Double-magnesium chloride pipe reactor for production of sponge titanium and production method of sponge titanium

A production method and technology of magnesium dichloride, which are applied in the field of magnesium dichloride tubes for sponge titanium production, can solve the problems of prolonged production cycle of a single furnace, failure to achieve reduction, integration of distillation and production, waste of energy, etc., so as to shorten the working time of employees. The effect of lengthening and shortening the production cycle of a single furnace and saving the consumption of argon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

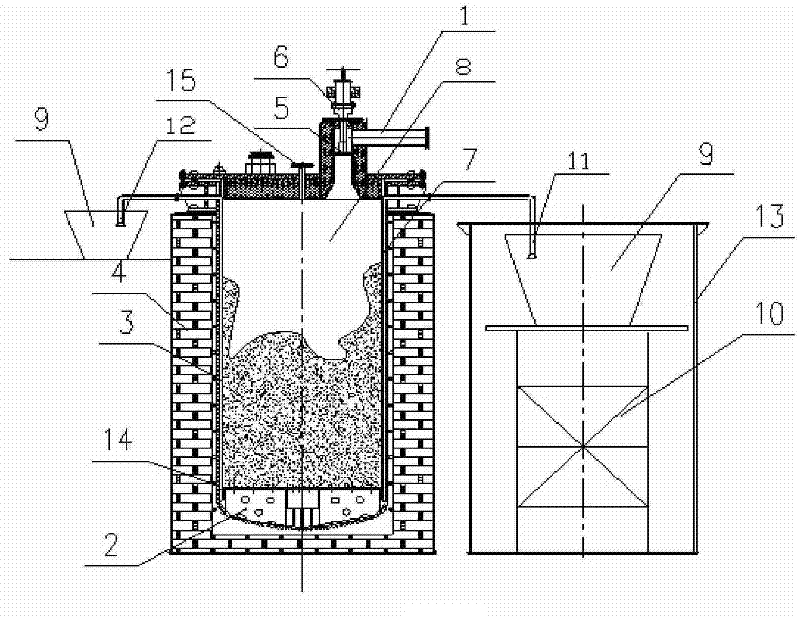

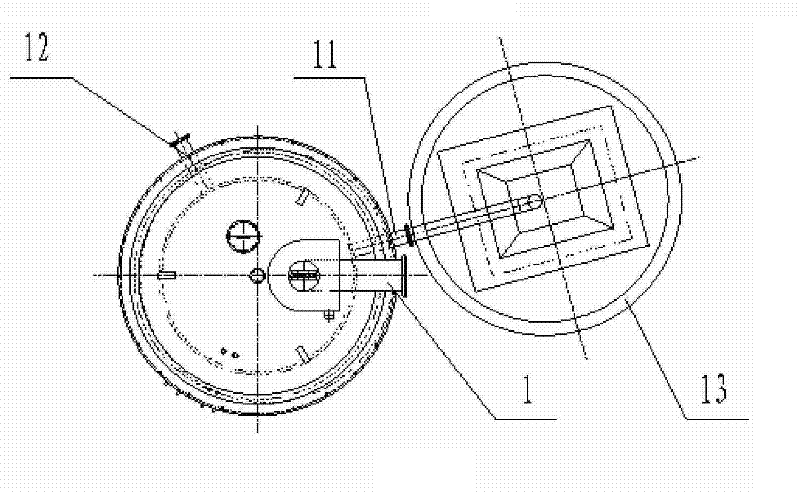

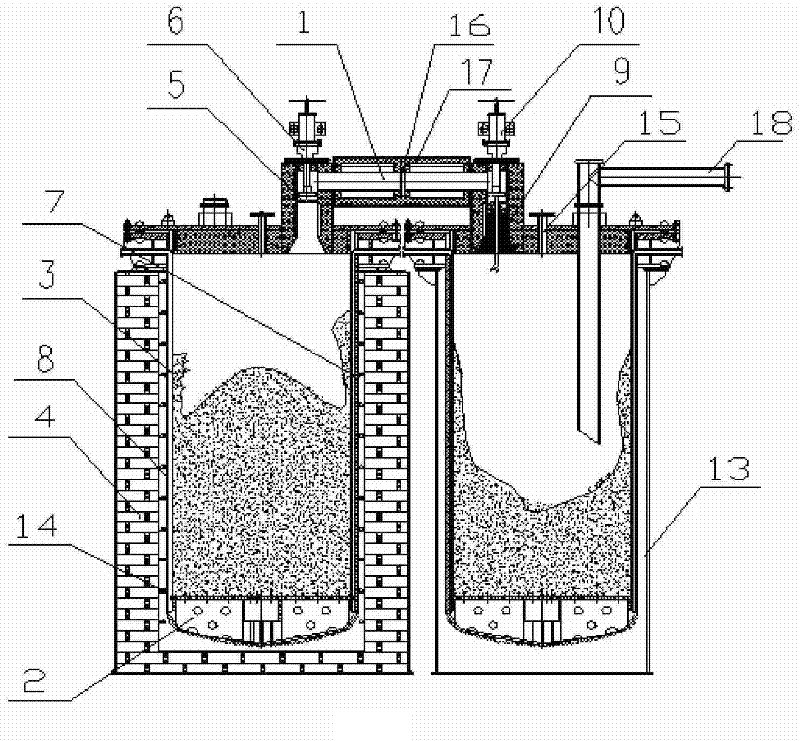

[0050] Example 1 The double magnesium chloride tube reactor of the present invention

[0051] The structure of the double magnesium chloride tube reactor of the present invention is as follows figure 1 , 2 As shown, the double magnesium chloride tube reactor of the present invention includes a tank body 8, the top of the tank body 8 is provided with a feeding port 15, a high temperature valve seat 5 and a high temperature valve 6, and the reactor channel port 1 is connected with the tank body 1 through the high temperature valve 6 , the tank body 8 is respectively connected with one end of the magnesium chloride main discharge pipeline 7 and the magnesium chloride auxiliary discharge pipeline 3, the other end of the magnesium chloride main discharge pipeline 7 is connected with the main magnesium chloride pipe 11, and the other end of the magnesium chloride auxiliary discharge pipeline 3 is connected with the auxiliary magnesium chloride pipe 12.

Embodiment 2

[0052] Example 2 Production of titanium sponge by the method of the present invention

[0053] The double magnesium chloride tube hot-end reactor with a furnace output of 6 tons of titanium sponge is used for reduction production. After the heating furnace is placed in the hot-end reactor, a vacuum tight leak detection test is performed under the cold state of the reactor. The test is qualified for reduction production. 9000kg of magnesium was charged in the double magnesium chloride tube hot end reactor in advance, heated to 700~850℃ in a heating furnace, after 15~24 times of adding titanium tetrachloride and magnesium to react, each time adding 1000~1600kg of titanium tetrachloride , obtain solid titanium and liquid magnesium chloride, the liquid magnesium chloride is discharged from the main discharge pipeline of the reactor, then put the ladle containing liquid magnesium chloride into the nearby magnesium chloride transportation channel and transport it out, carry out elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com