Inorganic adhesive for ZnO voltage sensitive ceramic

A technology of inorganic adhesives and pressure-sensitive ceramics, applied in the direction of inorganic adhesives, adhesives, etc., can solve problems affecting the electrical properties of ZnO pressure-sensitive ceramics, improve flow capacity and aging characteristics, reduce process links, and withstand The effect of improving the high-current surge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

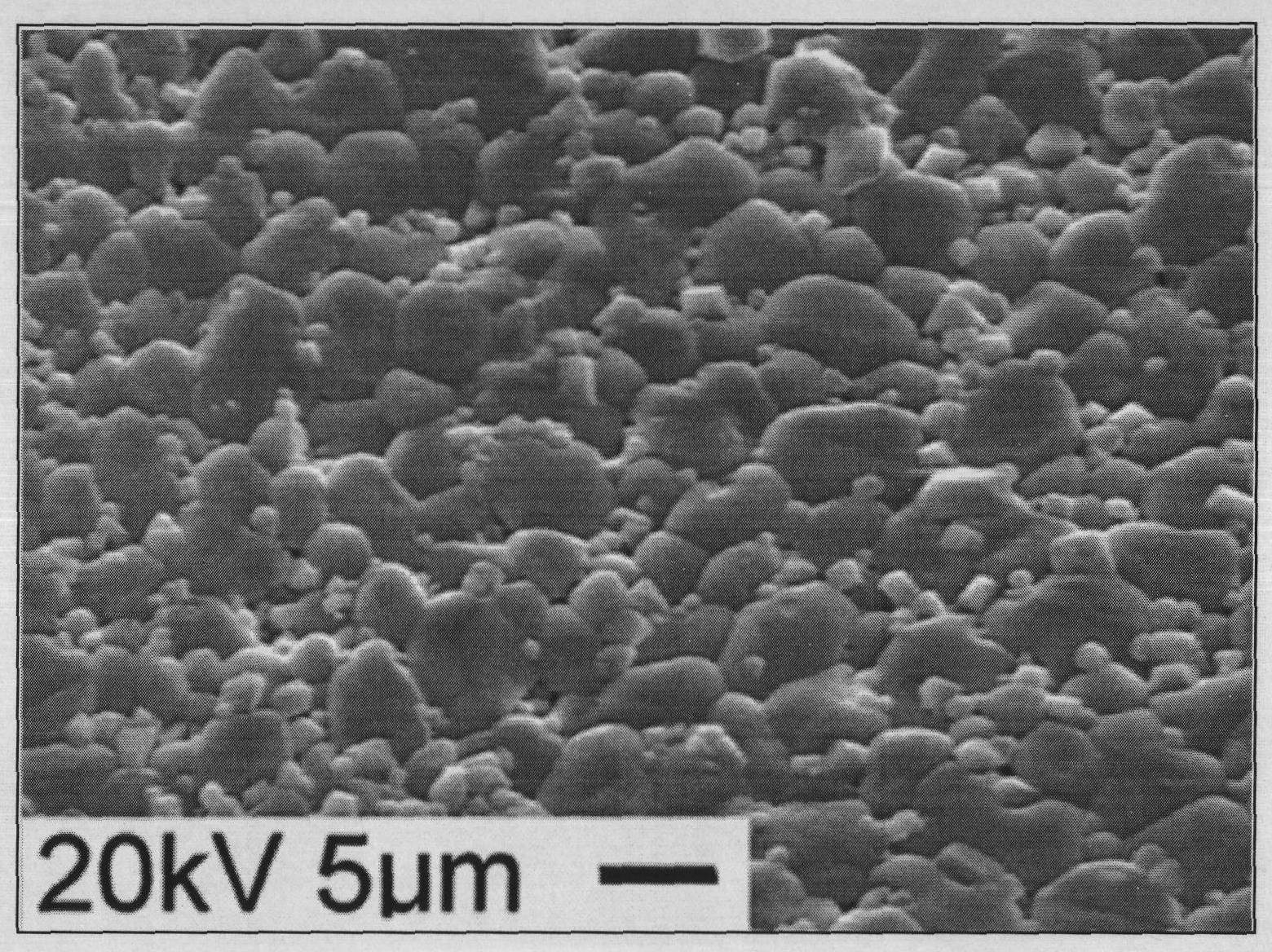

[0021] Raw materials: commercially available magnesium aluminum silicate, aluminum nitrate, silver nitrate, and deionized water are used. According to aluminum magnesium silicate: aluminum nitrate: silver nitrate: deionized water = 1: 0.044: 0.08: 5 (mass ratio) weighing and mixing to prepare the inorganic binder. Then the composition weight ratio is 97%ZnO+1.5%Sb 2 o 3 +1.5% Bi 2 o 3 In the ZnO pressure-sensitive ceramic raw material powder, add the inorganic binder for ZnO pressure-sensitive ceramics prepared above, and based on the total weight of the ZnO pressure-sensitive ceramic raw material powder, the weight percentage of the added inorganic binder is 15 wt%. A resistor sheet with a diameter of 25mm and a thickness of 22mm was prepared by granulation and dry pressing, and a pressure-sensitive ceramic was obtained after sintering at 1150°C for 2 hours. For SEM photos of sintered samples, see figure 1 , it can be seen that it has good compactness.

