Aerodynamic force meat filling food raw material suction conveyer

A technology of pneumatic power and raw materials, applied in sausage enema machines, processed meat, food science, etc., can solve the problems of pore wall oxidation and yellowing, pollution, and rough cutting surface, so as to ensure food hygiene and safety, easy to disassemble and clean, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

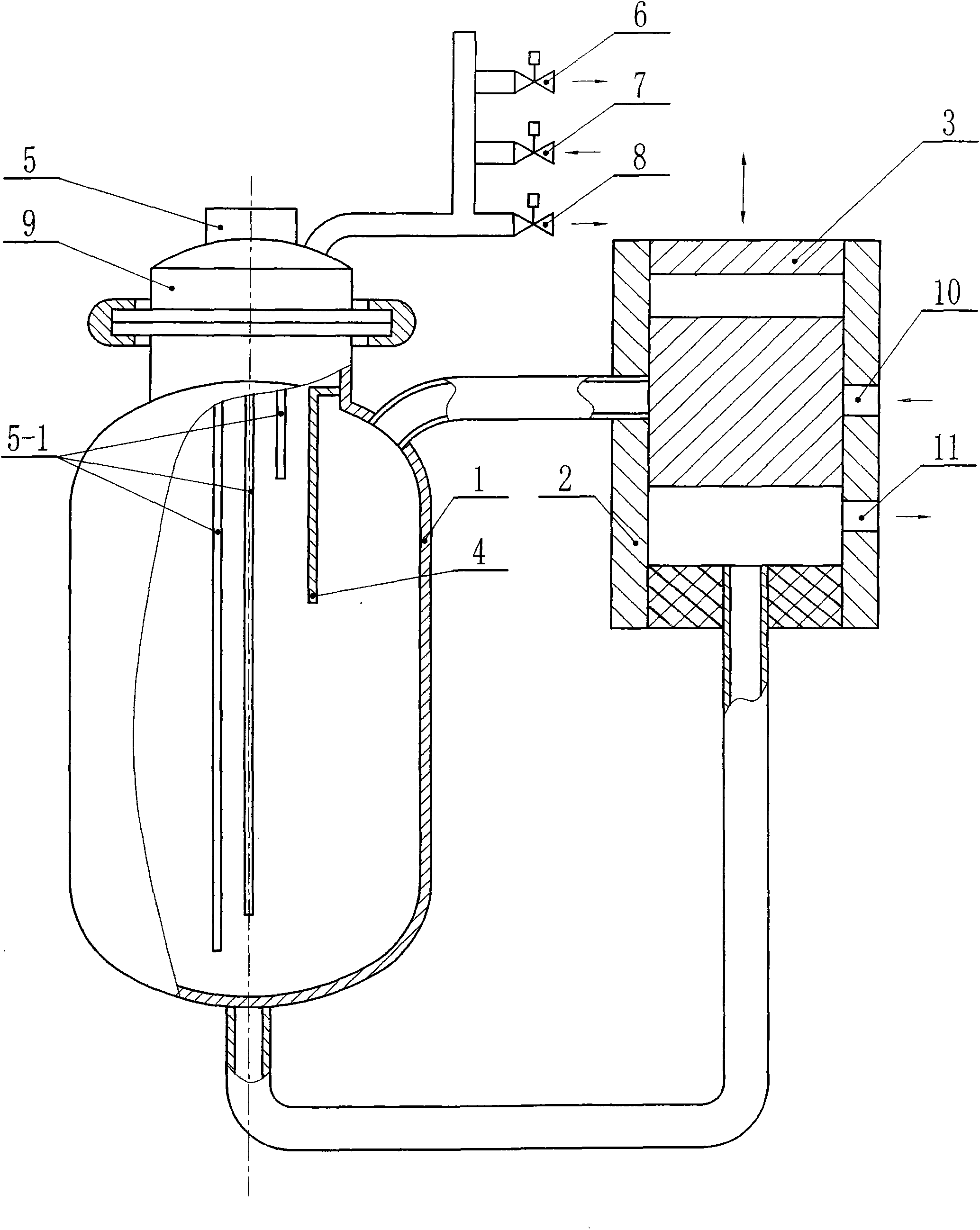

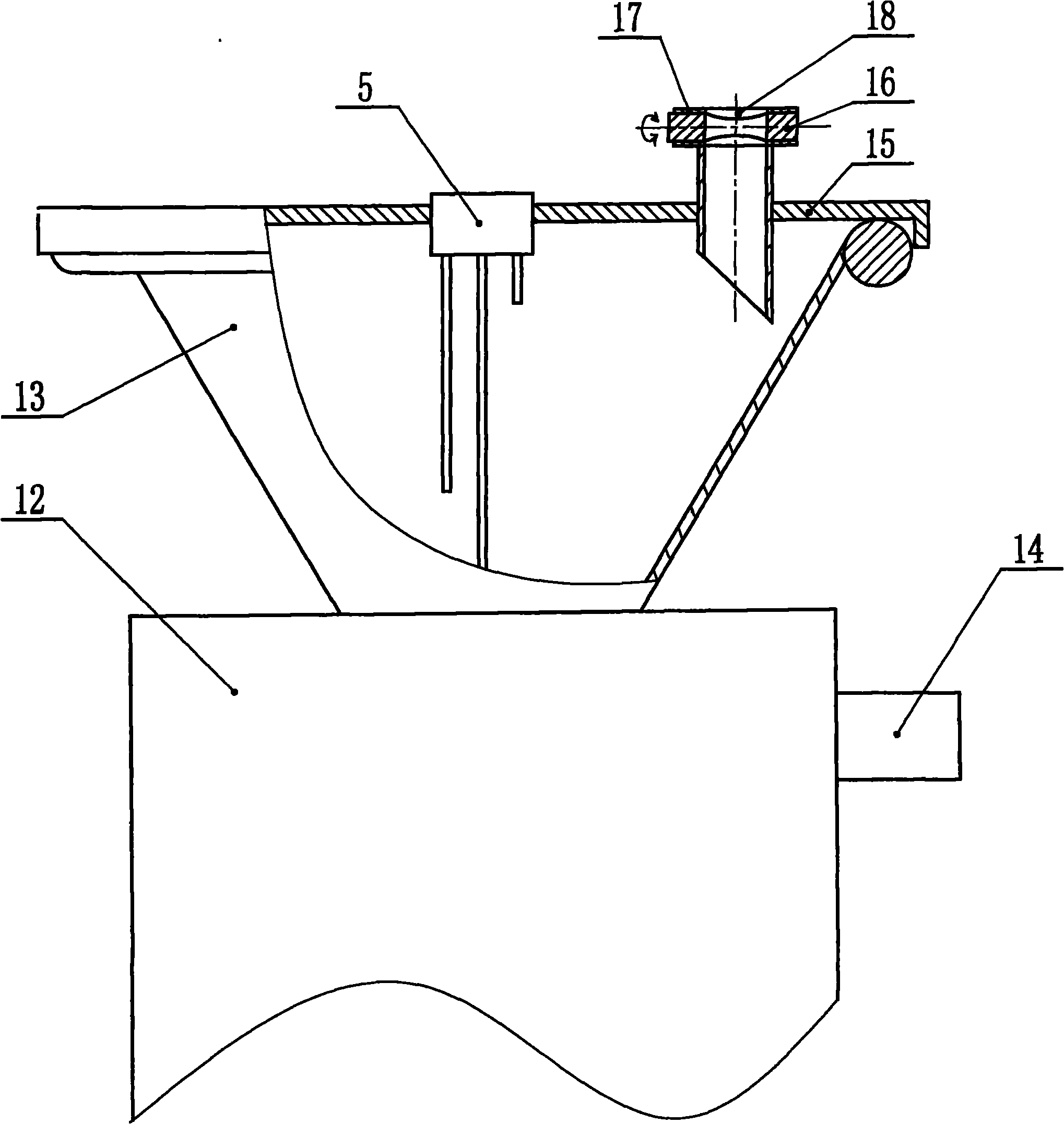

[0016] Meat filling food raw material suction machine and filling machine work together

[0017] The feed port (10) of the meat filling food raw material suction machine is connected with the suction pipe and inserted into the raw material of the raw material turnover car, the discharge port (11) is connected with the feed port (18) of the filling machine with a pipe, and the start Meat filling food raw material suction machine, the electric control valve (6) of the suction port is opened, the plunger (3) of the electric control plunger valve (2) moves downward, the feed port (10) is opened, and the discharge port (11 ) is closed, the vacuum pump starts to work, and when the negative pressure in the airtight container tank (1) reaches a certain negative pressure value, the raw material is sent into the airtight container tank (1) by the atmospheric pressure through the pipeline, and the raw material is in the airtight container When the tank body (1) rises to the design upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com