Micromechanical system

A micromechanical system and micromechanical technology, applied in the field of micromechanical systems, can solve problems such as increased cost and increased consumption of micromechanical systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

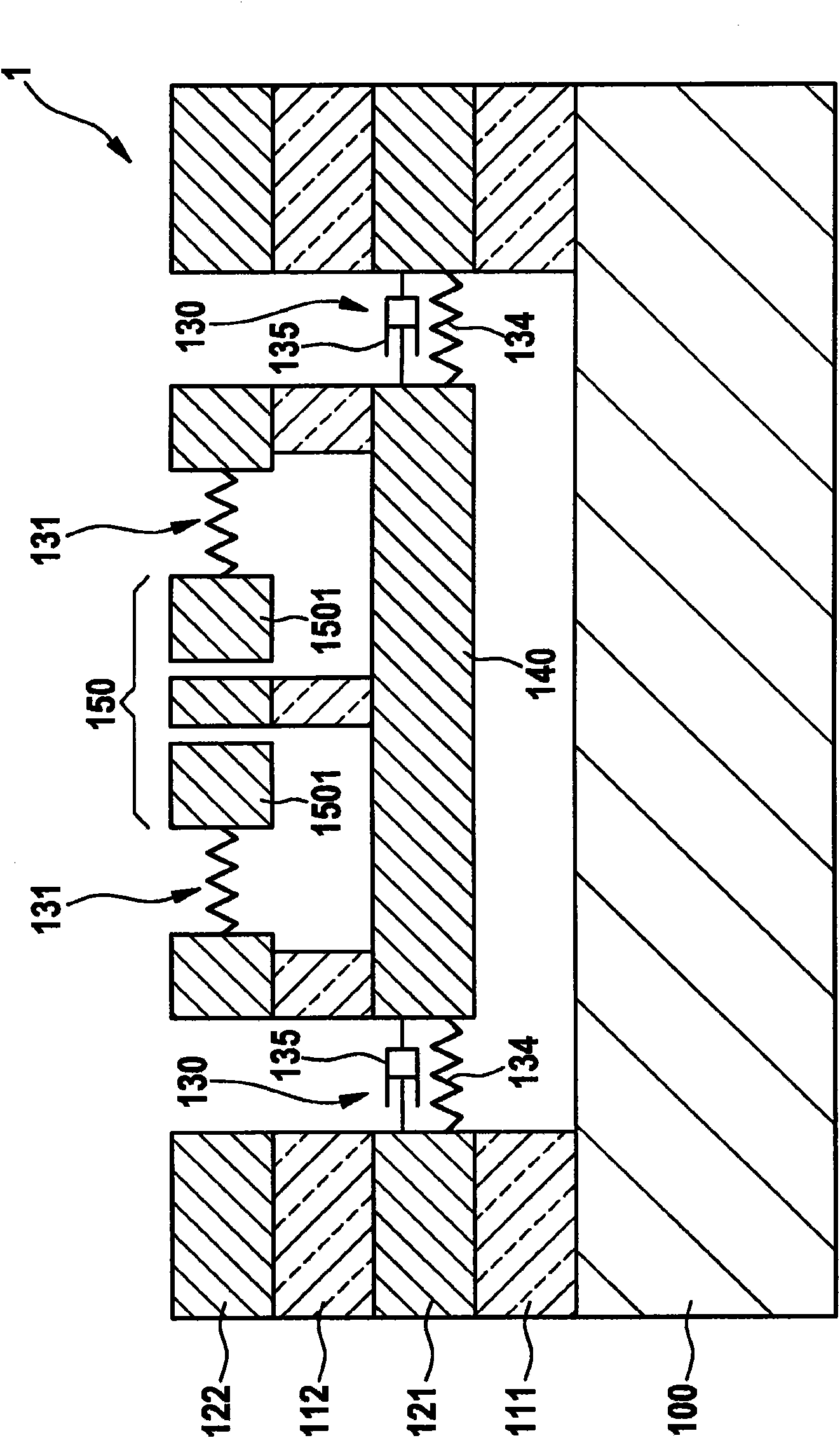

[0014] Figure 1A The micromechanical system according to the first embodiment of the invention is shown in a schematic side view along a cross section. The first micromechanical system 1 is here produced in a layered stack on the substrate 100 . The layered stack comprises a first consumable layer 111 , a first functional layer 121 , a second consumable layer 112 and a second functional layer 122 . The substrate 100 may include a semiconductor substrate, such as a silicon substrate, wherein the first and second consumable layers 111, 112 may include semiconductor oxides, such as silicon dioxide, and wherein the first and second functional layers 121, 122 may include Semiconductors, such as silicon. Furthermore, the semiconductor of the first and second functional layers 121, 122 may include silicon, polysilicon, amorphous silicon and / or epitaxially grown polysilicon (EPI). Such micromechanical systems, such as the first micromechanical system 1 , can be produced by sacrific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com