System and array for tracking solar energy linearly

A tracking system and solar energy technology, which are applied in the field of linear tracking where the focus of solar energy tracking is a straight line, and the field of forming an array of tracking and its utilization, can solve the problem of non-movement of the focal line, and achieve the effect of overcoming the small load and expanding the technology and scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1: Fresnel mirror solar line focus tracking system

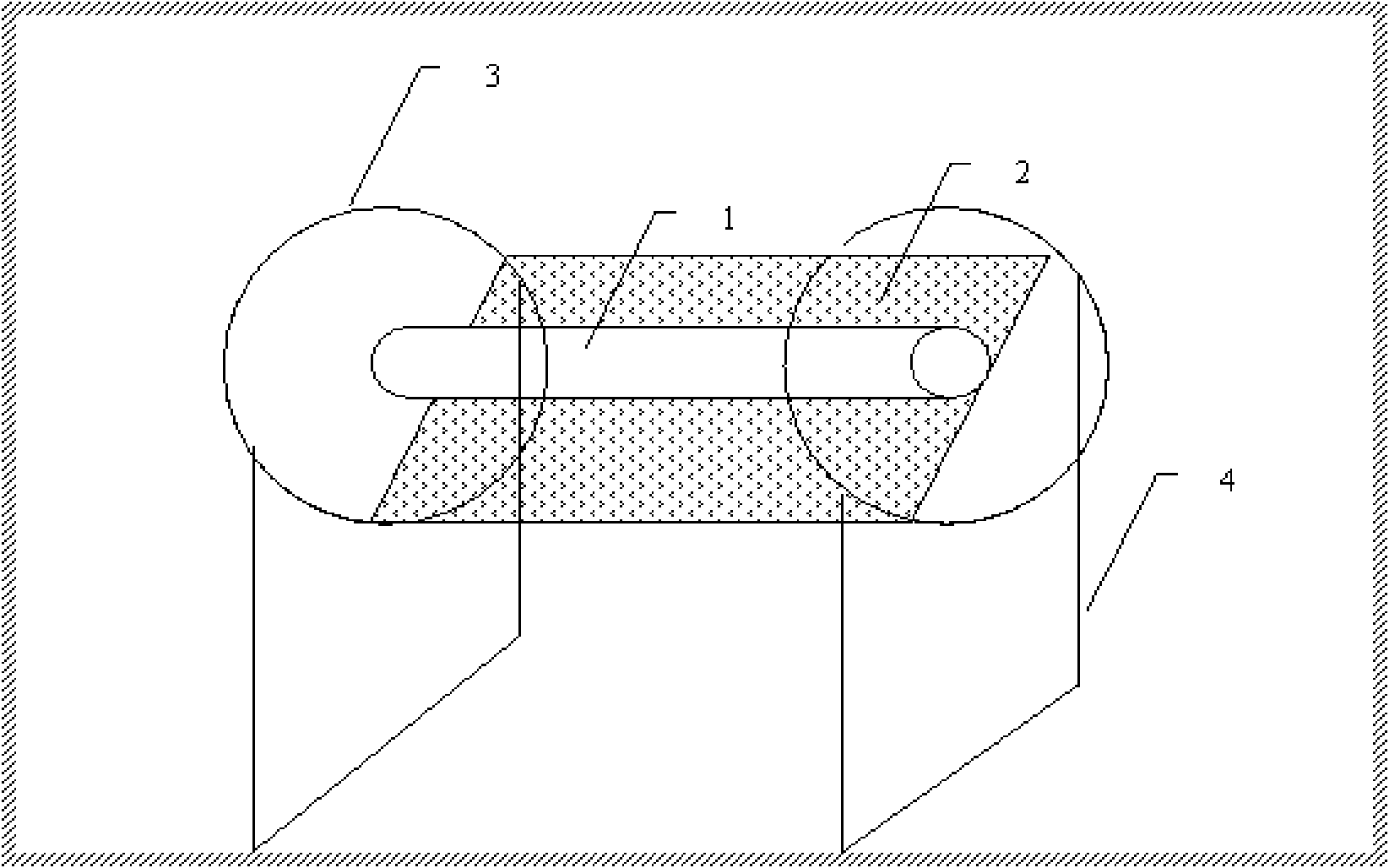

[0070] A linear focusing Fresnel reflector (1) is adopted, and the solar energy utilization device is a heat pipe arranged inside the vacuum, and a solar selective coating is arranged on the heat pipe, and the Fresnel reflector is arranged on the rings at both ends, The Fresnel reflector can move along the orbit of the ring, the vacuum heat collecting tube is fixed on the ring, and the vacuum heat collecting tube remains motionless during the operation of the Fresnel reflector.

