Kaolinite lamellar crystal and preparation method thereof

A flaky crystal and kaolinite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of few studies on the exfoliation of coal-measure kaolin, and achieve significant social and environmental benefits, Solve the effect of insufficient resource reserves and good crystal shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

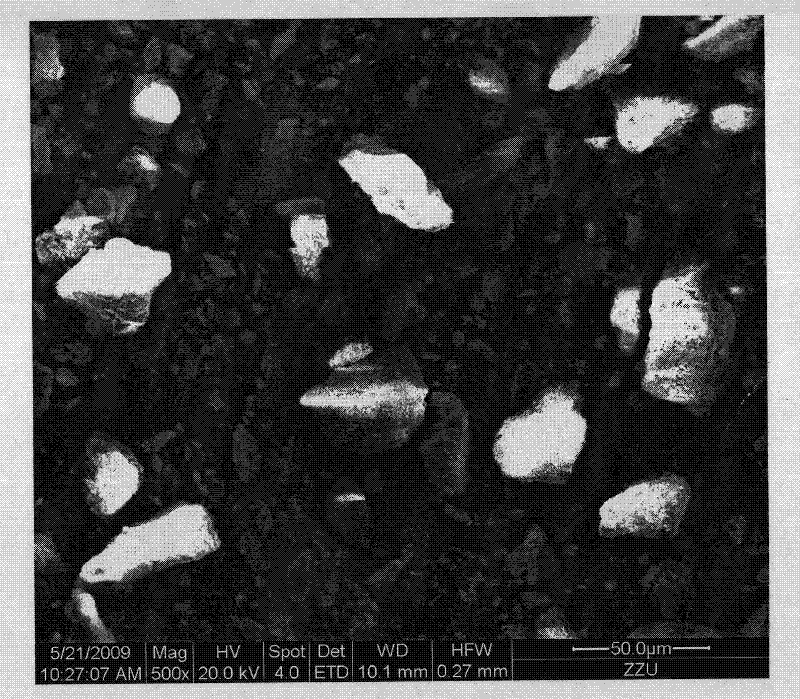

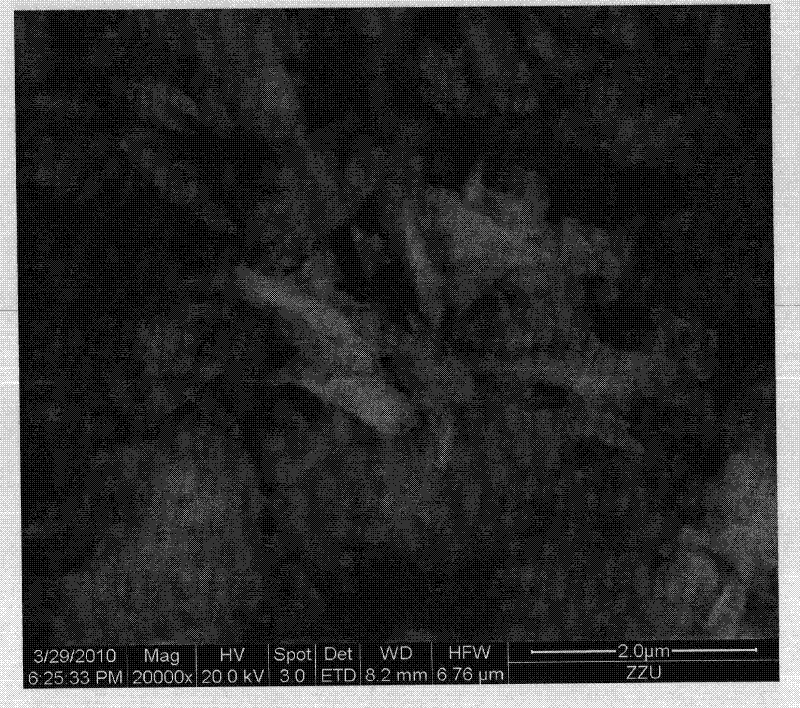

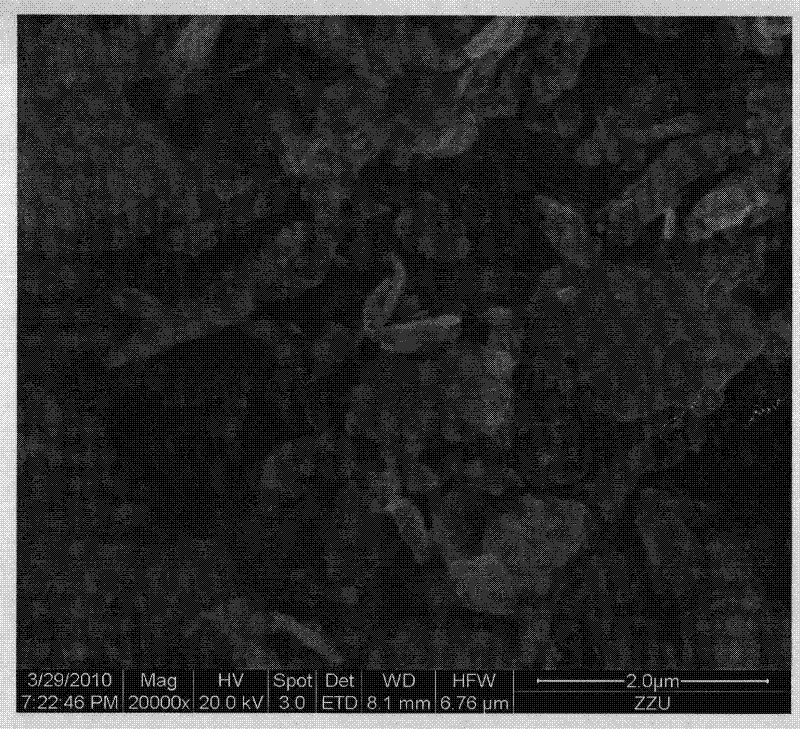

[0027] The preparation method is as follows: (1) mechanically pulverize coal series kaolin until the particle size is less than 43 microns; (2) prepare a mixed solution with distilled water and dimethyl sulfoxide (DMSO) at a volume ratio of 1:15, and then mix kaolin and DMSO The solution was mixed according to a mass ratio of 1:10, and after stirring continuously at 50°C for 4 hours, it was filtered with suction, and the obtained precipitate was washed with absolute ethanol, filtered with suction, and dried to obtain a kaolin / dimethyl sulfoxide intercalation complex. The intercalation rate is 90%; (3) After mixing the kaolin / dimethyl sulfoxide intercalation complex with the urea solution with a concentration of 11mol / L according to the mass ratio of 1:12, react at 20°C for 2h under stirring conditions , after suction filtration, distilled water washing, suction filtration and drying, the kaolin / urea intercalation compound was obtained, and the intercalation rate was 90%; (4) th...

Embodiment 2

[0029] The preparation method is as follows: (1) Mechanically pulverize the coal series hard kaolin until the particle size is less than 43 microns; (2) prepare a mixed solution with distilled water and dimethyl sulfoxide (DMSO) at a volume ratio of 1:8, and then mix the