Detection device and method of weft breakage of double-axis warp knitting machine

A yarn breakage detection, biaxial technology, applied in textiles, papermaking, knitting, etc., can solve the problems of high cost, low reliability, easy accumulation of dust on the lens of the lens receiver, etc., to achieve high accuracy and reliability. High, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

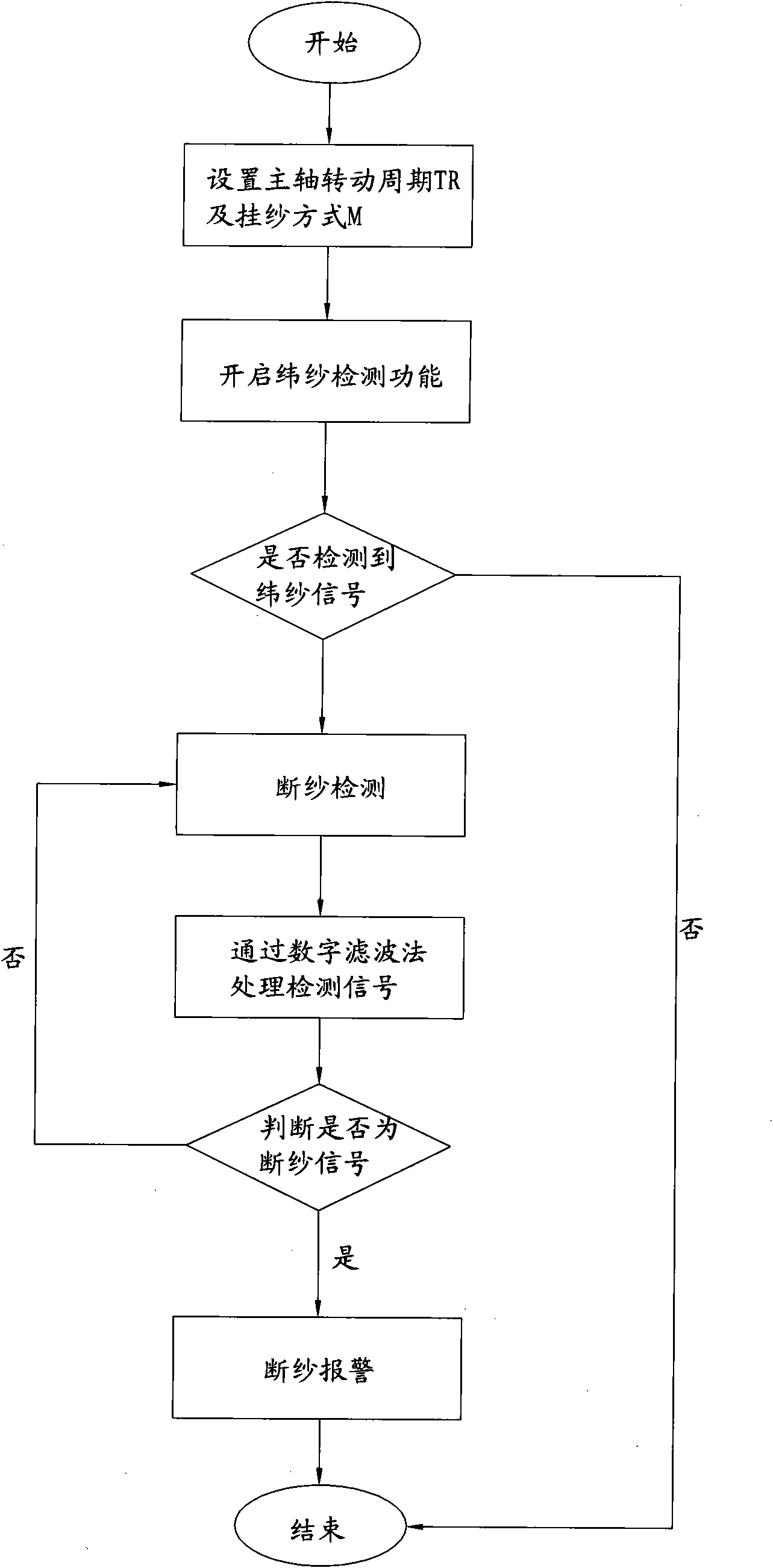

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

