Piston-type deep sea water pressure compensation energy accumulator

A technology of hydraulic compensation and accumulator, applied in mechanical equipment and other directions, can solve the problems of increasing the weight and space of the blowout preventer group, increasing the manufacturing cost of equipment, etc., and achieves the effects of good sealing, reduced weight and low friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

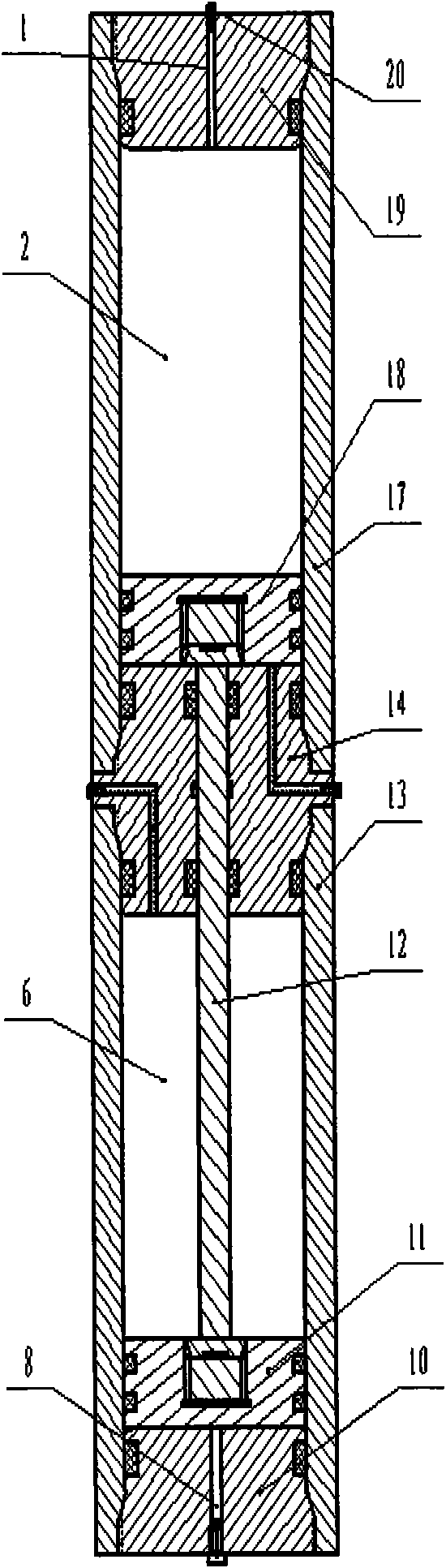

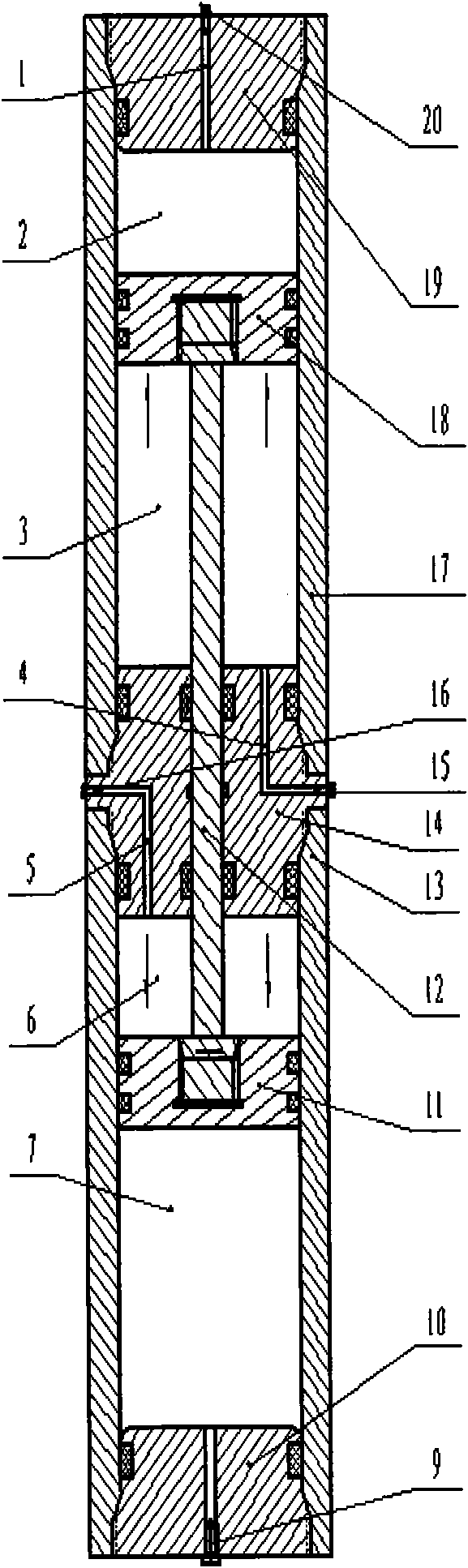

[0033]Embodiment 1: Taking a piston-type deep sea water pressure compensating accumulator with a volume of 52L and a working pressure of 35MPa as an example, the present invention will be further described in detail.

[0034] refer to Figure 1a . The deep sea water pressure compensation accumulator of the present invention is mainly composed of an air cavity end cover 19, an air charging valve 20, an upper piston 18, an upper housing 17, a connecting partition 14, a sea water filter 16, a hydraulic valve 15, a piston rod 12, a lower Piston 11, vacuum chamber end cover 10, sealing plug 9 are formed.

