Cushion type operating platform for solar modules at later stage of production

A technology of solar modules and consoles, which is applied in the manufacture of electrical components, semiconductor devices, and final products. It can solve problems such as battery sheet rupture and battery components being bent under pressure, so as to ensure quality, facilitate storage, and reduce the probability of damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

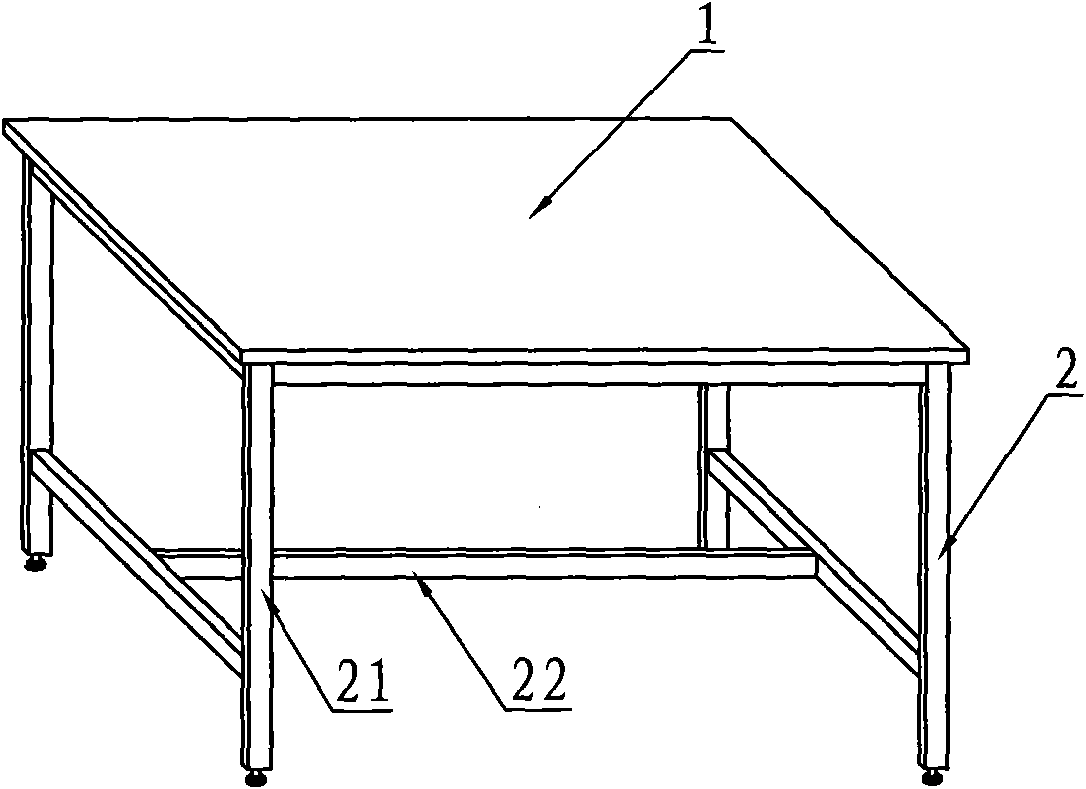

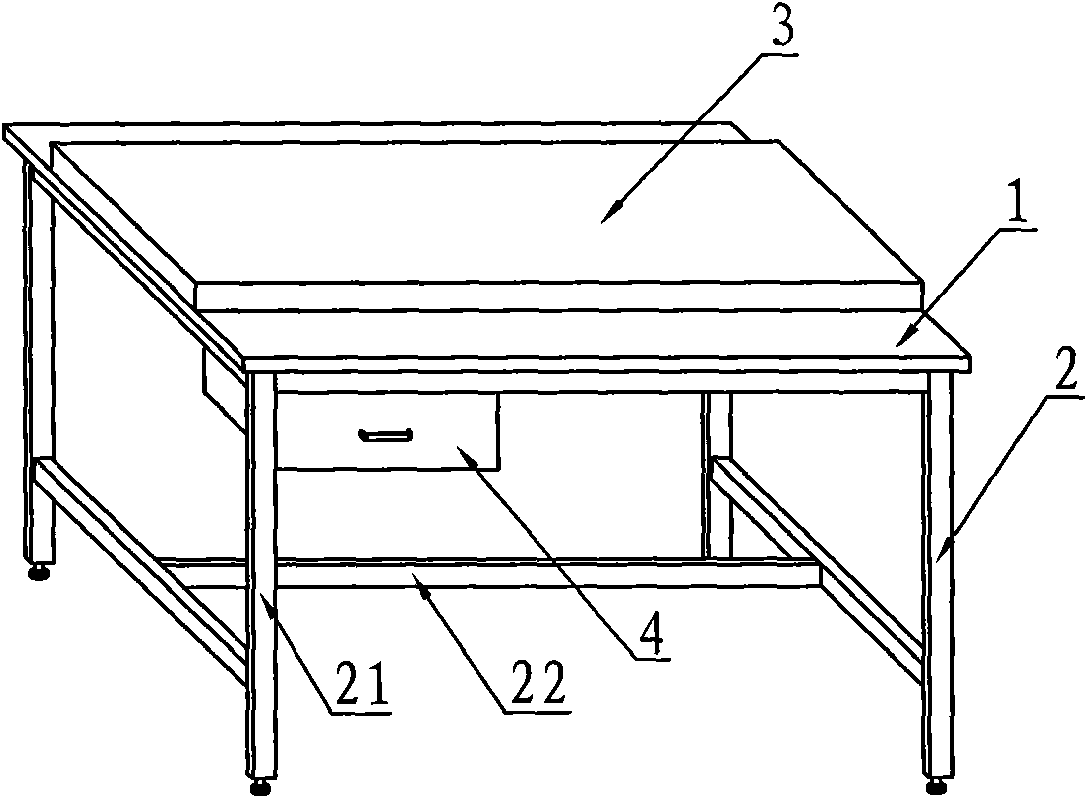

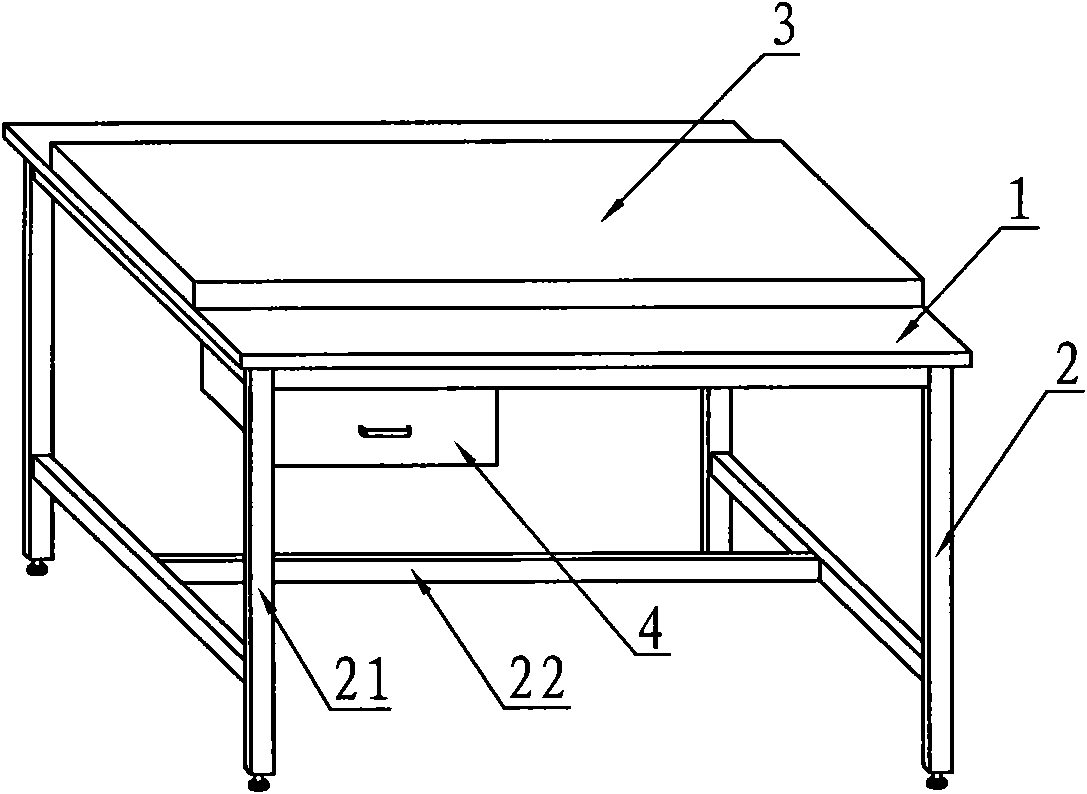

[0012] The post-production operation table of the cushion type solar module, such as figure 2 As shown, it includes a work surface 1, a support frame 2, a highly elastic cushion 3 and a drawer 4. The work surface 1 is horizontally installed on the top of the support frame 2, and the support frame 2 is a frame structure surrounded by four legs 21 of equal length. It is composed of an "I"-shaped reinforcing rod 22, and the "I"-shaped reinforcing rod 22 is fixed on the middle and lower sections of the four table feet 21. Two drawers 4 are arranged below the work surface 1, and the highly elastic cushion 3 is arranged on the Above the work surface 1, and located in the center of the work surface 1, the length and width of the work surface 1 are greater than the length and width of the solar cell module frame after the frame, and the length and width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com