Actively-controlled exhaust muffler of autonomously-inverting internal-combustion engine

An exhaust muffler and internal combustion engine technology, applied in the mechanical field, can solve the problems of large electric power consumption of the active muffler, large power loss of the passive muffler, complex structure of the active muffler, etc., and achieve the effects of energy saving, simple structure and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

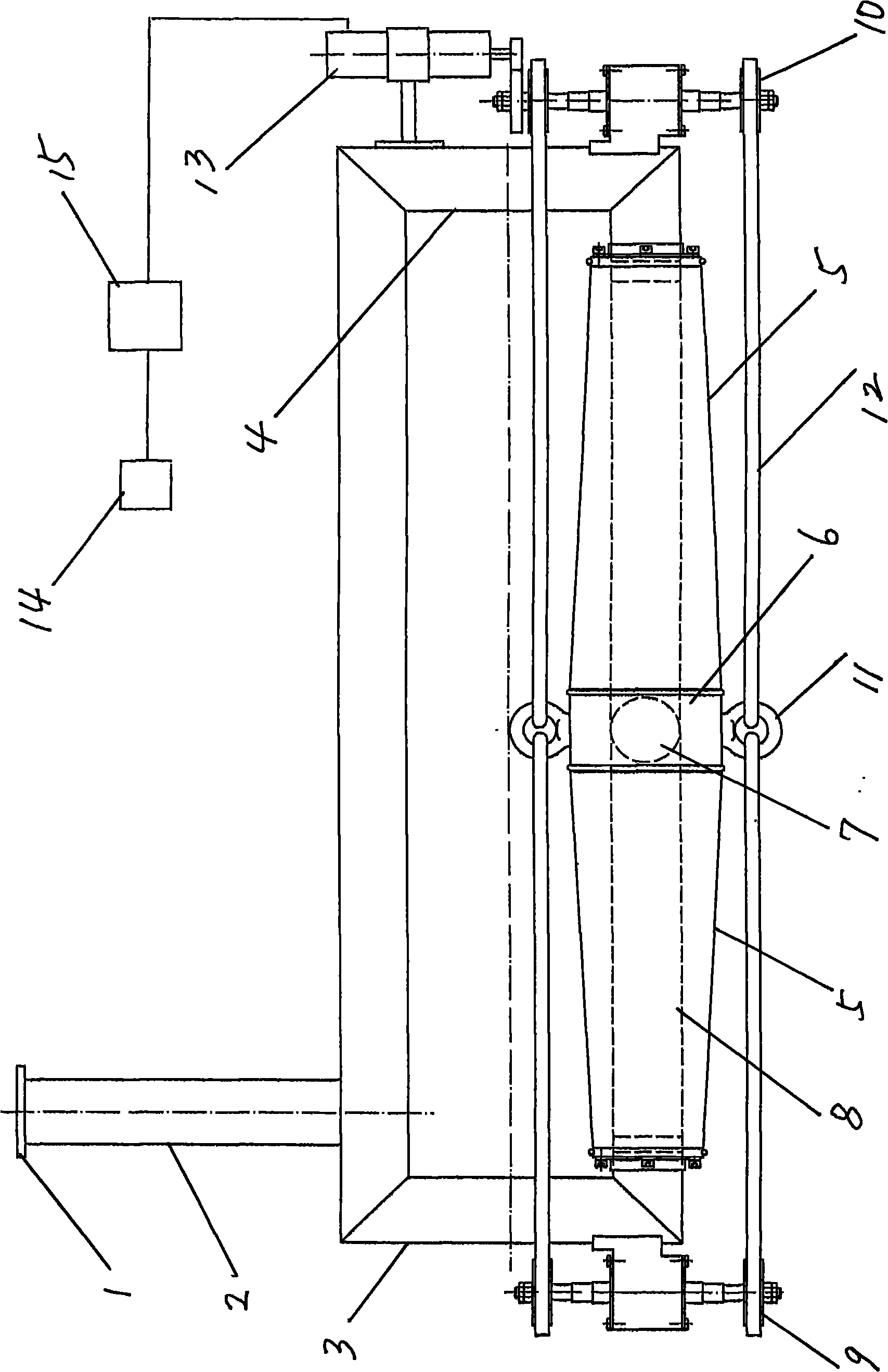

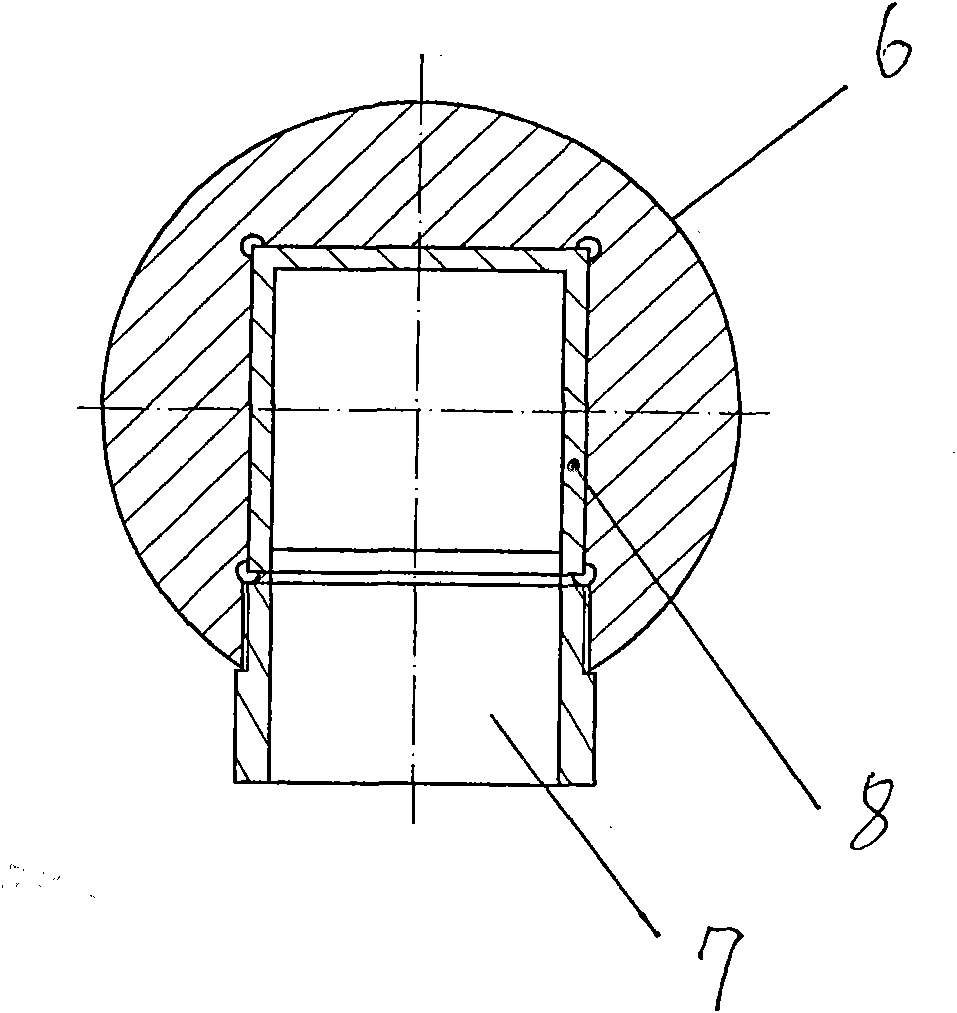

