Fully-automatic biomass burner

A biomass and burner technology, used in solid heating fuels, household cooking utensils, sustainable buildings, etc., can solve the problems of low material utilization rate, high material consumption, cumbersome operation, etc., and achieve high combustion efficiency, simple operation, and elimination of Effects of Arthritis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

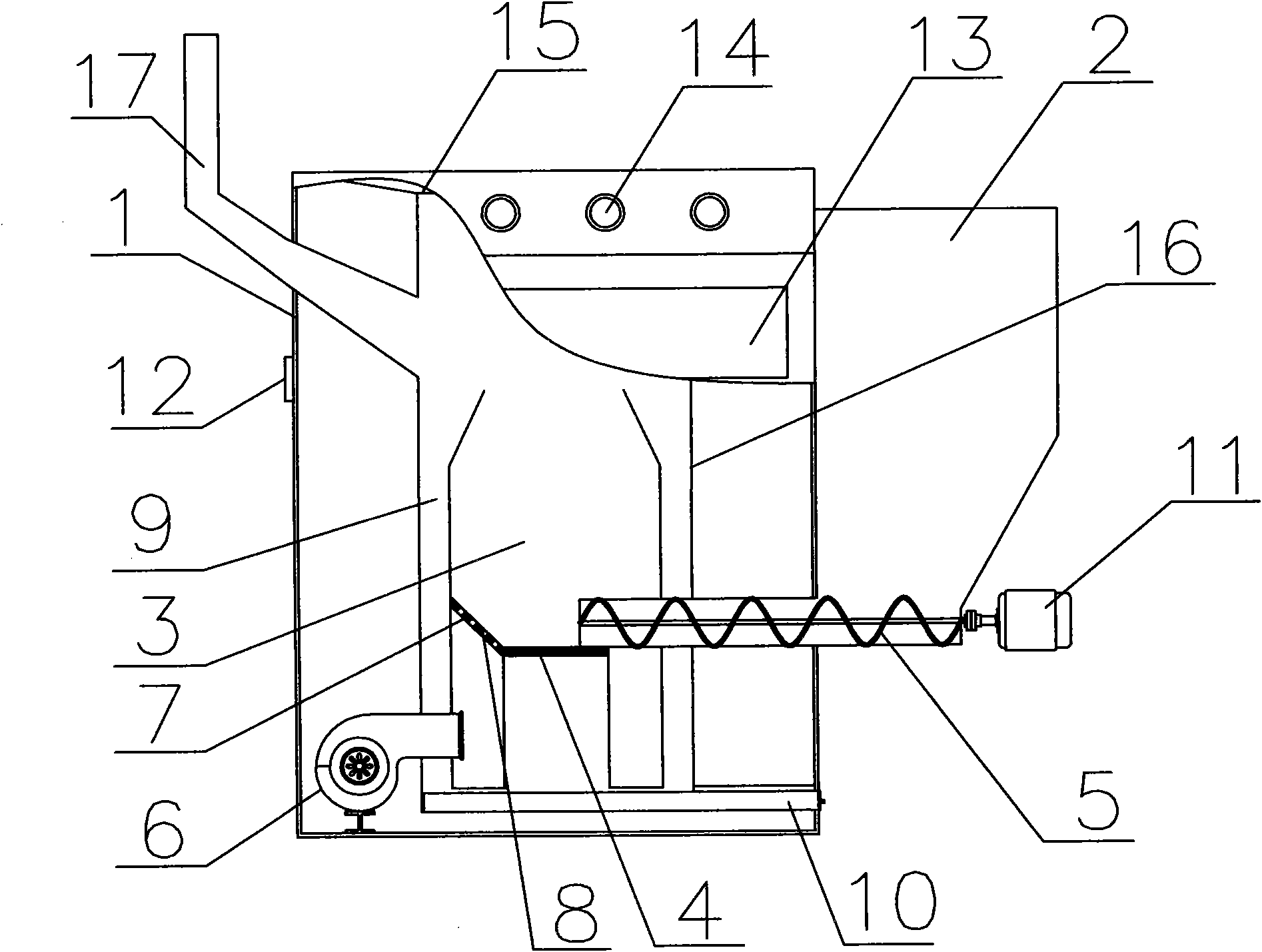

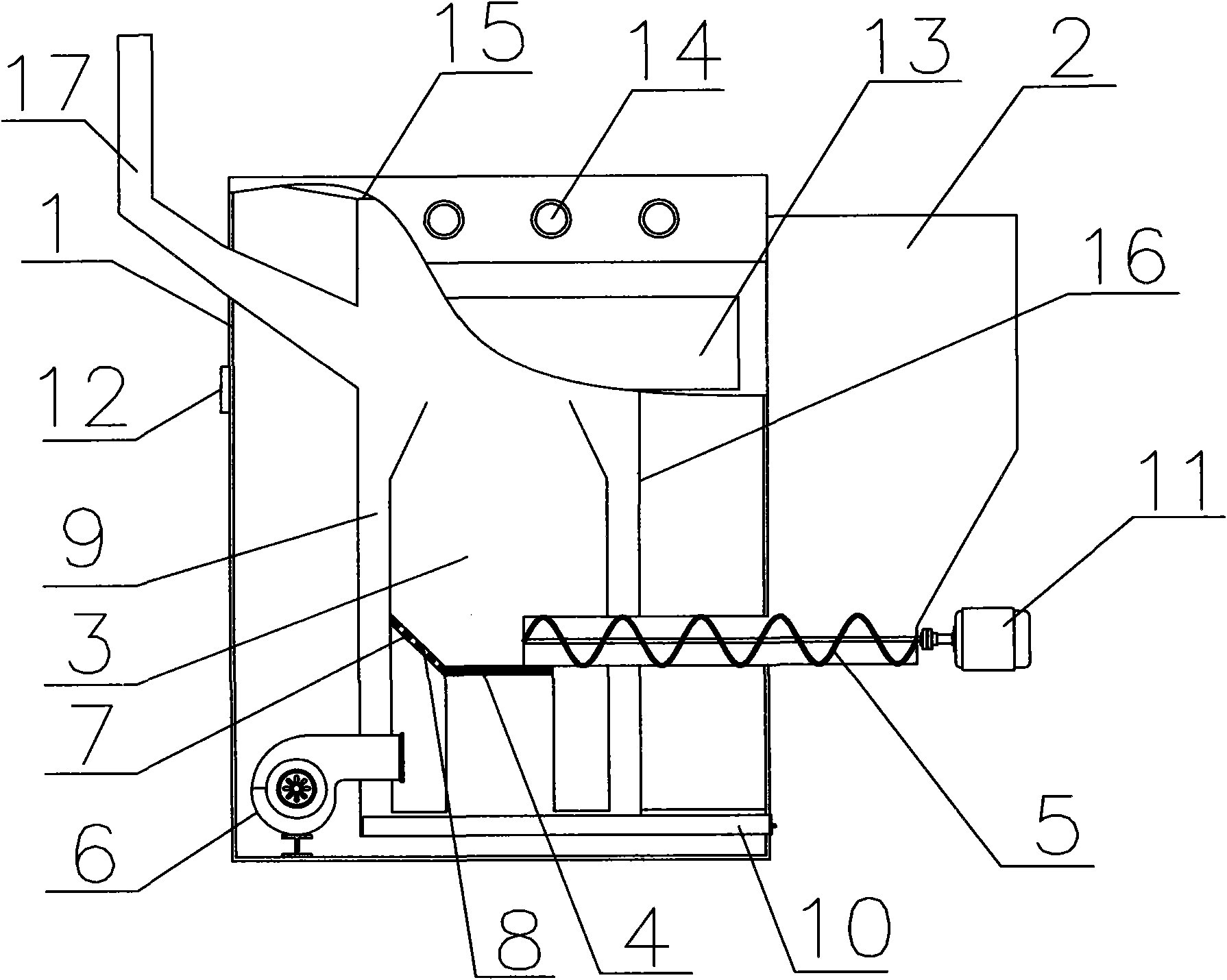

[0011] like figure 1 As shown, the fully automatic biomass burner includes an outer casing 1 with a side wall and a furnace body 16, the furnace body 16 is arranged in the outer casing 1, and a storage bin 2 is arranged on one side of the outer casing 1, Combustion chamber 3 is set in body of heater 16, ash removal chamber 9 is set between combustion chamber 3 and body of heater 16, old ash bin 10 is set between the bottom of body of heater 16 and the bottom of combustion chamber 3; The ignition plate 4 is arranged inside, and the auger 5 is arranged below the storage bin 2, the feed end of the auger 5 is connected to the lower end of the storage bin 2, the discharge end of the auger 5 is arranged in the combustion chamber 3, and the auger 5 The outer end of 5 is connected with small motor 11, and grate plate 7 is set between ignition plate 4 and combustion chamber 3, and one end of grate plate 7 is connected on the combustion chamber 3, and the other end of grate plate 7 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com