Method for removing heavy metal Cr from sludge by bioleaching

A technology of biological leaching and heavy metals, applied in the direction of biological sludge treatment, sludge treatment, chemical instruments and methods, etc., can solve the problem of low removal efficiency of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

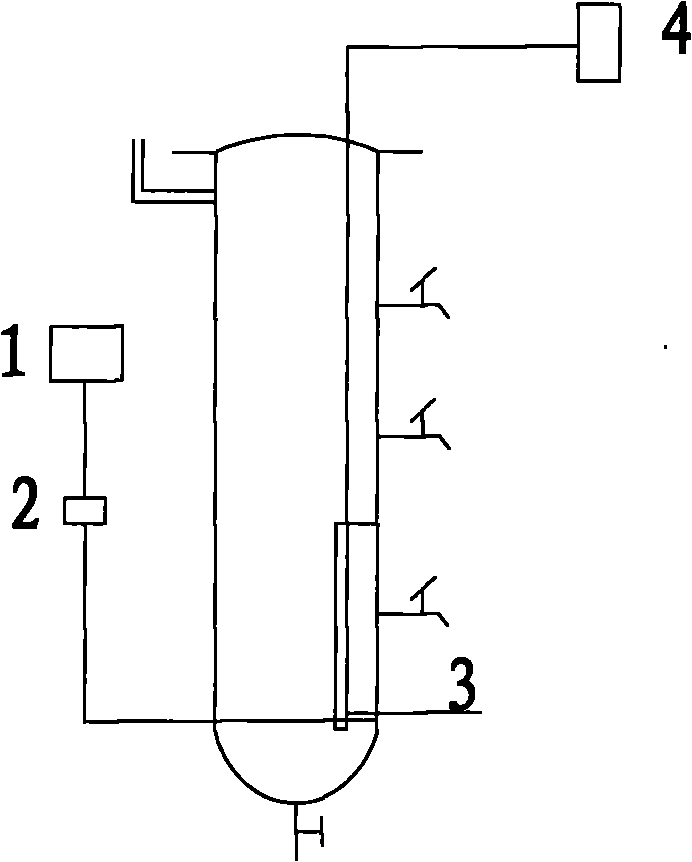

Image

Examples

Embodiment 1

[0021] Take the concentrated sludge in two reactors (one of the reactors is used as a parallel test), and control the sludge concentration at 15g / L-25g / L, and add 3%-6% acclimation to the two reactors at the same time The inoculum, the effective volume of the two reactors is 3L, air aeration is used, and the air velocity is maintained at 0.20-0.35m 3 / h, the initial pH value is controlled at 5.60-5.85, the ratio of substrate concentration to sludge volume (dry weight) is 0.5-0.8, the dissolved oxygen concentration is 7.5-9.0mg / L mg / L, and the temperature is controlled at 25-30°C. Regularly replenish the water consumed by evaporation in the reactor. Samples were taken at intervals, and the samples were centrifuged in a centrifuge for 5-15 minutes to separate the supernatant from the precipitate, and the pH value of the supernatant and the concentration of heavy metals in the leachate were measured. After 8-10 days of bioleaching cycle, the removal rate of heavy metal Cr in the...

Embodiment 2

[0023] The specific method is the same as in Example 1, except that 3% to 6% of the acclimation inoculum is not cast in the process of Example 2, but the sedimentation sludge after the leaching cycle of Example 1 is used as the return sewage of Example 2. Mud, its reflux ratio is 10% to 25%. After 8-10 days of biological leaching cycle, the removal rate of heavy metal Cr in the sludge reaches 40%-52%, which basically meets the sludge reuse standard for agriculture and forestry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com