Novel process for controlling waste residue and recycling resources in 1-anthraquinone production

A resource recovery and aminoanthraquinone technology, which is applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of waste residue accumulation and no good recycling methods, so as to improve efficiency and eliminate hidden dangers of environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A new process for 1-aminoanthraquinone production waste residue treatment and resource recovery, the method includes two steps:

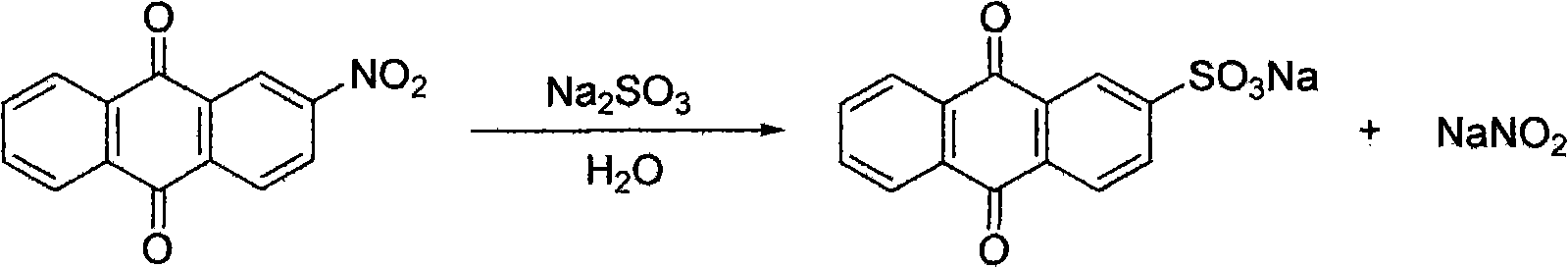

[0014] A) Reacting the waste residue with an aqueous solution of sodium sulfite to convert the components containing β-nitroanthraquinone in the waste residue into water-soluble substances, which are removed by filtration. After the filter cake is dried, it is used for the next operation;

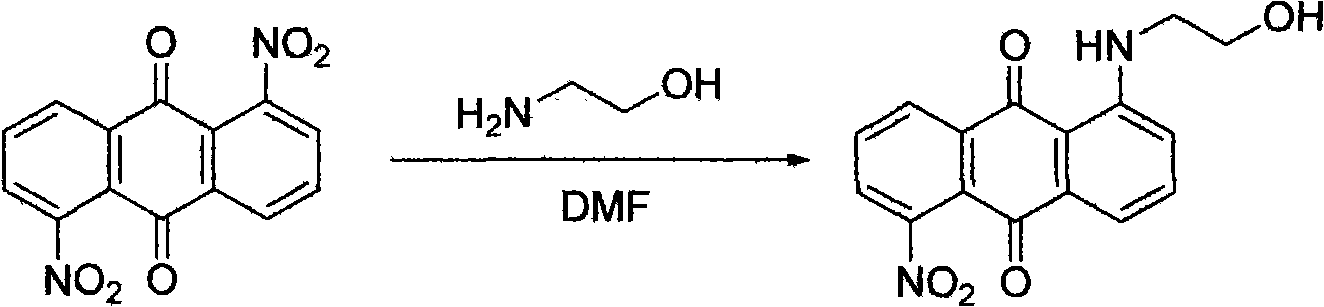

[0015] B) the dried filter cake reacts with an organic amine in N, N-dimethylformamide at high temperature and cools and crystallizes. After the crystals are collected, a product containing 88% of 1-nitroanthraquinone can be obtained, which The quality is better than crude nitroanthraquinone obtained by direct nitration of anthraquinone.

[0016] Wherein, the component containing β-nitroanthraquinone includes 2-nitroanthraquinone, 1,6-; 1,7-; 2,6-; 2,7-four dinitroanthraquinones. They can all be removed by reacting with sodium sulfite solution to generat...

Embodiment 2

[0027] A new process for 1-aminoanthraquinone production waste residue treatment and resource recovery, the method includes two steps:

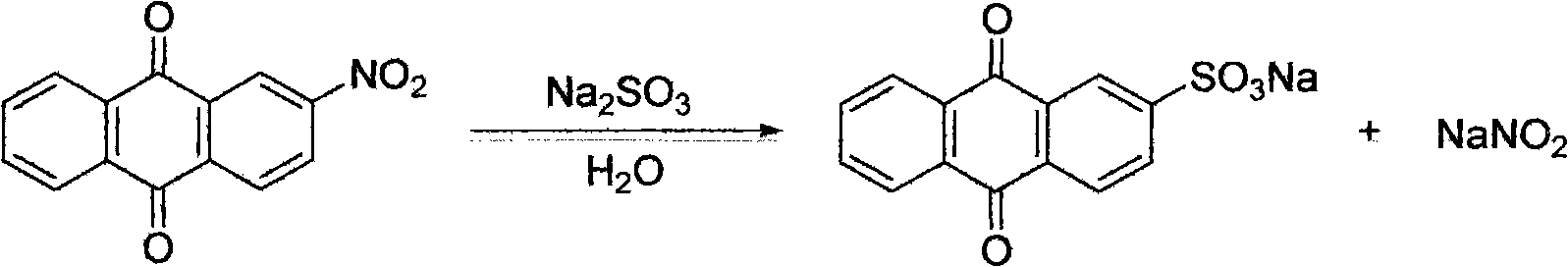

[0028] A) Reacting the waste residue with an aqueous sodium sulfite solution to convert the nitroanthraquinone-containing components in the waste residue into water-soluble substances, which are removed by filtration. After the filter cake is dried, it is used for the next operation;

[0029] B) the dried filter cake reacts with an organic amine in N, N-dimethylformamide at high temperature and cools and crystallizes. After the crystals are collected, a product containing 88% of 1-nitroanthraquinone can be obtained, which The quality is better than crude nitroanthraquinone obtained by direct nitration of anthraquinone.

[0030] Wherein, the component containing β-nitroanthraquinone includes 2-nitroanthraquinone, 1,6-; 1,7-; 2,6-; 2,7-four dinitroanthraquinones. They can all be removed by reacting with sodium sulfite solution to generate wat...

Embodiment 3

[0041] A new process for 1-aminoanthraquinone production waste residue treatment and resource recovery, the method includes two steps:

[0042] A) Reacting the waste residue with an aqueous sodium sulfite solution to convert the nitroanthraquinone-containing components in the waste residue into water-soluble substances, which are removed by filtration. After the filter cake is dried, it is used for the next operation;

[0043] B) the dried filter cake is reacted with an organic amine in N, N-dimethylformamide at high temperature and crystallized by cooling. After the crystals are collected, a product containing 88% of 1-nitroanthraquinone can be obtained, which The quality is better than crude nitroanthraquinone obtained by direct nitration of anthraquinone.

[0044] Wherein, the component containing β-nitroanthraquinone includes 2-nitroanthraquinone, 1,6-; 1,7-; 2,6-; 2,7-four dinitroanthraquinones. They can all be removed by reacting with sodium sulfite solution to generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com