High-performance liquid epoxy resin composition for packaging LEDs

A technology of liquid epoxy resin and LED packaging, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of high viscosity, uninspected light transmittance, unsuitable LED packaging, etc., and achieve low viscosity and high heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

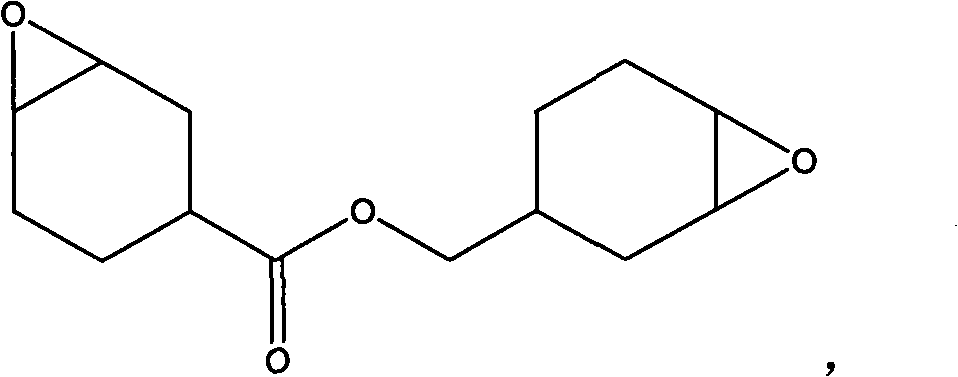

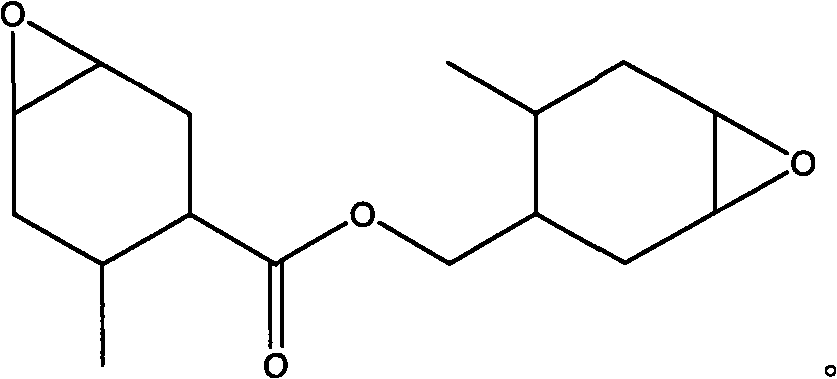

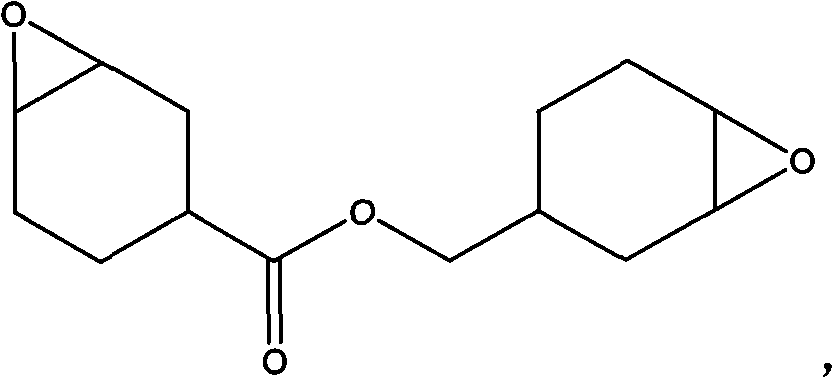

[0036] Preparation example 1: install mechanical stirrer and addition funnel in 1000ml three-neck round bottom flask, add 15 parts by weight of 3,4-epoxycyclohexyl methyl ester of 3,4-epoxyhexanecarboxylate, 85 parts by weight of bis Phenol A type liquid epoxy resin, 0.05 parts by weight of blue color paste, 0.5 parts by weight of defoamer, stirred at 40°C to obtain homogeneous transparent liquid A glue. Install a mechanical stirrer and an addition funnel in a 1000ml three-necked round-bottomed flask, add 20.5 parts by weight of methyl hexahydrophthalic anhydride, 78 parts by weight of hexahydrophthalic anhydride, 0.5 parts by weight of tetrabutylammonium bromide, 0.5 parts by weight of 1 , 4-butanediol, 0.5 parts by weight of an antioxidant, and stirred at 40°C to obtain a homogeneous transparent liquid B glue. Glue A and glue B were stirred at room temperature at high speed for 30 minutes to obtain a uniformly dispersed liquid epoxy resin encapsulation compound.

[0037] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com