Embodiment 2

[0071] Embodiment 2: Parabolic mirror arc tracking system

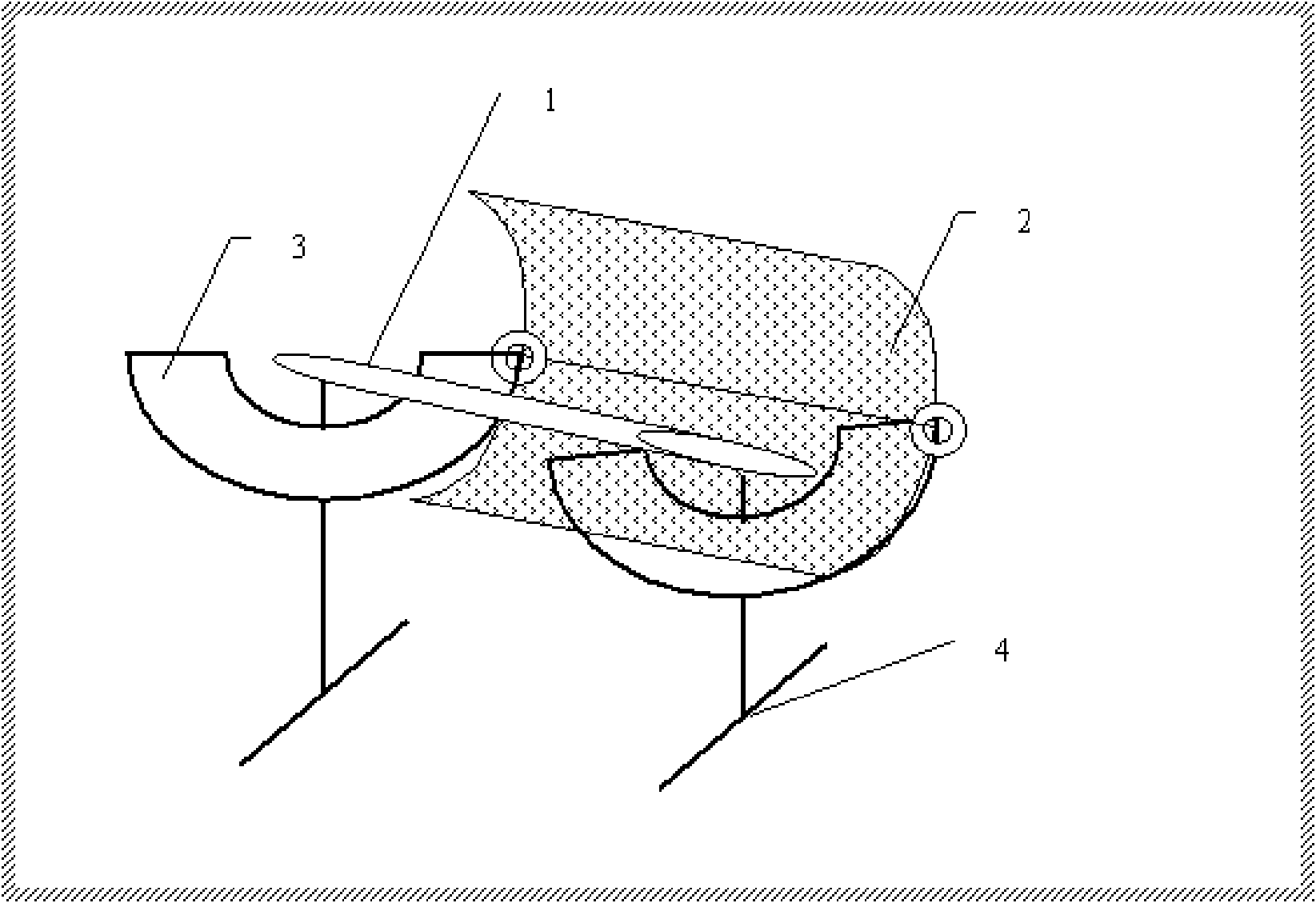

[0072] The solar mirror is a parabolic mirror (2), and the solar energy utilization device (1) is a heat exchange tube. The fluid enters from one end of the heat exchange tube and flows out from the other end. The fluid uses heat transfer oil, and the parabolic mirror is arranged in an arc-shaped On the guide rail, the parabolic mirror can rotate along the arc-shaped parabolic mirror, facing east in the morning, facing the sky at noon, and facing west in the evening, so that the parabolic surface and the sunlight can be kept perpendicular to each other, and the heat exchange tubes are fixed in the arc. On the guide rail, the curved guide rail has a bracket to provide support.