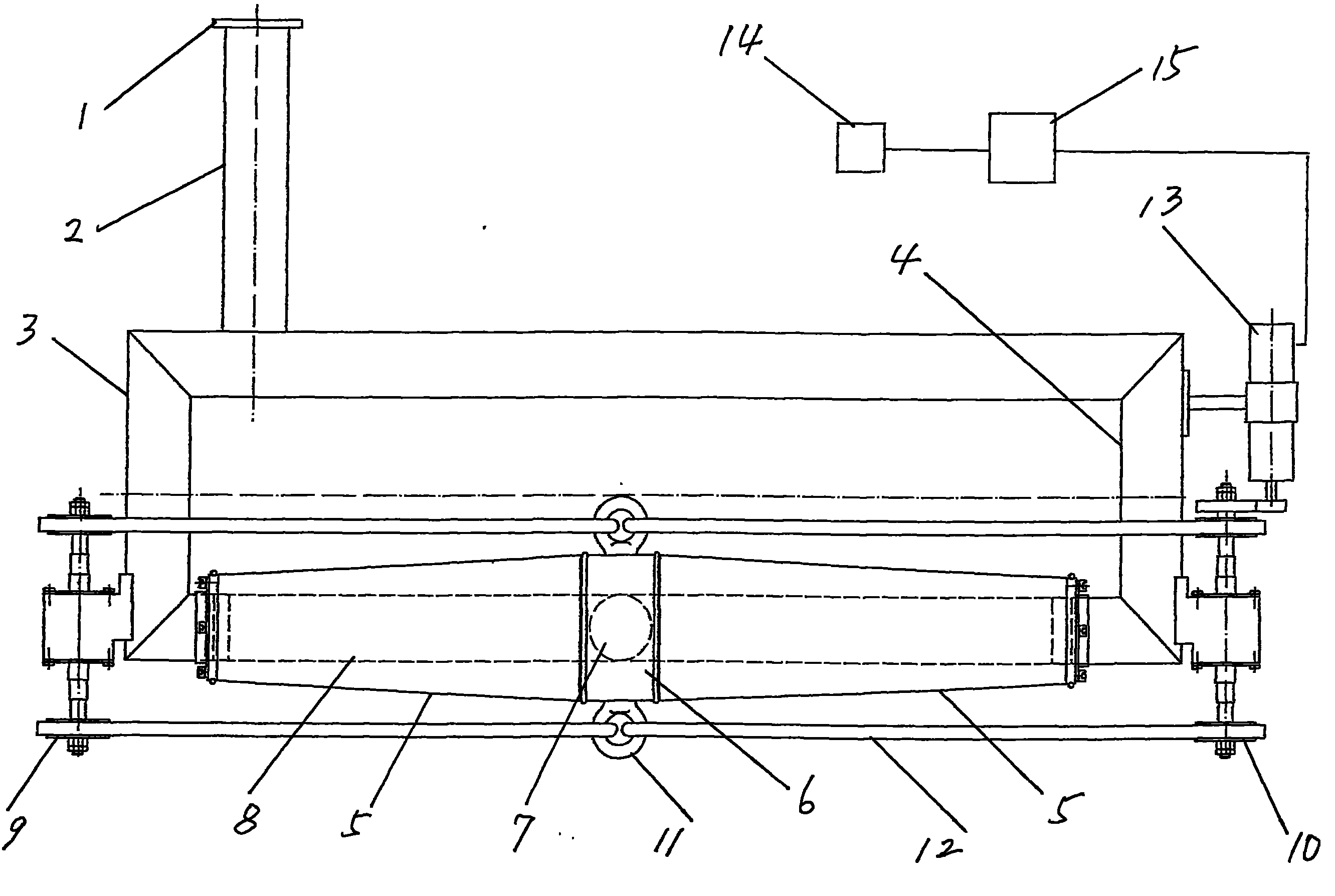

[0009] refer to figure 1 , figure 2 , the muffler pipeline circuit in the present invention includes a joint 1 connected to the three-way catalytic converter, a cylinder exhaust introduction pipe 2 connected to the joint, two branch pipes connected to the output end of the introduction pipe 2 and separated in a straight line relative to the introduction pipe. The air pipes 3 and 4 are straightly connected to two sections of corrugated telescopic pipes 5 on the opposite outlets of the branch air pipes 3 and 4 after they are bent. The opposite ends of the two sections of corrugated telescopic tubes are connected to the exhaust nozzle seat 6. The exhaust nozzle seat 6 has an axial and radial three-way inner cavity, and the radial through cavity is connected to an exhaust nozzle 7 formed by a protruding pipeline. The spout seat slideway 8 is a groove-shaped rod with an opening on one side of the rectangular section. The groove-shaped opening of the slideway 8 is in the same dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com