Fluidized bed granulator

A technology of granulator and fluidized bed, which is applied in the field of continuous fluidized bed spray granulation device, which can solve problems such as nozzle failure, affecting stable granulation, and failure to boil, so as to reduce equipment energy consumption and eliminate Electrostatic and heat exchange sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

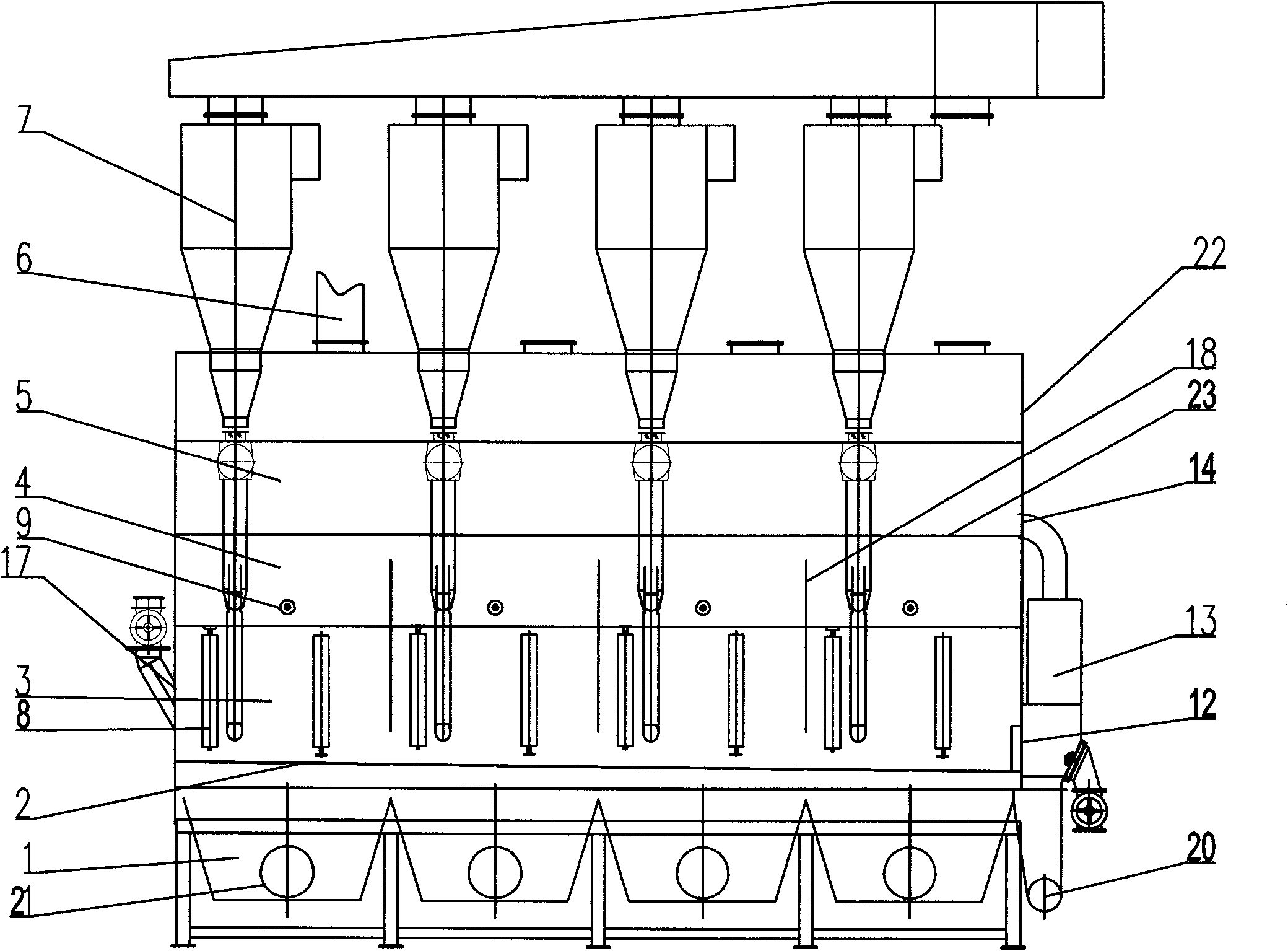

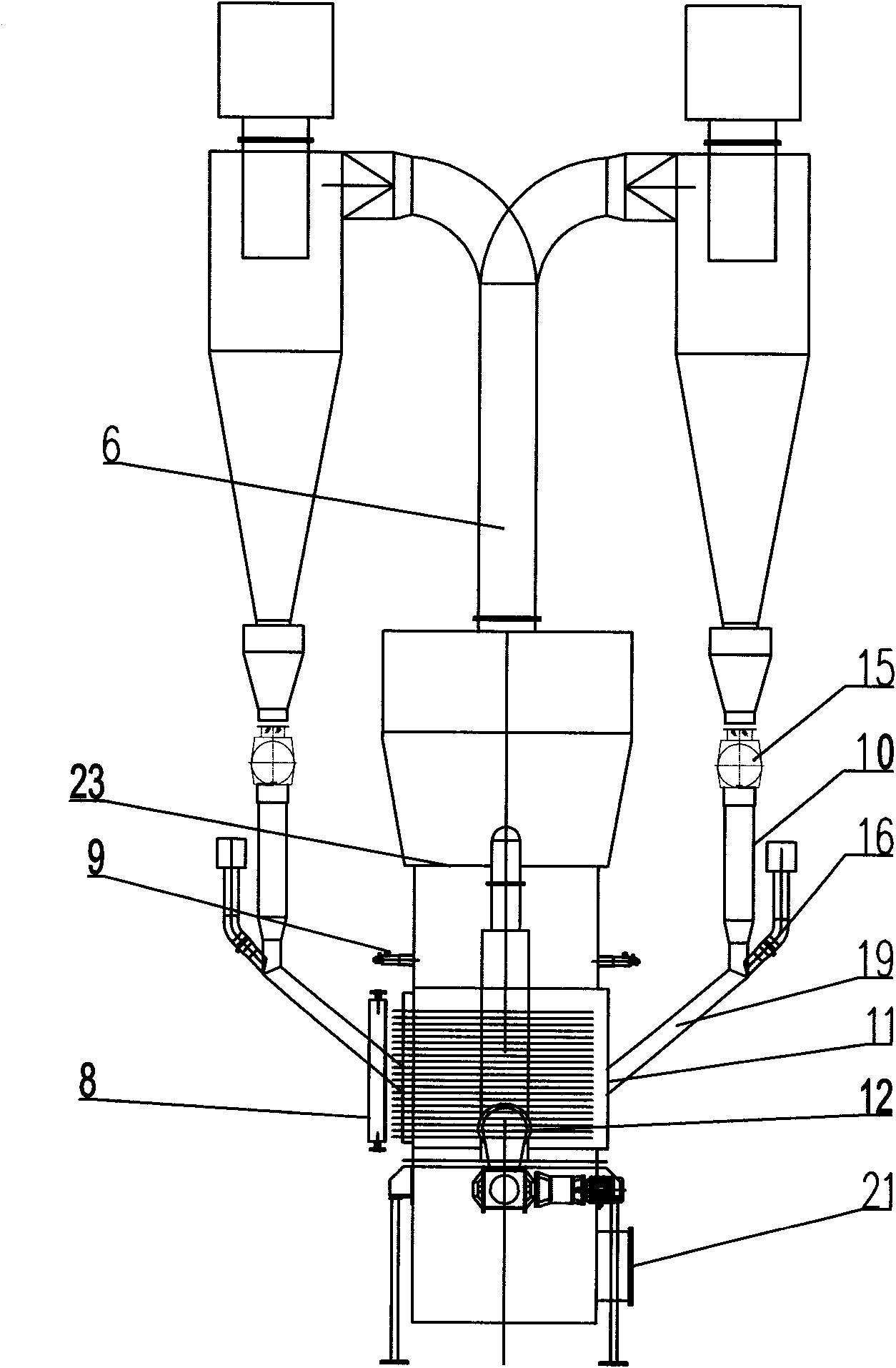

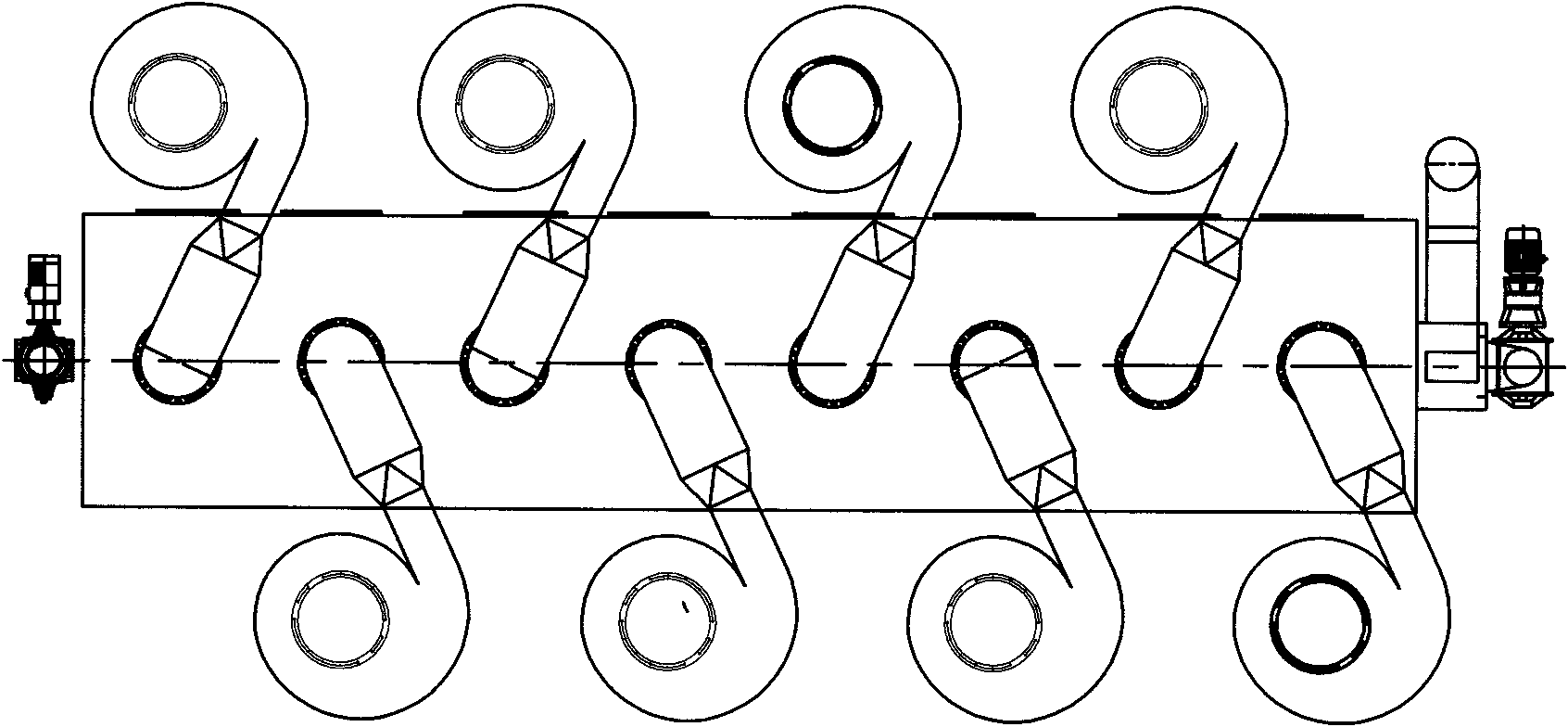

[0041] Such as Figures 1 to 5 As shown: the fluidized bed granulator is equipped with a nozzle 9 and a discharge port 12, and the main body of the fluidized bed is divided into air distribution chamber 1, air distribution screen plate 2, internal heating fluidization chamber 3, and spraying chamber from bottom to top. Fluidization chamber 4, separation chamber 5, a plurality of dust discharge pipes 6 are arranged on the top of the bed body, and a cyclone separator 7 is arranged outside the main body of the fluidized bed. A tube-and-tube heat exchanger 8 is arranged in the inner heating fluidization chamber 3, a nozzle 9 is installed on the side of the spray fluidization chamber 4, a vertical partition 18 is arranged in the fluidization chamber, and a return port 11 is provided The sides of the fluidized chamber 3 are heated internally, and are not higher than the horizontal line where the nearest nozzle 9 is located. The main engine of the fluidized bed communicates with the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap