Fully-mechanized operating large methane tank (set) and methane tank class group

A biogas digester group and biogas digester technology, applied in biochemical instruments, biochemical equipment and methods, gas production bioreactors, etc., can solve the problems of no temperature adjustment, high-efficiency gas production, etc., and achieve simple operation and high gas production effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

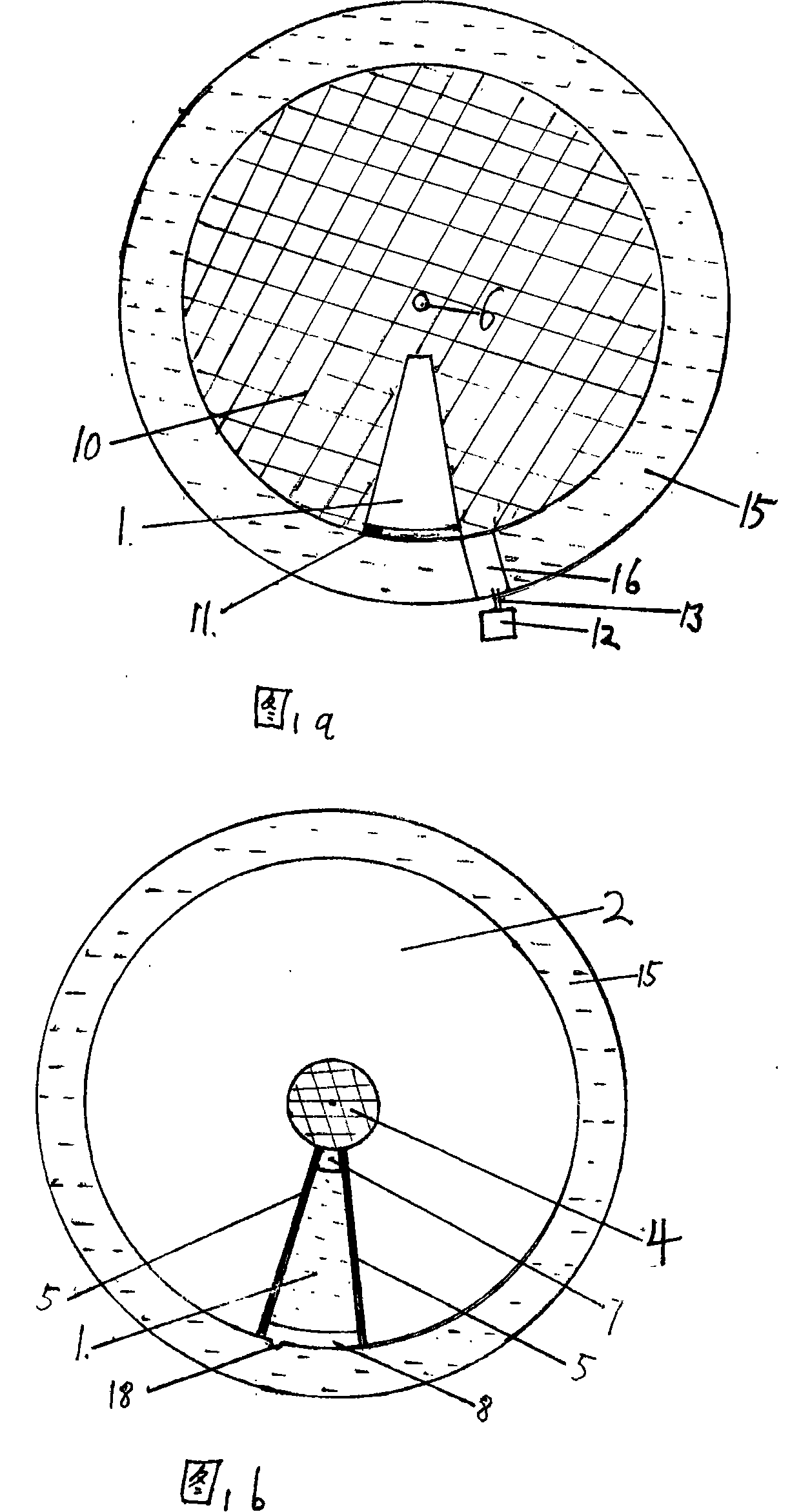

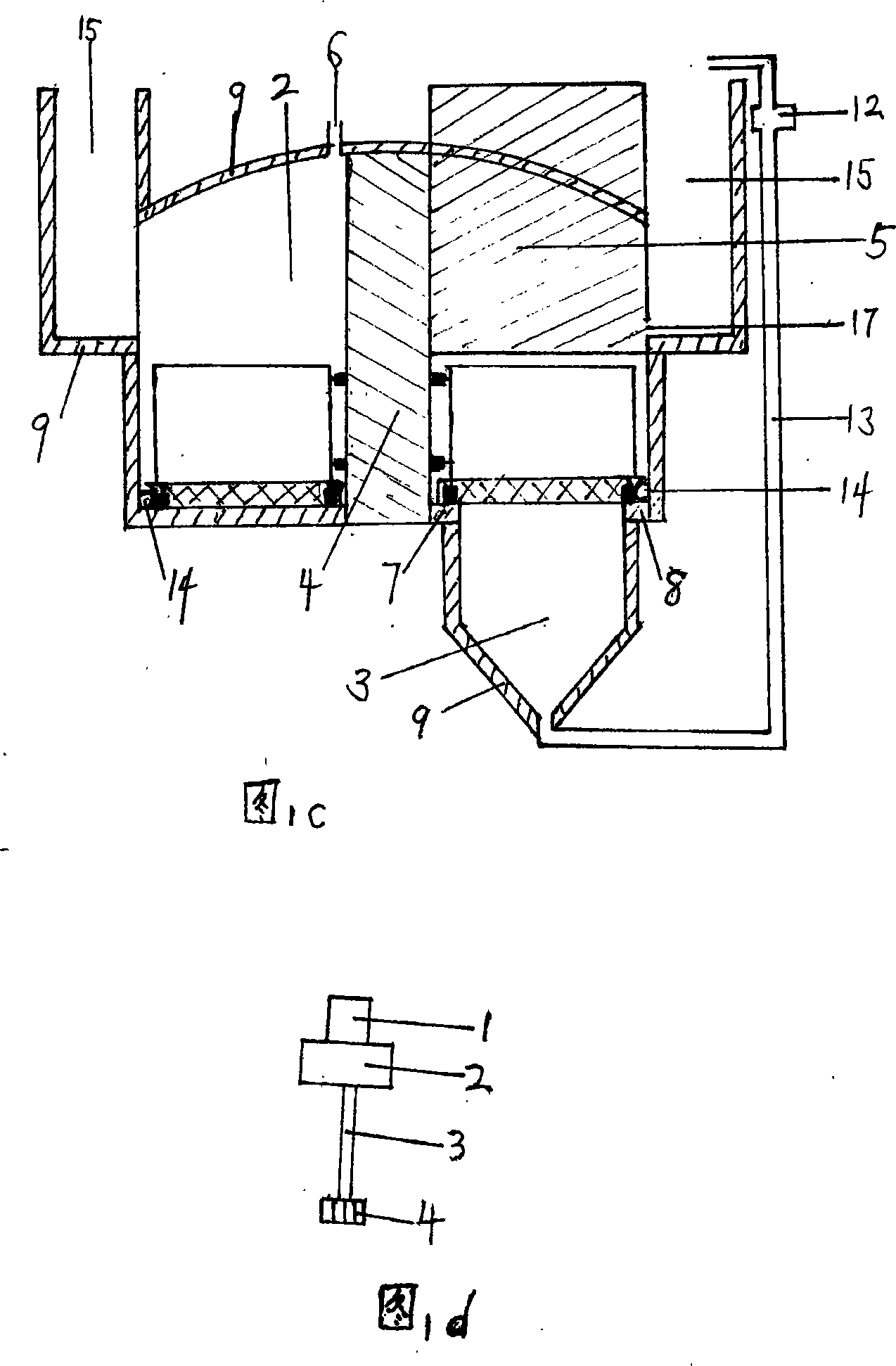

