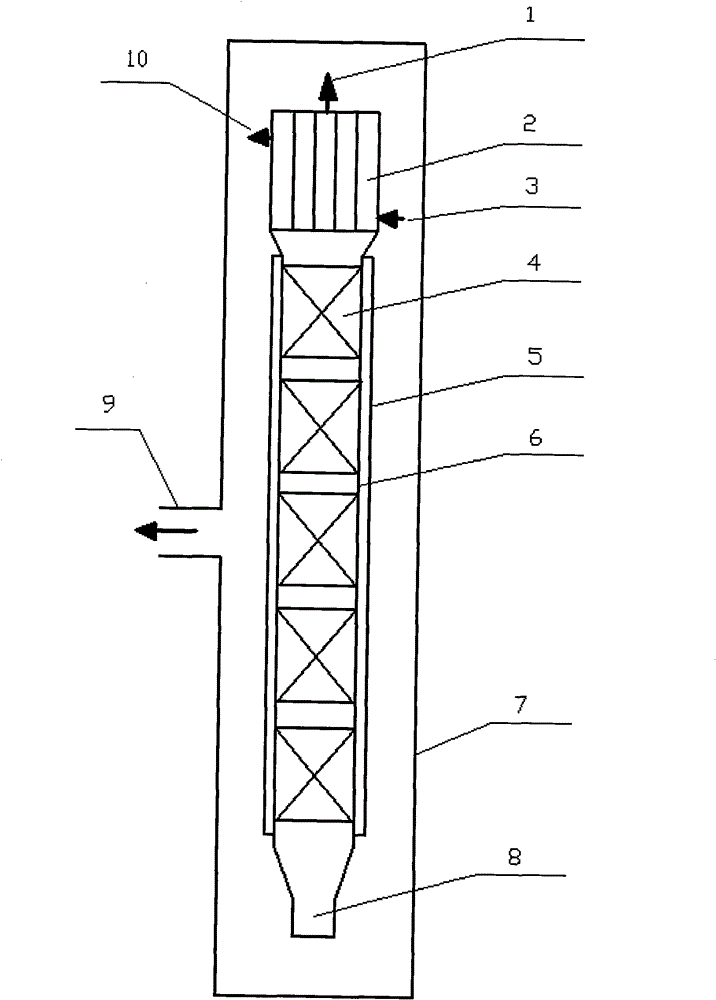

[0035] Cryogenic rectification unit for CH 4 Cryogenic distillation separation 13 C isotope. The cryogenic rectification device is composed of a condenser 2, a rectification column 6, a reboiler 8, an aluminum foil radiation layer 5, and a vacuum shell 7, and a vacuum port 9 is provided on one side of the vacuum shell 7, see figure 2 . The cryogenic coolant 3 is liquid nitrogen, and the rectifying medium is CH 4 . CH in the cryogenic distillation column 4 The gas-liquid two-phase mass transfer and exchange on the surface of the Dixon ring packing 4 in the rectification column 6, containing heavy isotopes 13 The components of C are enriched in the liquid phase and flow to the bottom of the tower; while the components containing light isotopes 12 The components of C are enriched in the gas phase and rise to the top of the tower. So through multiple gas-liquid exchanges, in the reboiler 8 13 C is enriched, while the light isotopes in the overhead condenser 2 12 C is enr...

Embodiment 3

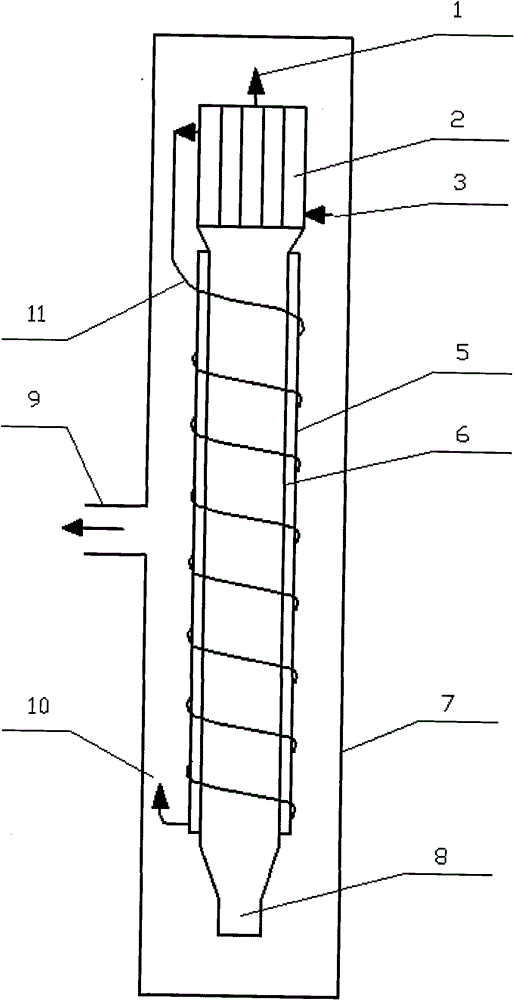

[0037] Cryogenic rectification unit for O 2 Separation of isotopes by cryogenic rectification 18 O. The low-temperature rectification device is composed of a condenser 2, a rectification column 6, a reboiler 8, an aluminum foil radiation layer 5, a low-temperature gas cold screen 11, and a vacuum housing 7. A vacuum exhaust port 9 is provided on one side of the vacuum housing 7, see Figure 4 . The cryogenic coolant 3 is liquid nitrogen, and the rectification medium is high-purity O 2 . In the cryogenic distillation column O 2 Vapor-liquid two-phase triangular or rectangular ring particle packing surface for mass transfer, containing heavy isotopes 18 The components of O are enriched in the liquid phase and flow to the bottom of the tower; while the components containing light isotopes 16 The components of O are enriched in the gas phase and rise to the top of the tower. So through multiple gas-liquid exchanges, in the reboiler 8 18 O is enriched, while the light isoto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com