Embodiment 2

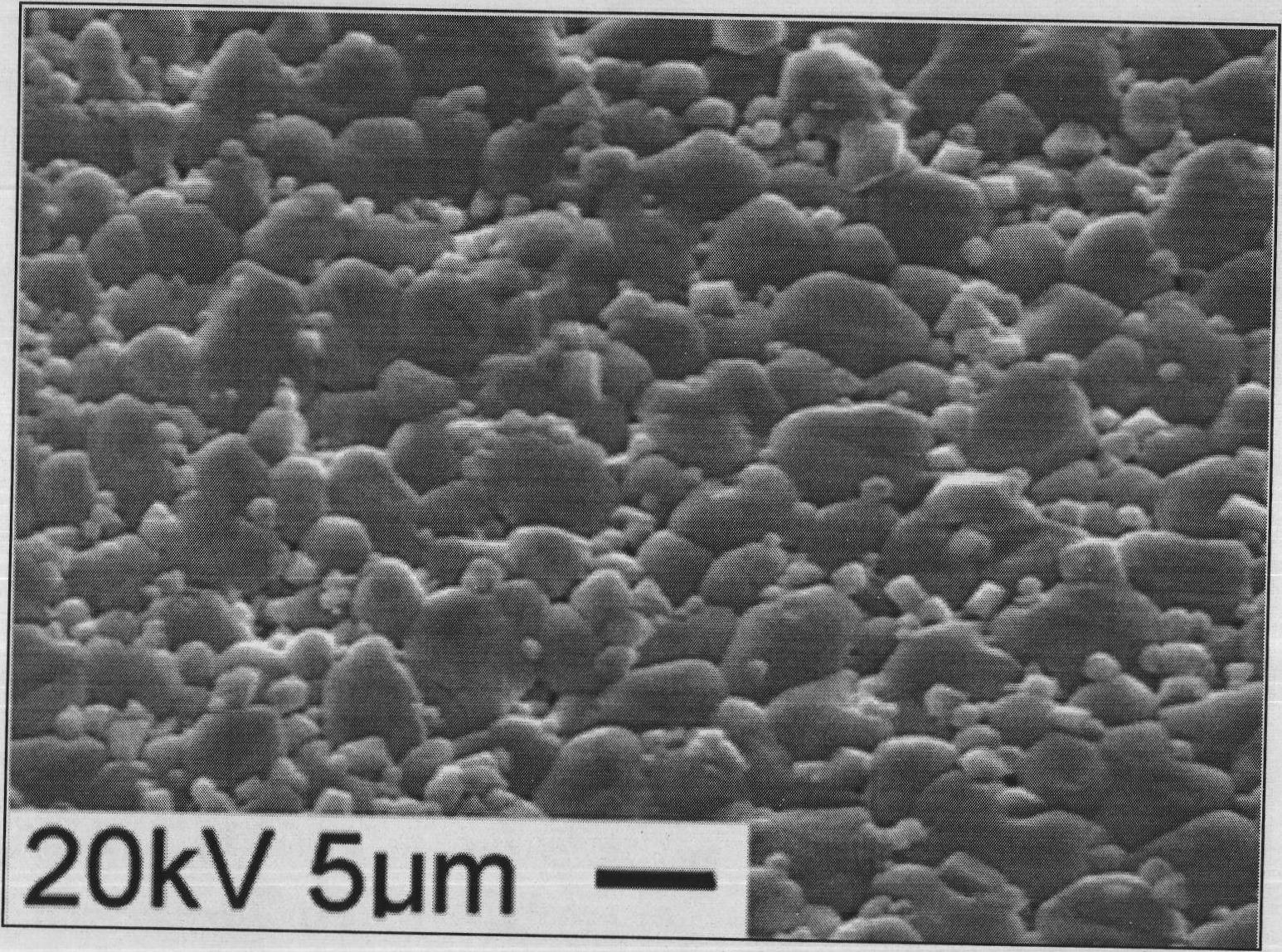

[0023] Raw materials: commercially available magnesium aluminum silicate, aluminum nitrate, silver nitrate, and deionized water are used. According to aluminum magnesium silicate: aluminum nitrate: silver nitrate: deionized water = 1: 0.01: 0.3: 25 (mass ratio) weighing and mixing to prepare the inorganic binder. Then the composition weight ratio is 98%ZnO+1.5%Sb 2 o 3 +0.5% Bi 2 o 3 In the ZnO pressure-sensitive ceramic raw material powder, add the inorganic binder for ZnO pressure-sensitive ceramics prepared above, and based on the total weight of the ZnO pressure-sensitive ceramic raw material powder, the weight percentage of the added inorganic binder is 5wt%. A resistor sheet with a diameter of 25mm and a thickness of 22mm was prepared by granulation and dry pressing, and a pressure-sensitive ceramic was obtained after sintering at 1100°C for 1 hour.

Embodiment 3

[0025] Raw materials: commercially available magnesium aluminum silicate, aluminum nitrate, silver nitrate, and deionized water are used. According to aluminum magnesium silicate: aluminum nitrate: silver nitrate: deionized water = 1: 0.4: 0.02: 20 (mass ratio) weighing and mixing to prepare the inorganic binder. Then the composition weight ratio is 98%ZnO+0.5%Sb 2 o 3 +1.5% Bi 2 o 3 In the ZnO pressure-sensitive ceramic raw material powder, add the inorganic binder for ZnO pressure-sensitive ceramics prepared above, and based on the total weight of the ZnO pressure-sensitive ceramic raw material powder, the weight percentage of the added inorganic binder is 10 wt%. A resistor sheet with a diameter of 25mm and a thickness of 22mm was prepared by granulation and dry pressing, and a pressure-sensitive ceramic was obtained after sintering at 1200°C for 4 hours.

[0026] Refer to Table 1 for the comparative data of the sintered performance of the sintered resistor chips with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com