Structure for preventing continuous casting tundish from producing rotational flows

A continuous casting tundish and tundish technology, which is applied to casting equipment, casting melt containers, metal processing equipment and other directions, can solve the problems such as the inability to guarantee the improvement of the metal yield of inclusion control and the loss of molten metal, etc. Achieve the effect of eliminating molten steel slag, low manufacturing cost and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

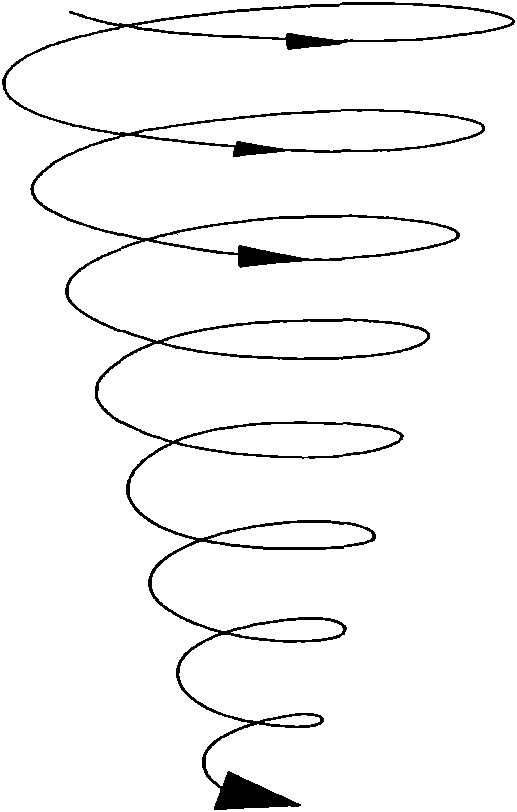

[0021] How to ensure that in the abnormal pouring state, by controlling the flow state of the molten metal near the upper nozzle of the tundish to control the generation of the vortex, and finally to control the slag of the molten metal and improve the yield of the molten metal, is the core of the patent of the present invention Purpose.

[0022] The present invention will be further described below in conjunction with accompanying drawing.

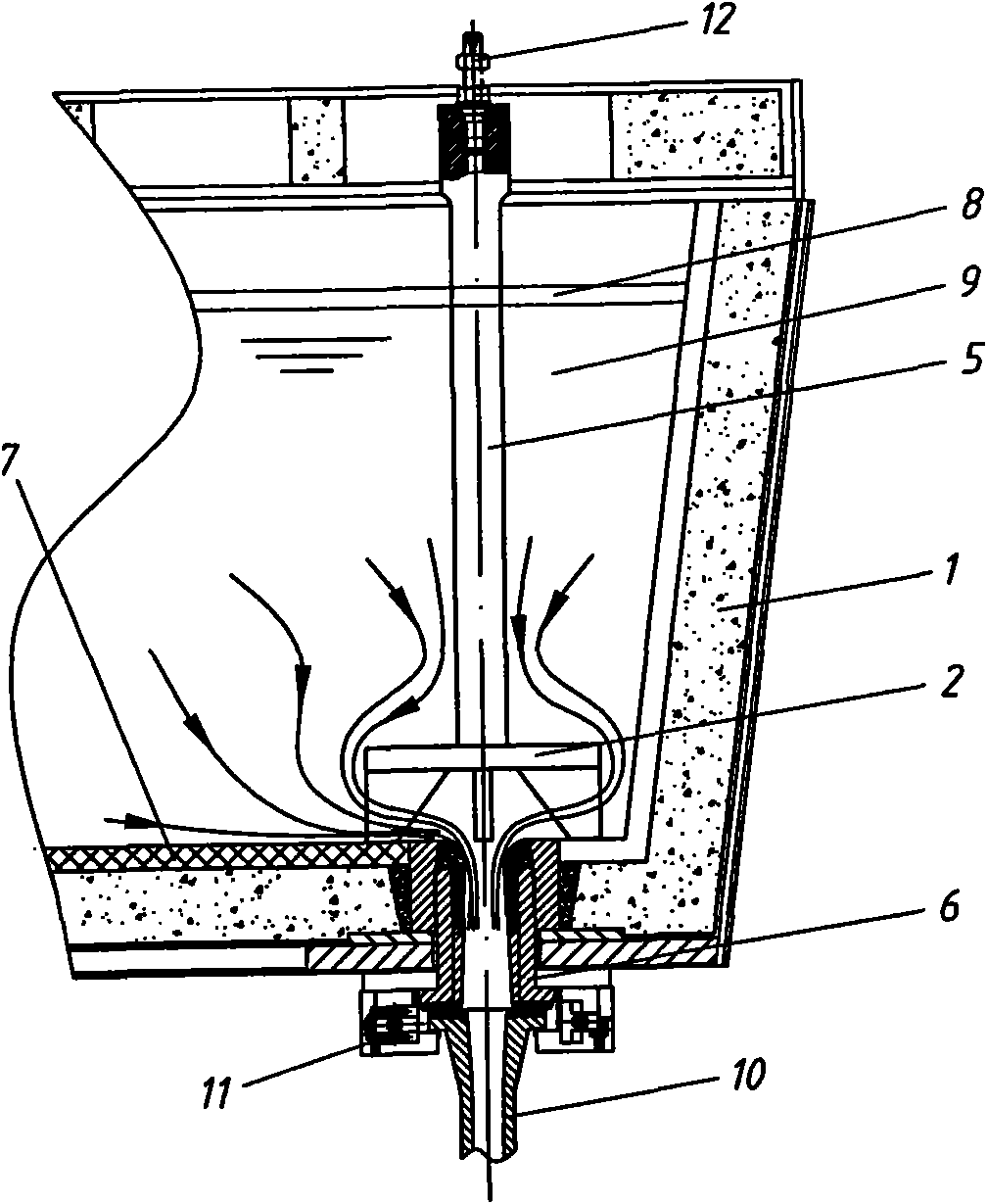

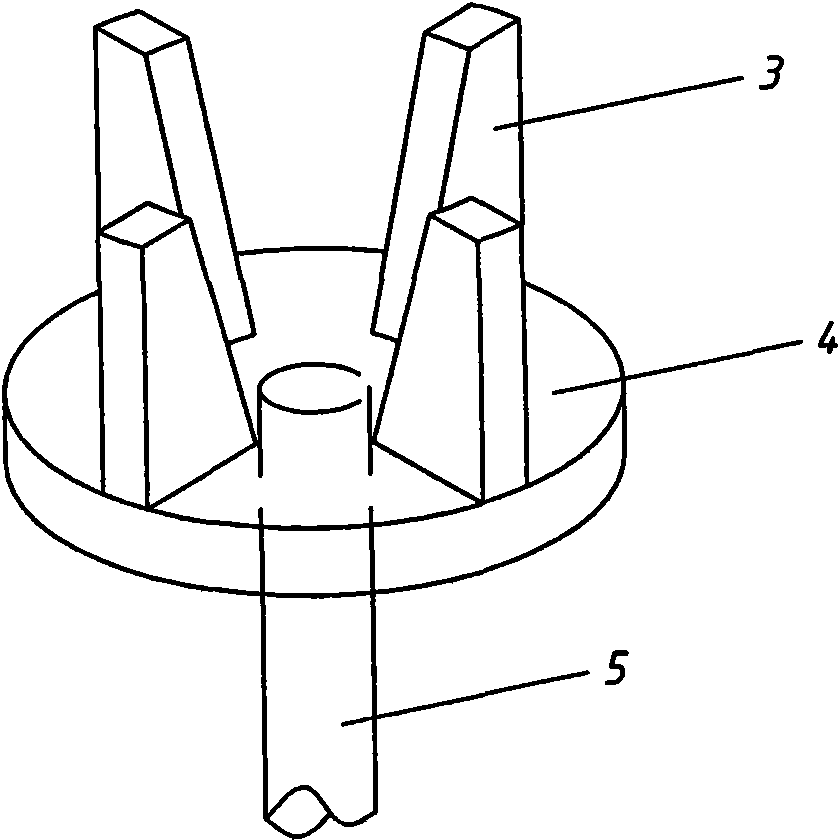

[0023] see figure 2 , as can be seen from the figure, the present invention prevents the continuous casting tundish from swirling structure, and a swirl suppressor 2 made of refractory material is provided in the tundish 1 which can be lifted. see also image 3 , the swirl suppressor 2 is mainly composed of a deflector 3, a disc 4 and a lifting rod 5 for lifting, the disc 4 is horizontally located directly above the upper nozzle 6 in the tundish, and the deflector 3 is several pieces ( The figure shows four pieces), the deflector 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com