[0035] A cylindrical upper shell 17 and a lower shell 13 are respectively fixed at both ends of the cylindrical connecting partition 14 . The inner diameter of the upper casing 17 and the lower casing 13 is 305 mm, the length is 1200 mm, and the wall thickness is 50 mm;

[0036] An air chamber end cover 19 is threadedly fixed on the other end of the upper housing 17, and the ai...

Embodiment 2

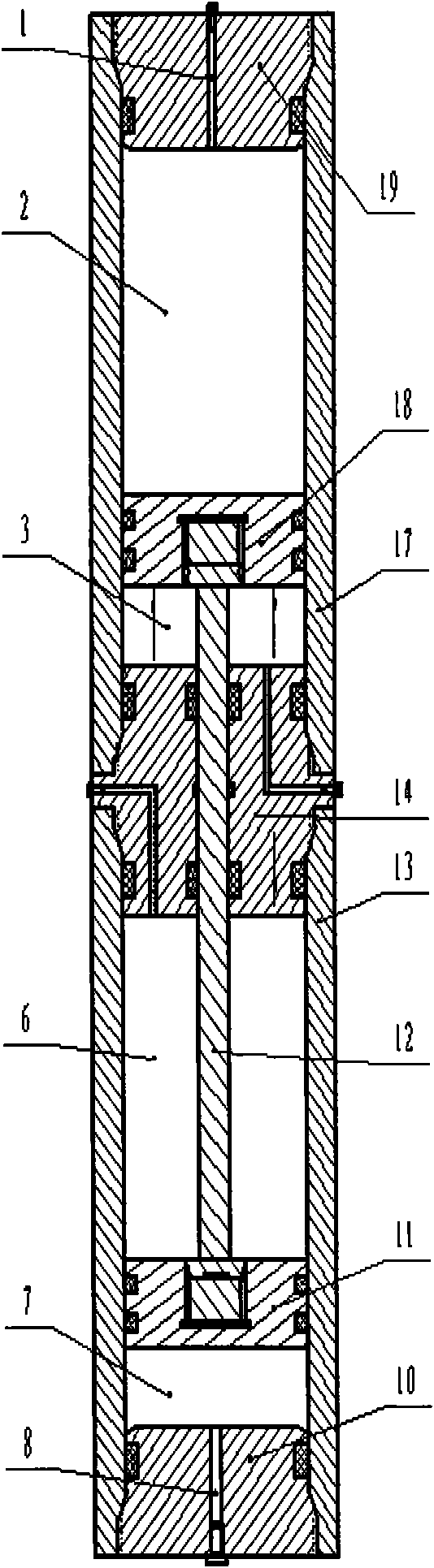

[0052] Embodiment 2: see image 3 . Embodiment 2 is basically the same as Embodiment 1, except that the inner diameter ratio of the upper casing 17 and the lower casing 13 is 1:2. The diameter ratio of the upper piston 18 to the lower piston 11 is 1:2. The connecting threads connecting the two ends of the partition plate 14 are correspondingly changed at the same time, so that the upper casing 17 and the lower casing 13 can be connected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com