Method for monitoring oil well fracturing microseismic ground-borehole crack

A microseismic and surface technology, applied in the field of oil well fracturing microseismic surface-well fracture monitoring, can solve the problems of difficult monitoring, high cost, and inability to meet deep well fracturing fracture monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

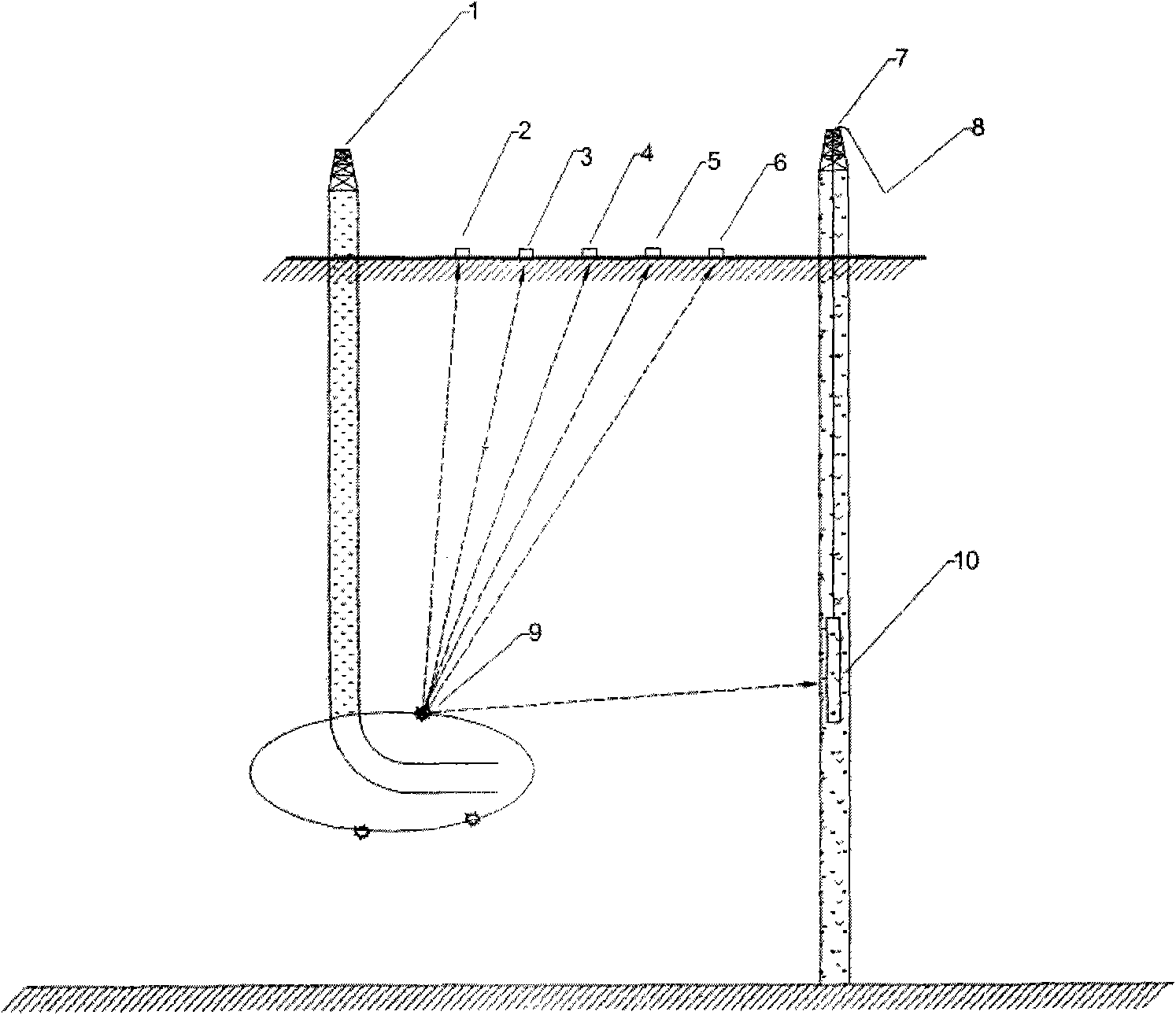

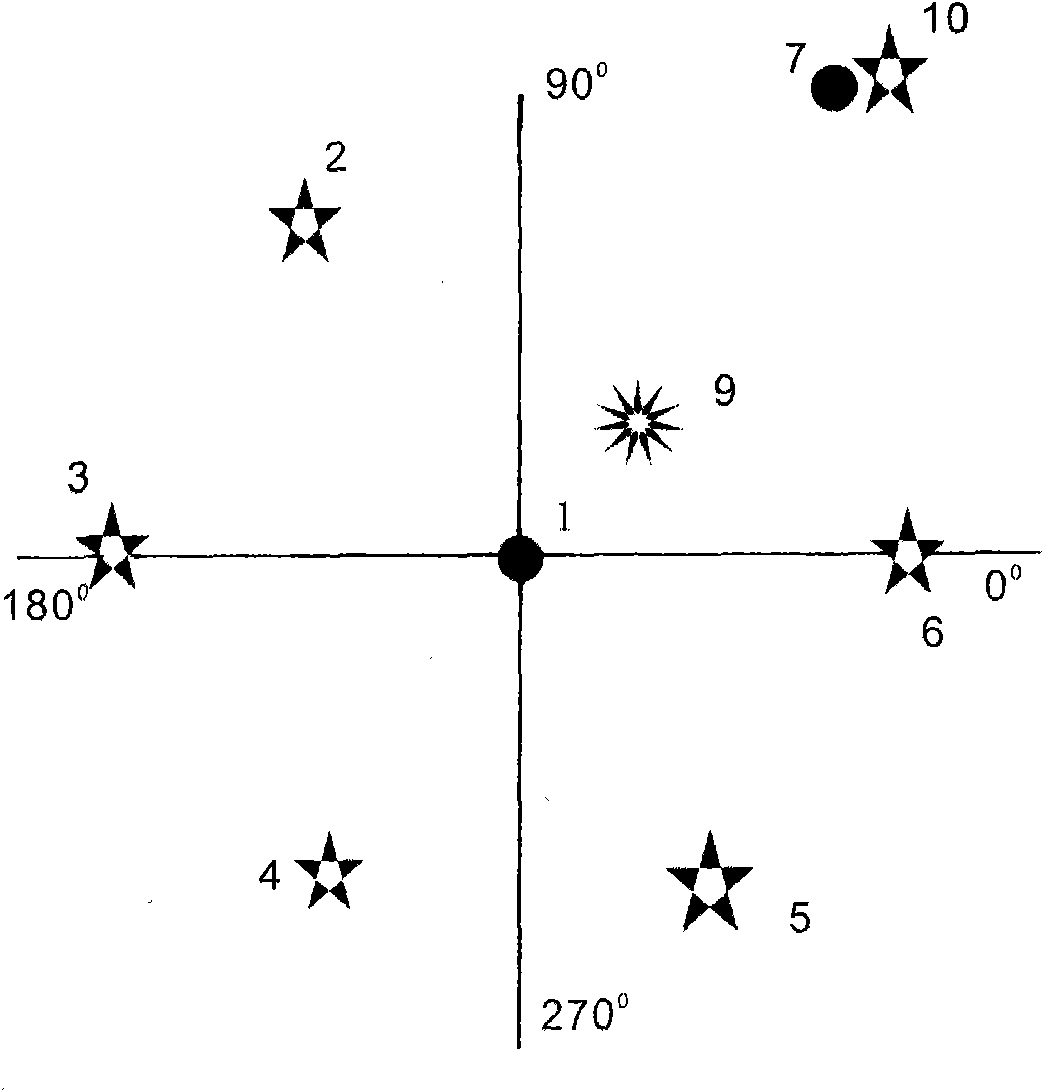

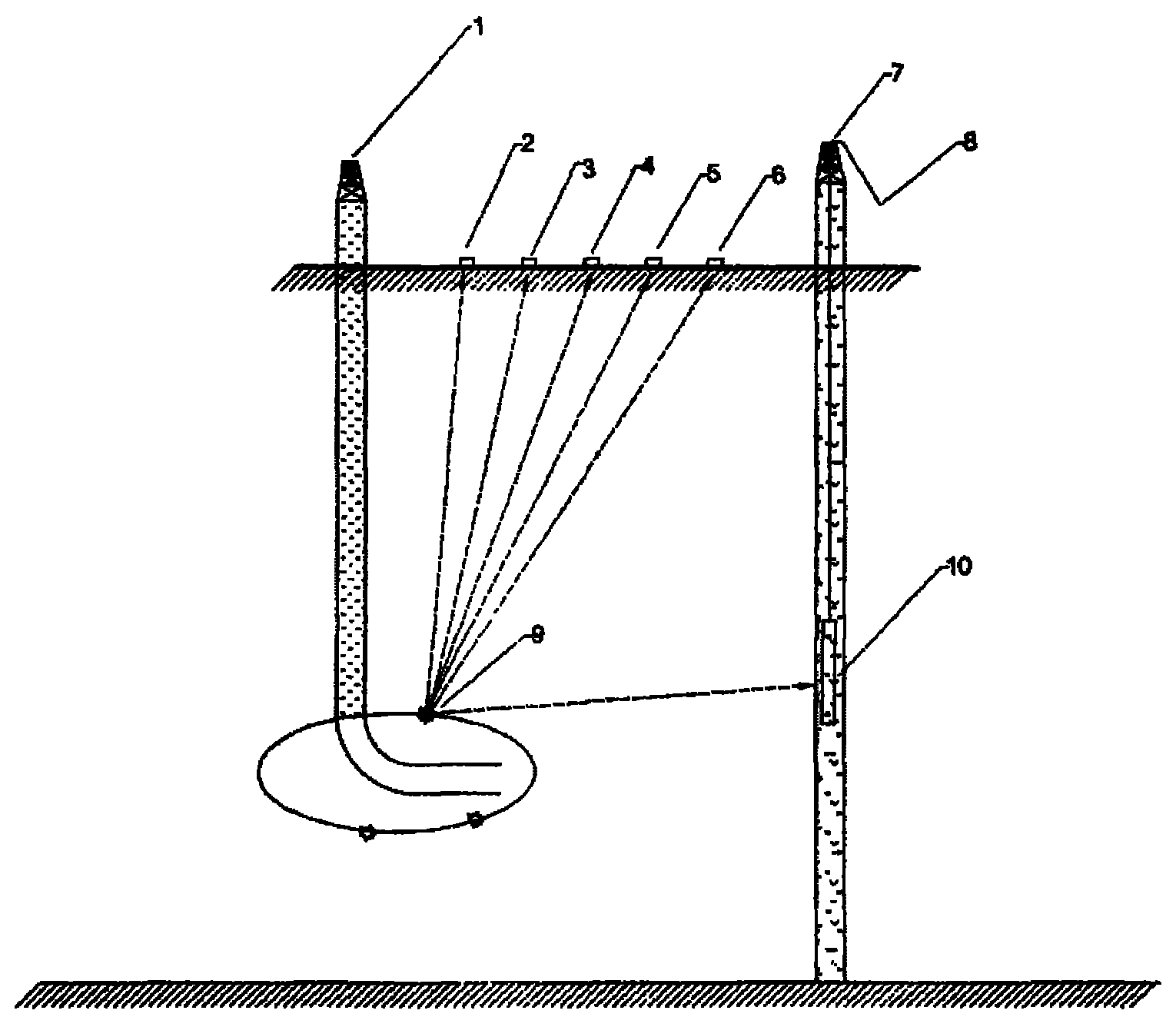

[0007] Firstly, five ground vibration pickups (2, 3, 4, 5, 6) should be distributed radially around the fracturing well 1, and a monitoring well 7 should be found within 600m around the fracturing well 1, and the fracturing monitoring and The three-core cable 8 on the command vehicle is connected with the vibration pickup 10 in the well, and then the vibration pickup 10 in the well is put into the 1 / 2 depth of the fracturing well 1 fracturing layer. The vibration pickup 10 in the well adopts the most advanced acceleration sensor in the world as the front-end acquisition unit, and the minimum measurement accuracy is 10 -5 m / s 2 , which meets the requirements for measuring microseismic signals. There is a main control station of this system on the fracturing monitoring and command vehicle. The main control station adopts an industrial computer, runs WINDOWSXP operating system, and is connected with the main control station through a network interface through an adapter. The mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com