Broken wire on-load processing device for low-voltage distribution insulated conductor and processing method thereof

A technology of insulated wires and low-voltage power distribution, which is applied to cable installation devices, cable installation, electrical components, etc. It can solve problems such as irreparable losses, product quality, raw material loss, and difficult layout, and achieve good economic and social benefits. , Improving the efficiency of emergency repairs and reducing the scope of power outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

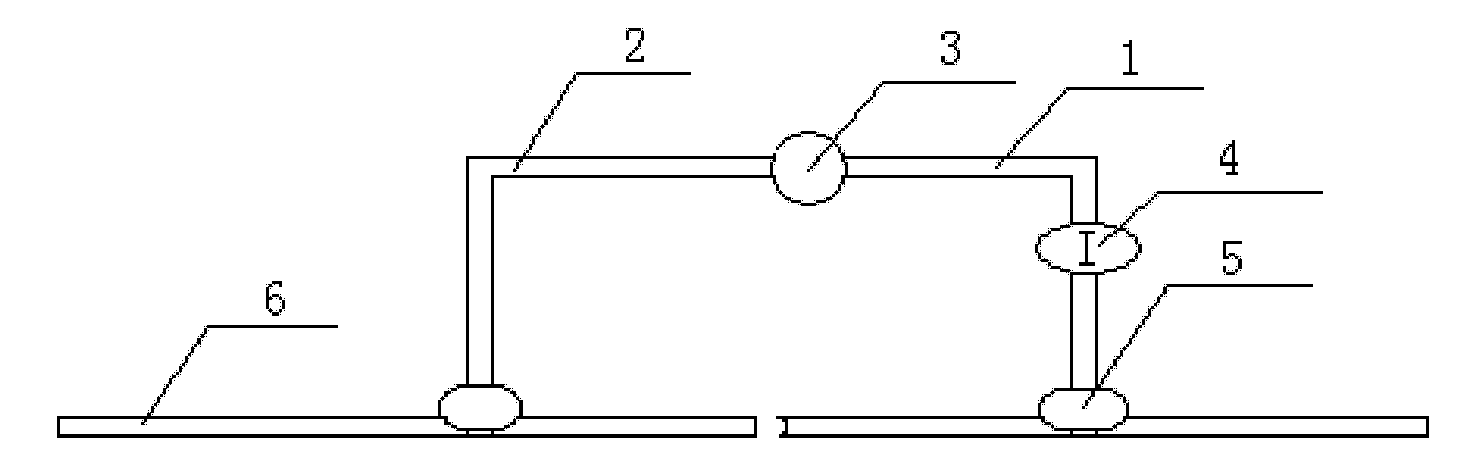

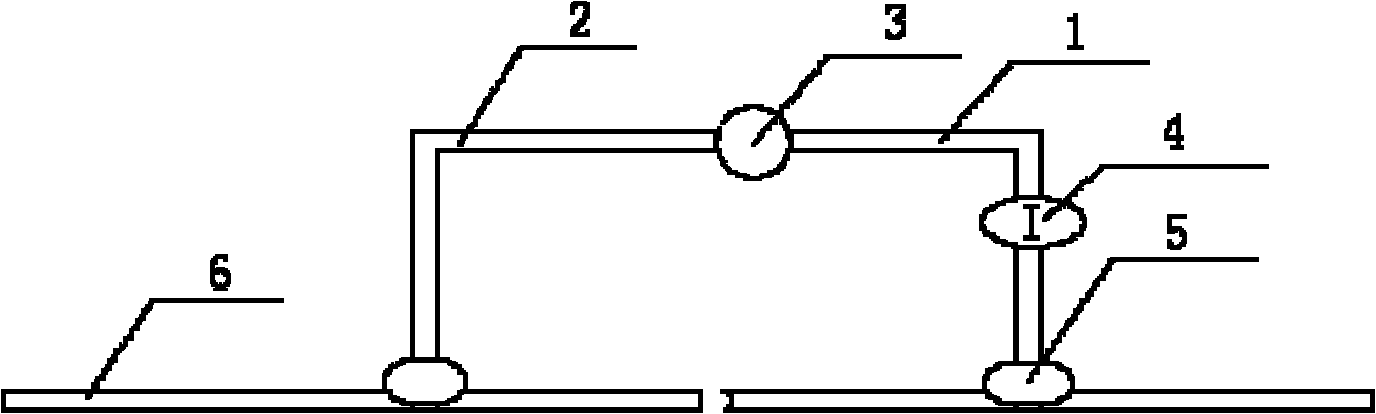

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail: see figure 1 , one Disclosed is a low-voltage power distribution insulated wire disconnection load processing device and a processing method thereof. The processing device and the processing method are simple, reliable, high in safety performance, convenient to use, and have good economic and social benefits.

[0016] The object of the present invention is solved by the following technical solutions: low-voltage power distribution insulated wire disconnection load processing device, the processing device is composed of insulation piercing clamp, first insulated cable, second insulated cable, low-voltage air circuit breaker The first insulated cable and the second insulated cable are connected through a low-voltage air circuit breaker; the first insulated cable is provided with a clamp ammeter; the first insulated cable and the second insulated cable The ends of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com