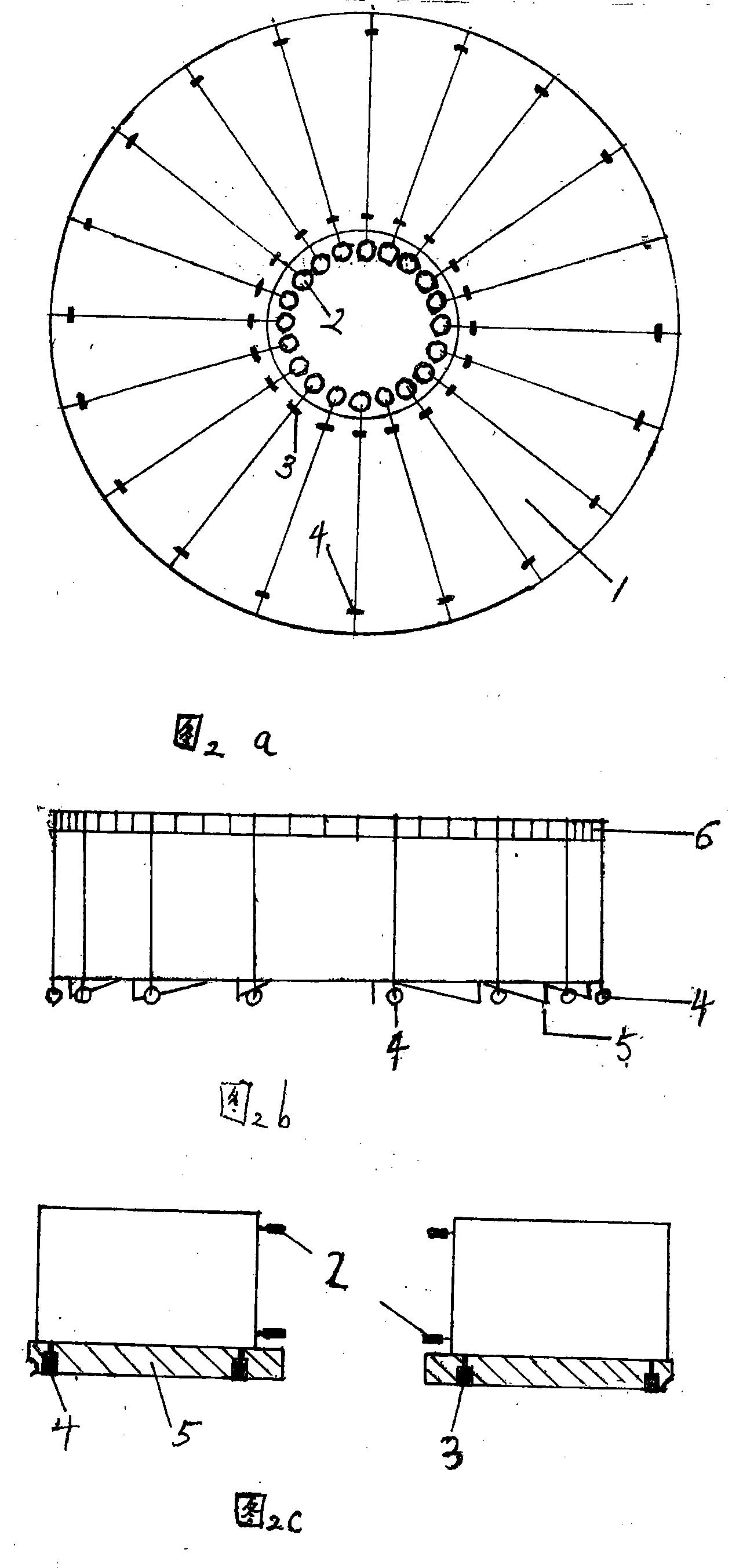

[0023] Concrete structure of the present invention: it is the circular biogas digester of reinforced concrete structure or (combined by N ring-shaped biogas digesters in the same ring) annular biogas digester group, annular feed bin group, material box, chassis drive machine, It is composed of a mud pump, a hydraulic liquid adjustment tank and a slag liquid separation tank.

[0024] 1. Circular biogas pool

[0025] like figure 1 a. figure 1 b. figure 1 As shown in c, the circular biogas digester of the present invention consists of an inlet and outlet room 1, a gas production and gas storage room 2, a biogas residue sedimentation pool 3, a center pillar 4, a partition wall 5, an air outlet pipe 6, and the storage room chassis of the inlet and outlet room. Circular track 7, Outer circular track 8 of the silo chassis between inlet and outlet, insulation layer 9, arc cover top 10, chassis driver 11 for the biogas digester, mud pump 12, sewage pipe 13, temperature regulating pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com