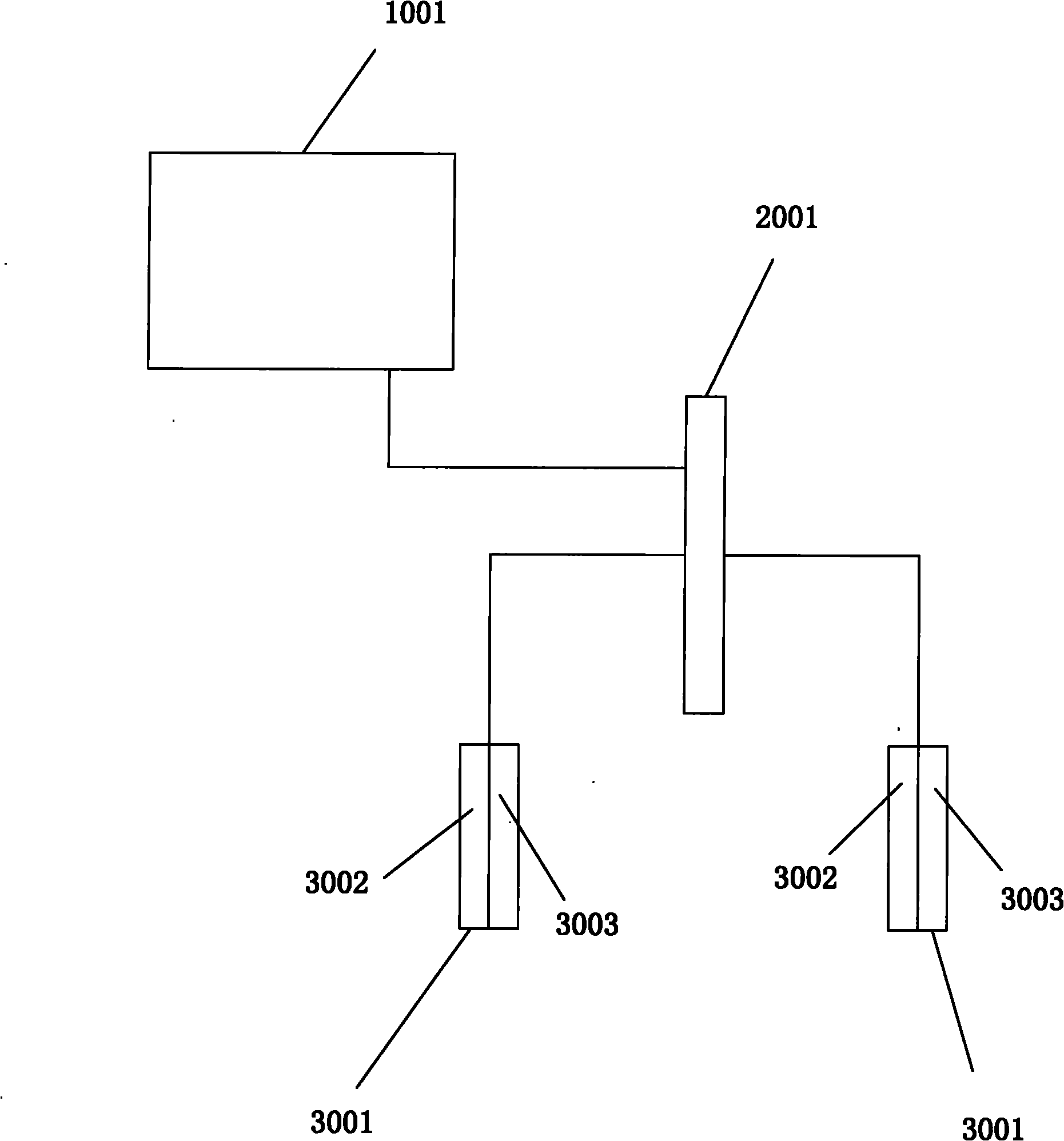

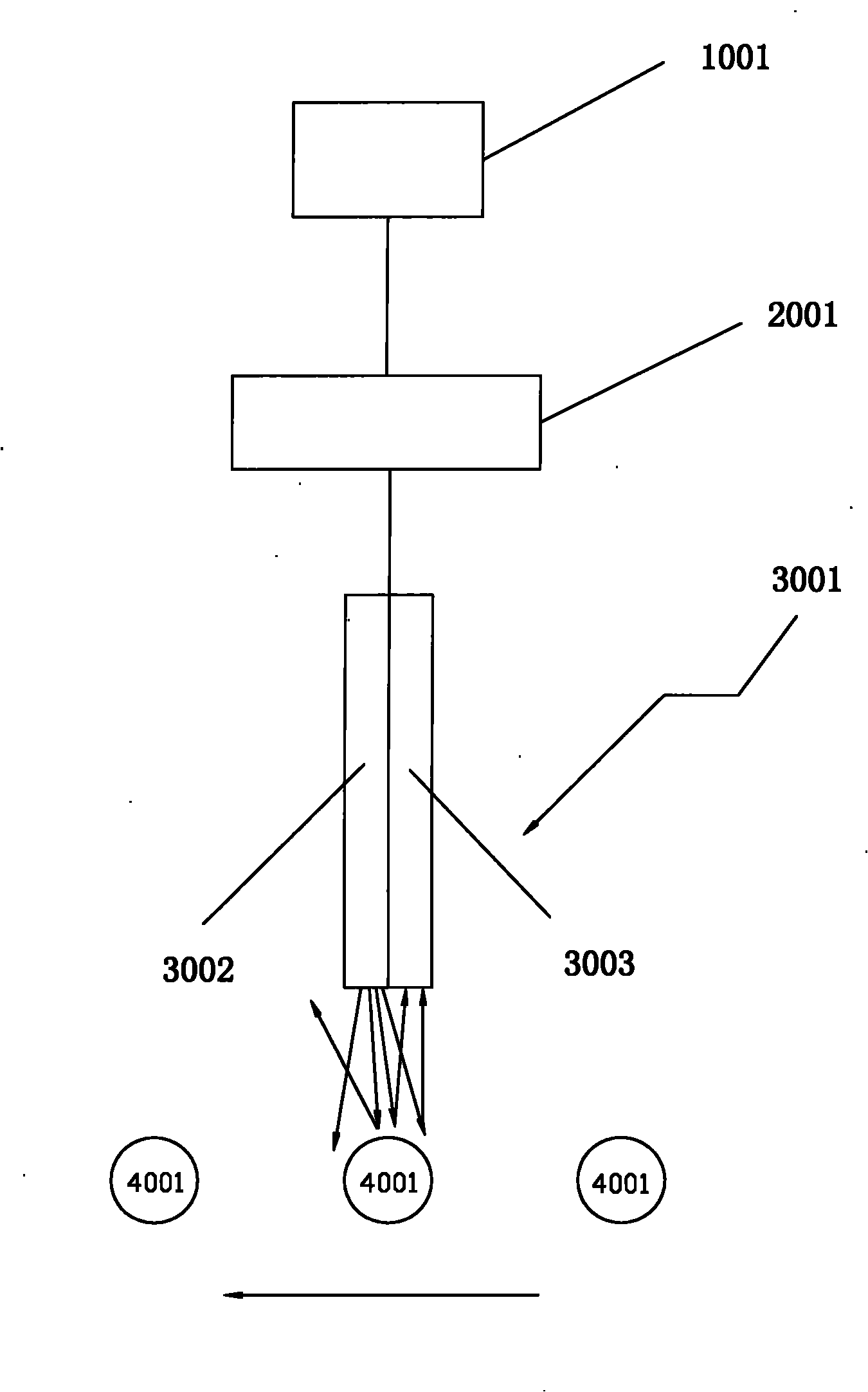

[0025] like figure 1 , 2 As shown, a yarn break detection device for weft yarn of a biaxial warp knitting machine includes a programmable computer controller 1001 and an input / output module 2001, and the programmable computer controller 1001 is communicatively connected with the input / output module 2001, and also It includes a diffuse reflection photoelectric sensor 3001, and the diffuse reflection photoelectric sensor 3001 includes an infrared emitting module 3002 and an infrared receiving module 3003, and the infrared emitting module 3002 and the infrared receiving module 3003 are respectively connected to the input / output module 2001 for communication.

[0026] The preferred diffuse reflection photoelectric sensor of the present invention is the product produced by Kerui Company, the model is 1040-300-506, and this model includes an infra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com