Embodiment 3

[0073] Embodiment 3: Ring-shaped parabolic tracking system with counterweight

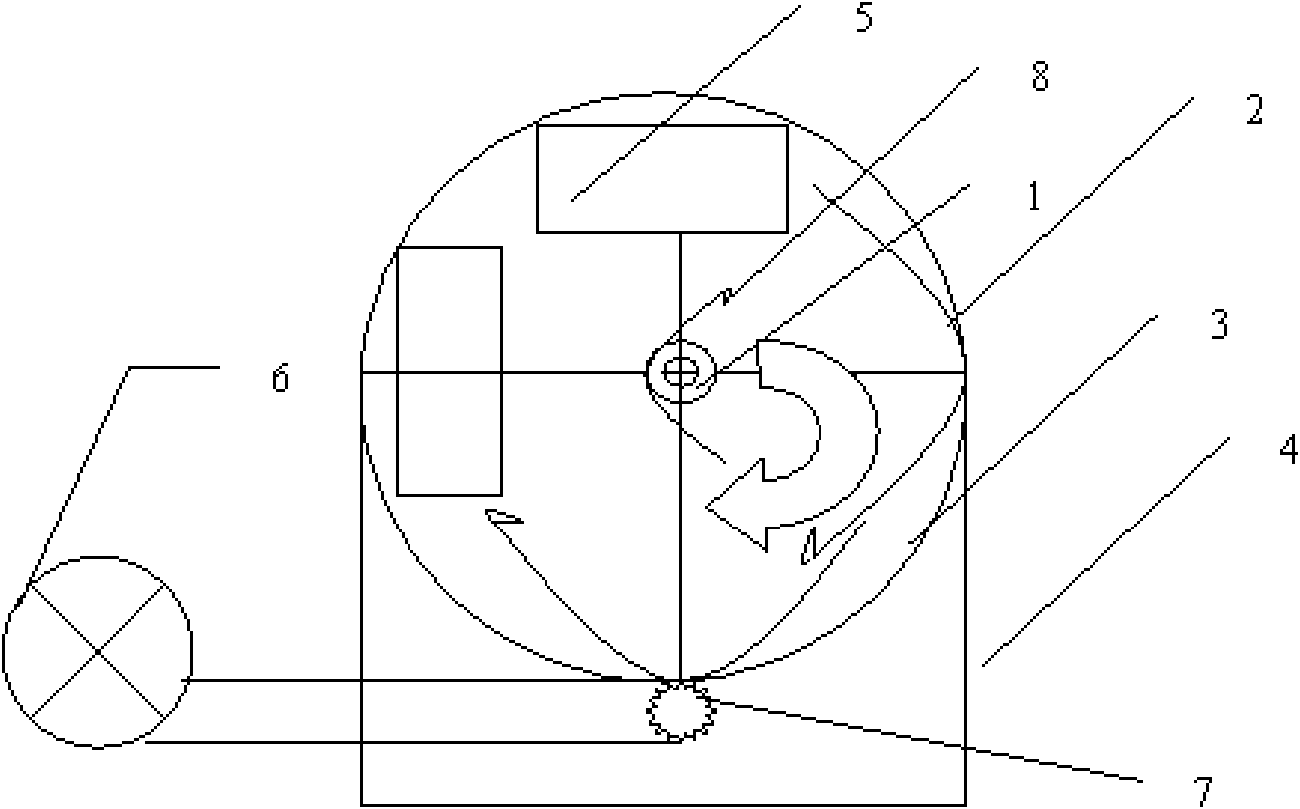

[0074] Such as image 3 As shown, this figure is a side view, the solar mirror (2) is a parabolic reflector; the solar energy utilization device (1) is a solar photovoltaic and photothermal comprehensive utilization system, and the monocrystalline silicon solar panel is arranged inside the vacuum tube At the same time, a water cooling device is provided to provide a heat dissipation device for the solar panel, so that both focused photovoltaic power generation and hot water utilization can be realized. Outside the vacuum tube of monocrystalline silicon, a secondary reflector (8) is also provided. Provide secondary reflected solar light for monocrystalline silicon; the paraboloid and the counterweight (5) form a lever with the focal axis of rotation as the fulcrum, and the paraboloid follows the sun along the direction of the arrow in the figure from morning to noon; the paraboloid is fixed in a cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com