kaolin Mixed with DMSO solution at a mass ratio of 1:12, stirred continuously at 70°C for 48 hours, and then centrifuged. The resulting precipitate was washed with absolute ethanol, centrifuged, and dried to obtain a kaolin / dimethyl sulfoxide intercalation composite body, the intercalation rate is 94%; (3) After mixing the kaolin / dimethyl sulfoxide intercalation complex with the urea solution whose concentration is 13mol / L according to the mass ratio of 1:9, the After reacting for 48 hours, centrifuging, washing with absolute ethanol, centrifuging and drying, the kaolin / urea intercalation complex was prepared with an intercalation rate of 94%; (4) Grinding the kaolin / urea intercalation complex and zirconium sil...

Embodiment 3

[0031] The preparation method is as follows: (1) Mechanically pulverize the coal series hard kaolin until the particle size is less than 43 microns; (2) prepare a mixed solution with distilled water and dimethyl sulfoxide (DMSO) at a volume ratio of 1:10, and then mix the kaolin Mixed with DMSO solution at a mass ratio of 1:11, stirred continuously at 60°C for 24 hours, and then centrifuged. The resulting precipitate was washed with absolute ethanol, centrifuged, and dried to obtain a kaolin / dimethyl sulfoxide intercalation composite body, the intercalation rate is 98%; (3) After mixing the kaolin / dimethyl sulfoxide intercalation complex with the urea solution whose concentration is 12mol / L according to the mass ratio of 1:10, the After reacting for 1 hour, centrifuging, washing with absolute ethanol, centrifuging and drying, the kaolin / urea intercalation complex was prepared, with an intercalation rate of 97%; (4) Grinding the kaolin / urea intercalation complex and zirconium si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com