Eddy current sensor type automatic weld tracking control method

An eddy current sensor and automatic tracking technology, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of not too high control accuracy, difficulty in meeting requirements, difficulty in ensuring accuracy, etc., and achieve good welding processability, Easy to popularize and promote, control the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

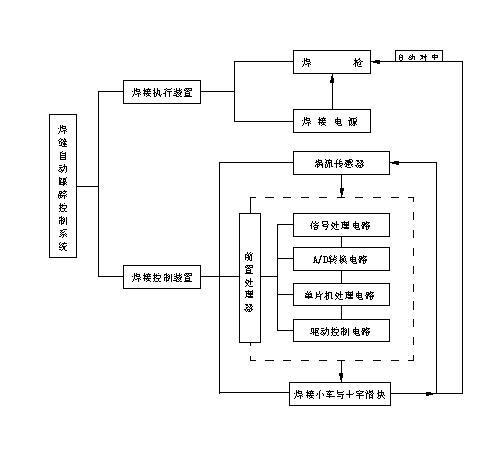

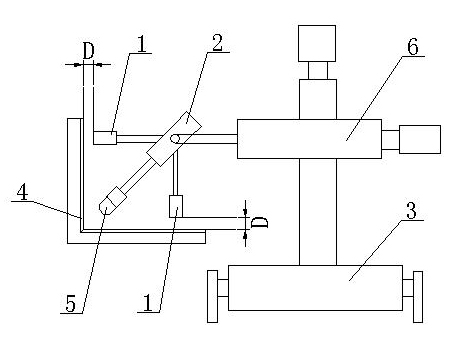

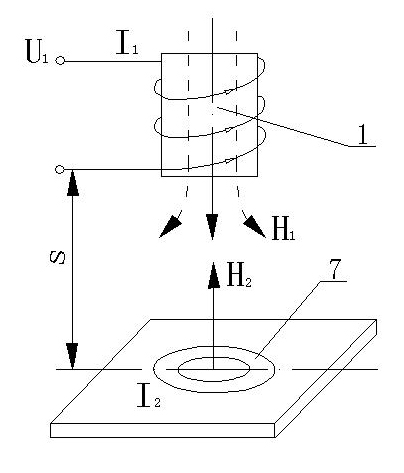

[0018] In conjunction with the accompanying drawings, the present invention adopts a control system comprising an eddy current sensor 1 installed on a welding torch, a welding execution device and a welding control device, and combines the non-contact linearized measurement characteristics of the eddy current sensor 1 to realize an eddy current sensor type The welding seam automatic tracking control method includes a welding execution device composed of a welding power supply and a welding torch 5, a welding control device composed of an eddy current sensor 1, a pre-processor, a welding trolley 3 and a cross slider 2, and the pre-processor A signal processing circuit, an A / D conversion circuit, a single-chip microcomputer processing circuit and a drive control circuit are set in the circuit, and the signal collected by the eddy current sensor 1 is converted into a voltage value signal output. During the processing, the signal processing circuit and the A / D conversion circuit are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com