Construction method for temporarily supporting and strengthening reinforced concrete structured beam by using steel column

A reinforced concrete and temporary support technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of large consumption of support materials, dense arrangement of support poles, and increased load bearing of local beam sections. Achieve the effect of simple installation and removal, simple and practical operation, and low support materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

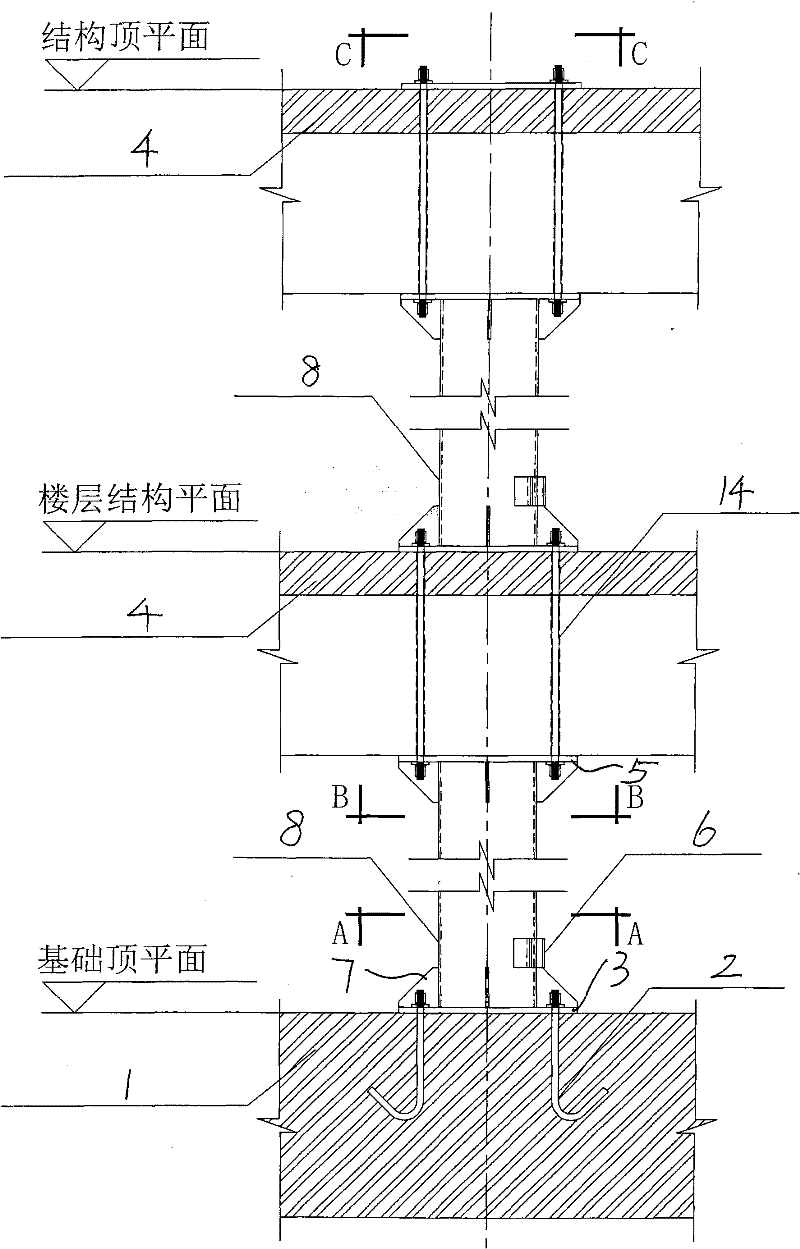

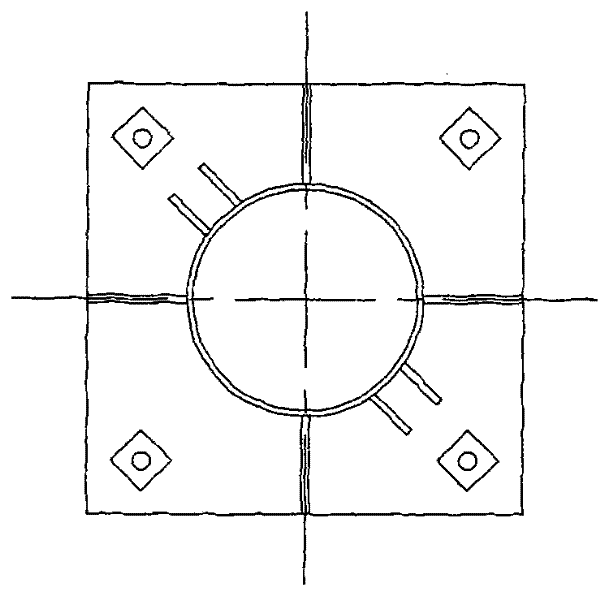

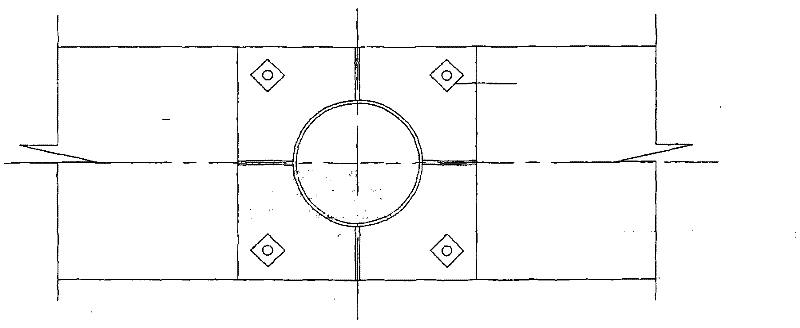

[0025] A construction method for temporarily supporting reinforced concrete structural beams with steel columns, comprising the following steps:

[0026] 1) During the construction of the concrete foundation, the threaded steel anchor bolt 2 with a straight thread head is embedded in the reinforced concrete foundation structure 1, or the threaded steel anchor bolt with a straight thread head is arranged after the reinforcement is planted; Threaded reinforcement bolt sleeves 14 with straight thread heads, or post-drilled holes for threaded steel bolts with straight thread heads;

[0027] 2) Check the flatness of the foundation plane, beam bottom plane and beam top plane of the steel column to be supported, use a trowel to polish the surface of the support base, and process the steel column and the thread with a straight thread head according to the construction design requirements Steel bolts, supporting sleeves;

[0028] 3) Place the steel column base plate 3, use one or two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com