Flexible micro-surfacing sealing slurry mixture and preparation method thereof

A technology of slurry mixture and micro-surface, which is applied in the field of flexible micro-surface seal layer slurry mixture and its preparation, can solve the problem of limited improvement of micro-surface seal layer crack resistance, cracking and damage of micro-surface seal layer, and difficulty in uniform dispersion and other problems, to achieve excellent low-temperature crack resistance, increase low-temperature crack resistance, and easy dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

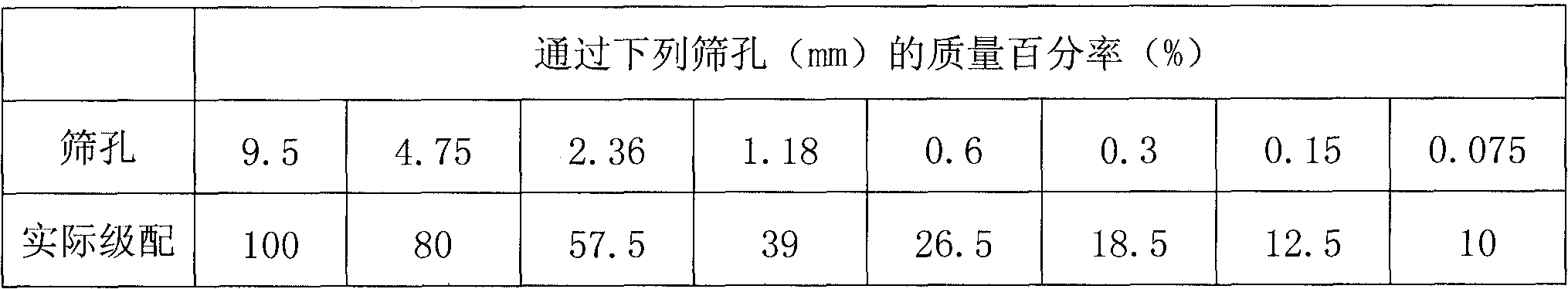

Embodiment 1

[0032] A preparation method of a flexible micro-surface sealing layer slurry mixture, which comprises the steps of:

[0033] 1) Preparation of SBR / FCC oil slurry composite modified emulsified asphalt: 100 parts of base asphalt [penetration at 25°C is 75 (0.1mm)], 5 parts of FCC oil slurry (the mass of aromatic hydrocarbon components in FCC oil slurry content of 60%) and 3 parts of styrene-butadiene rubber (SBR) were mixed at a temperature of 170±5°C, sheared at a high speed for 40 minutes, and then stirred and developed at a temperature of 180±5°C for 2 hours to obtain a composite modified SBR / FCC oil slurry sexual asphalt,

[0034] Pour 2.0 parts of cationic emulsifier (Akzo Nobel E-4875) and 68 parts of water into the container and heat to 65±2°C, stir and adjust the pH value to 2.0 (adjust the pH value of the emulsifier solution with dilute hydrochloric acid=2) , to prepare emulsifier solution;

[0035] Adjust the temperature of the SBR / FCC oil slurry composite modified a...

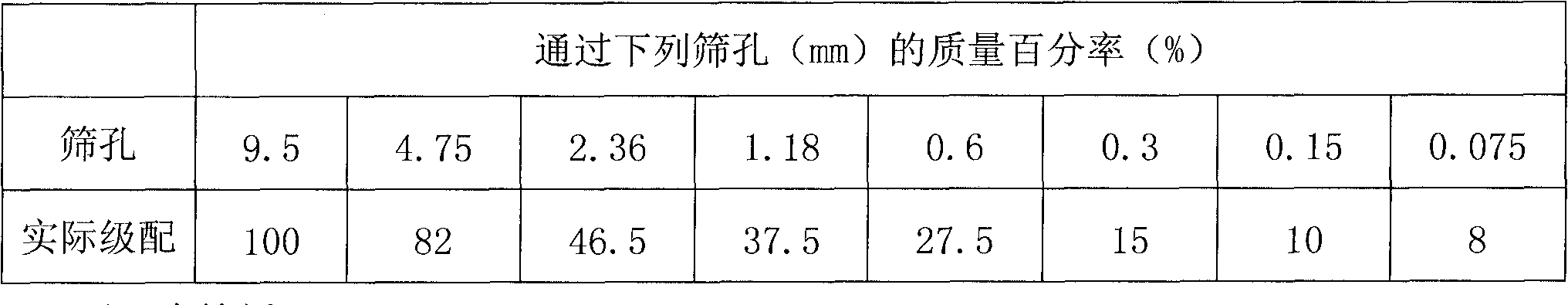

Embodiment 2

[0044] A preparation method of a flexible micro-surface sealing layer slurry mixture, which comprises the steps of:

[0045] 1) Preparation of SBR / FCC oil slurry composite modified emulsified asphalt: 100 parts of base asphalt [penetration at 25°C is 80 (0.1mm)], 10 parts of FCC oil slurry (the mass of aromatic hydrocarbon components in FCC oil slurry content of 60%) and 3.2 parts of styrene-butadiene rubber (SBR) at a temperature of 170±5°C, mixed at a high speed for 40 minutes, and then stirred and developed at a temperature of 180±5°C for 2 hours, that is, the SBR / FCC oil slurry composite modified sexual asphalt,

[0046] Pour 2.2 parts of cationic emulsifier (Akzo Nobel E-4875) and 68 parts of water into the container and heat to 65±2°C, stir and adjust the pH value to 2.0 (adjust the pH value of the emulsifier solution with dilute hydrochloric acid=2) , to prepare emulsifier solution;

[0047] Adjust the temperature of the SBR / FCC oil slurry composite modified asphalt t...

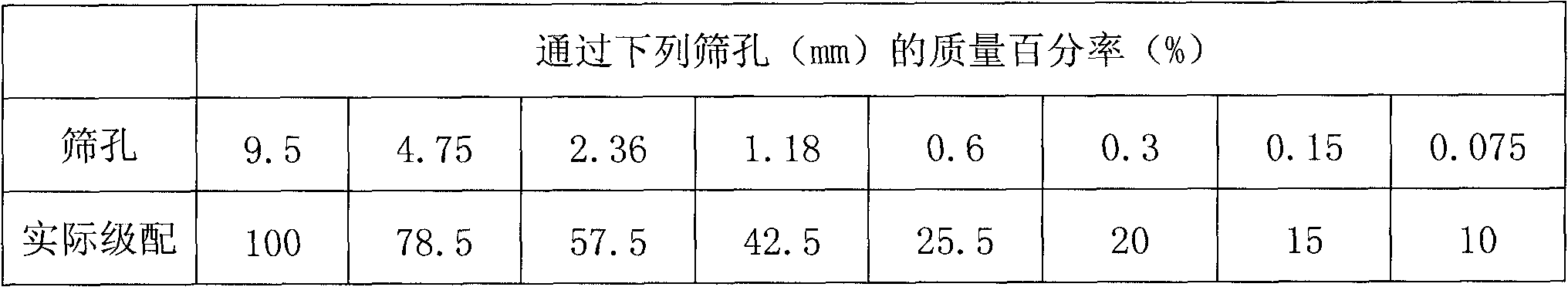

Embodiment 3

[0056] A preparation method of a flexible micro-surface sealing layer slurry mixture, which comprises the steps of:

[0057] 1) Preparation of SBR / FCC oil slurry composite modified emulsified asphalt: 100 parts of base asphalt [penetration of 90 (0.1mm) at 25°C], 12 parts of FCC oil slurry (the mass of aromatic hydrocarbon components in FCC oil slurry content of 58%) and 3.5 parts of styrene-butadiene rubber (SBR) were mixed at a temperature of 170±5°C, sheared at a high speed for 40 minutes, and then stirred and developed at a temperature of 180±5°C for 2 hours to obtain a composite modified SBR / FCC oil slurry sexual asphalt,

[0058] Pour 1.8 parts of cationic emulsifier (Akzo Nobel E-4875) and 70 parts of water into the container and heat to 65±2°C, stir and adjust the pH value to 2.0 (adjust the pH value of the emulsifier solution with dilute hydrochloric acid=2) , to prepare emulsifier solution;

[0059] Adjust the temperature of the SBR / FCC oil slurry composite modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extensibility | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Low temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com