Ground sesame seed oil fine filtering method

A technology of small grinding of sesame oil and fine filtration, applied in the production/processing of edible oil/fat, etc., to achieve the effects of large output, low impurity content and short fine filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

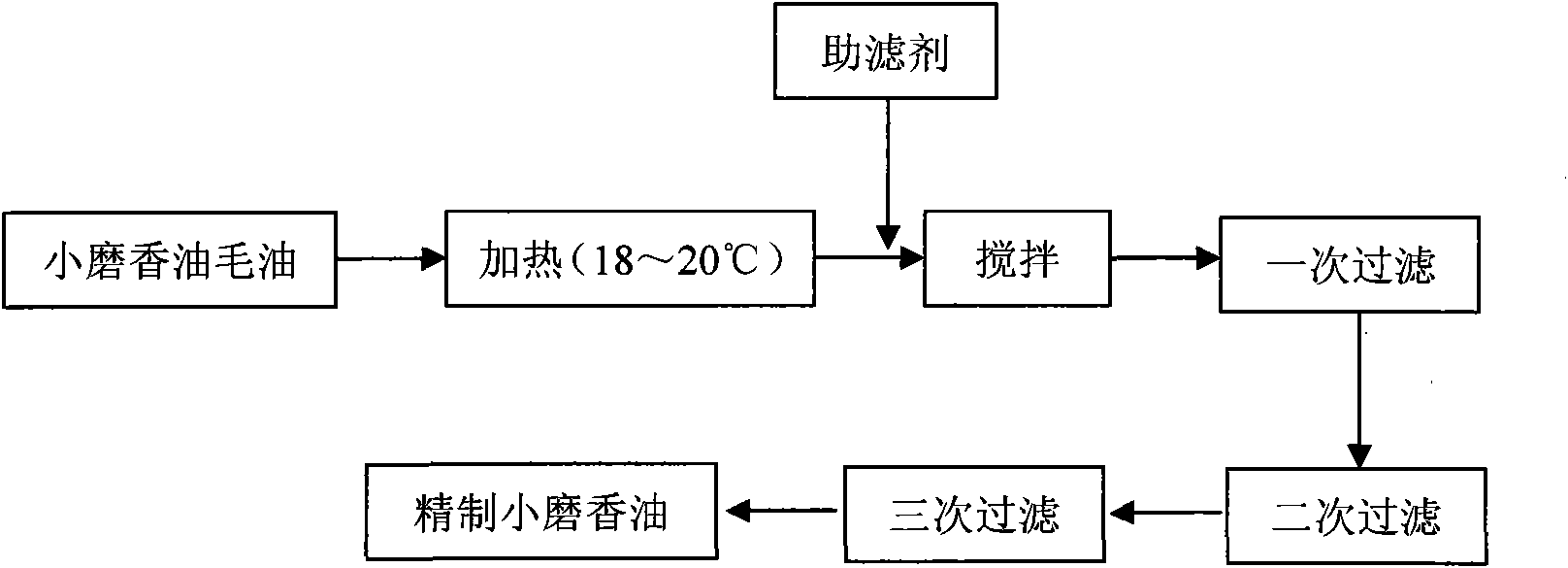

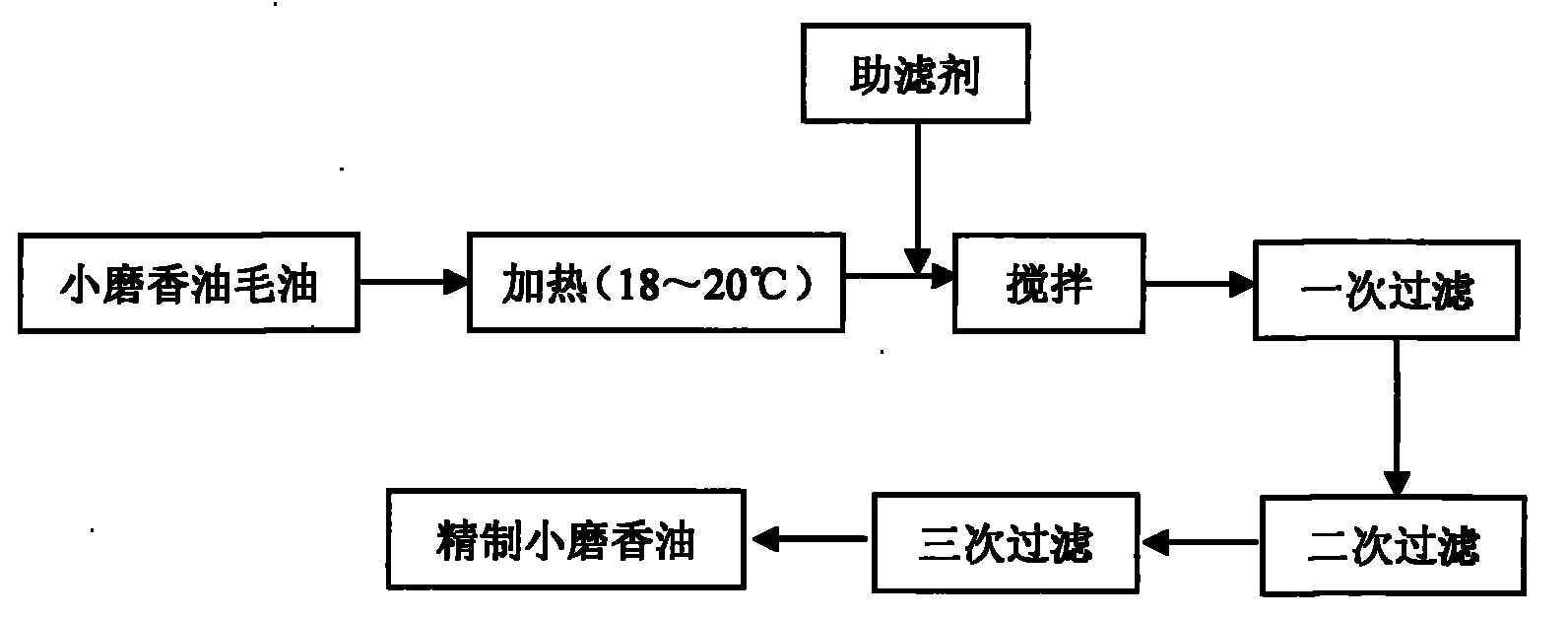

Method used

Image

Examples

example 1

[0024] Heat 1000kg of crude oil in the crude oil tank to 20°C, add 100kg of natural filter aid, stir evenly, and then send it to the vibrating slag filter through the gear pump for filtration to remove large impurity particles and part of the water.

[0025] After the primary filtration, the clear oil is sent to the natural sedimentation filter. A natural plant fiber material is used as the filter screen. The thickness of the fiber material is 15cm. Under the action of the oil's own weight, it naturally settles to remove most small particles and A little moisture.

[0026] The clean oil after secondary filtration is pumped into the cloth bag filter with a pipeline pump, and most of the fine impurities are removed by filtration, and the clean oil directly enters the finished oil tank after filtration. After filtration, the clear oil is clear and transparent, with low moisture and impurity content, stable product quality and long shelf life.

example 2

[0028] Heat 1500kg of crude oil in the crude oil tank to 18°C, add 200kg of natural filter aid, stir evenly, and then send it to the vibrating slag filter through the gear pump for filtration to remove large impurity particles and part of the water.

[0029] After primary filtration, the clear oil is transported to the natural sedimentation filter. A natural plant fiber material is used as the filter screen. The thickness of the fiber material is 20cm. A little moisture.

[0030] The clean oil after secondary filtration is pumped into the cloth bag filter with a pipeline pump, and most of the fine impurities are removed by filtration, and the clean oil directly enters the finished oil tank after filtration. After filtration, the clear oil is clear and transparent, with low moisture and impurity content, stable product quality and long shelf life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com