Drainage consolidation method without keeping drainage channel after work of soft soil foundation

A drainage channel, drainage consolidation technology, applied in soil protection, infrastructure engineering, construction and other directions, can solve the problems of upper foundation and structure damage, high maintenance costs, reducing the design life of buildings and municipal pipeline pavements, etc. Achieve the effect of increasing the effective reinforcement depth, reducing post-construction settlement and speeding up the consolidation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

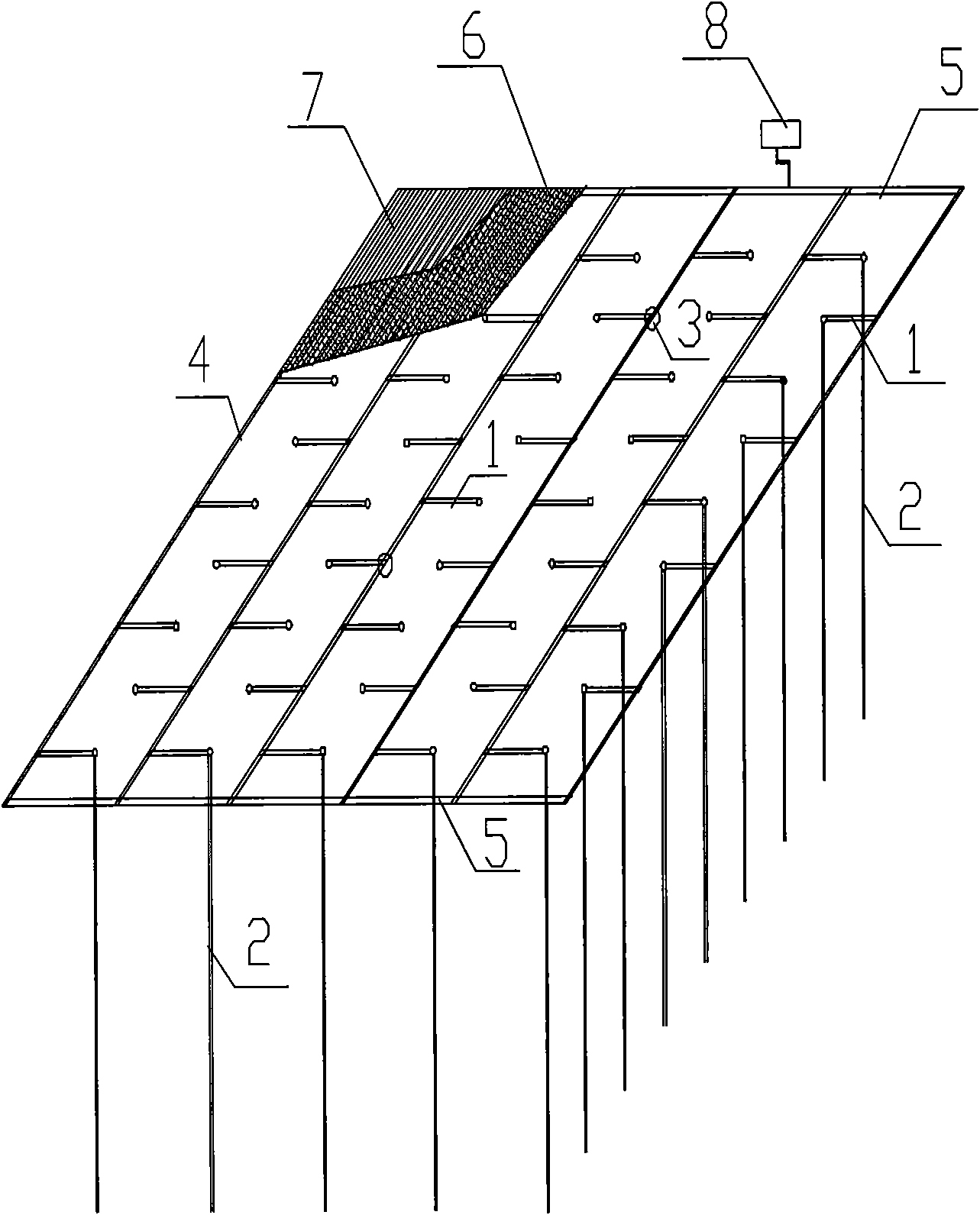

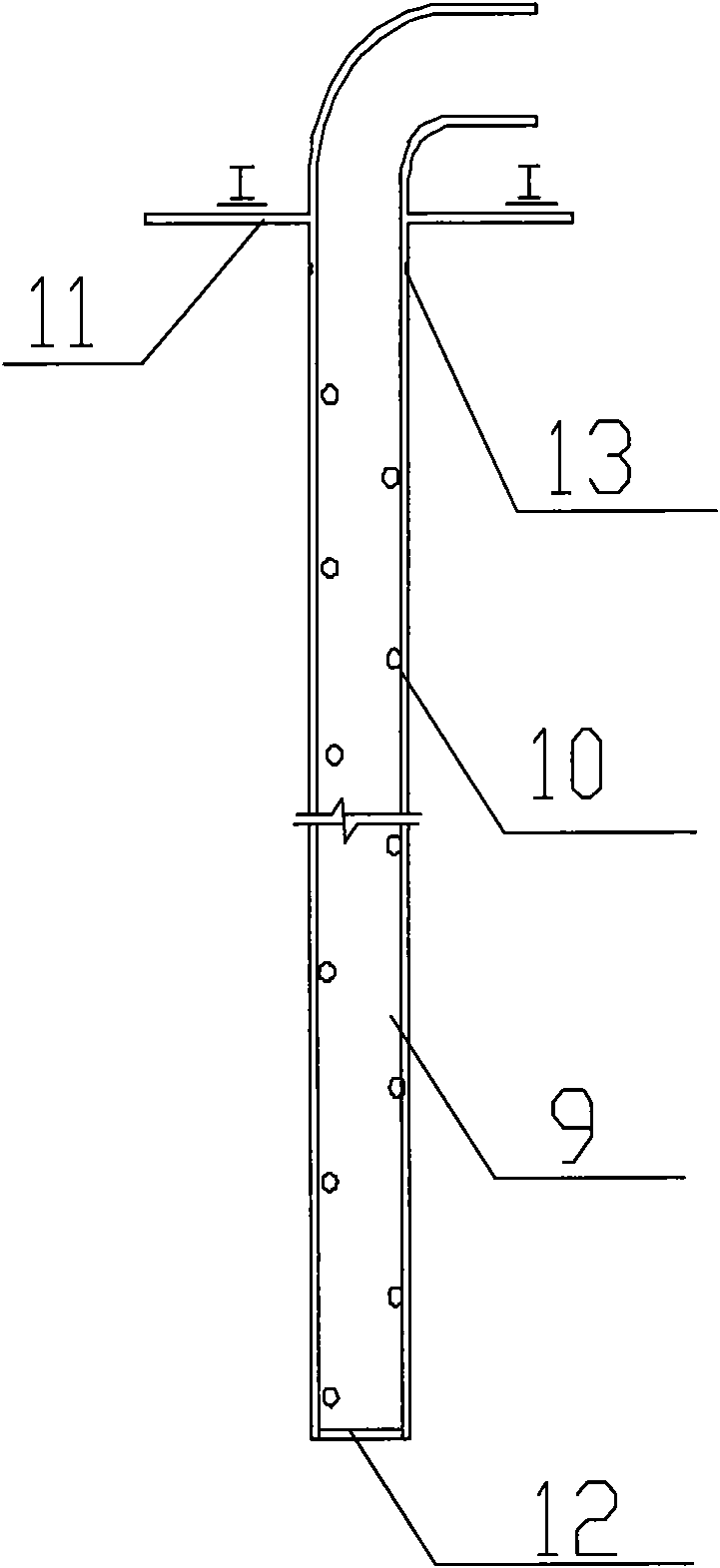

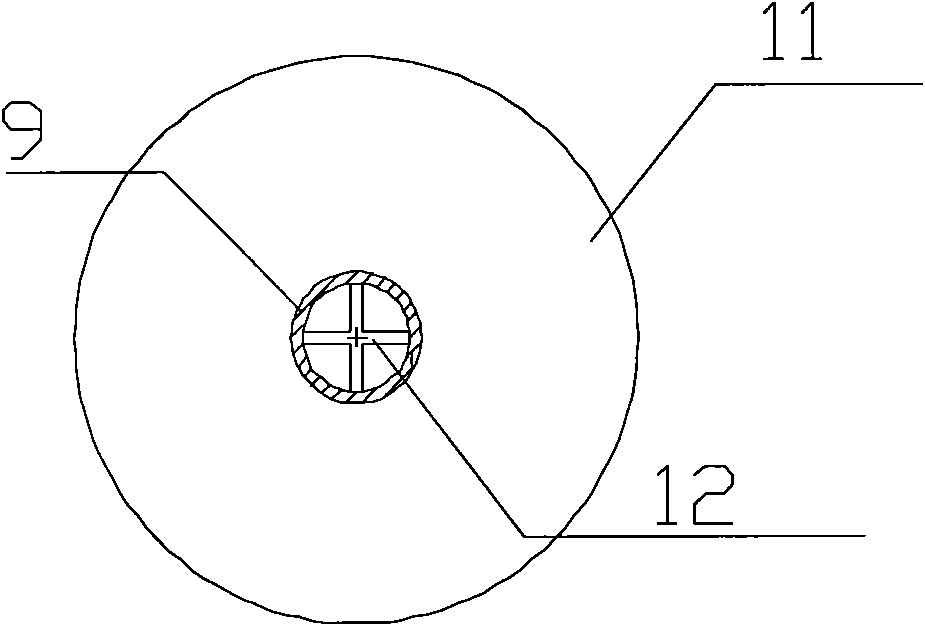

[0034] Such as figure 1 , figure 2 Shown:

[0035] Step 1. Install the vertical drainage filter pipe:

[0036] 1. High-pressure water gun impacts into holes

[0037] According to the design requirements, stake out the hole position of the vertical drainage filter pipe 2 in the area to be treated, and clean up the debris on the hole to be drilled; use a high-pressure water gun to impact the hole, the hole diameter is controlled within 15cm, and the hole depth is generally 6.5- About 7.0 meters. The high-pressure water gun impact hole-forming construction technology can overcome the difficulty of inconvenient movement of traditional board-making machines in soft soil.

[0038] 2. Press buried vertical drainage filter pipe 2

[0039] The vertical drainage filter pipe 2 is covered with a geotextile bag, and the geotextile bag is placed under the end plate 10 of the vertical drainage filter pipe 2, and the geotextile bag is fixed on the filter rod thread 13 with iron wire or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com