Method for obtaining whole martensite welding part of coated manganese-boron steel plate

A technology for welding parts and martensite, applied in welding media, welding equipment, welding equipment, etc., can solve the problems of high cost, high energy consumption, low production efficiency, etc., achieve good mechanical properties, reduce processing costs, and improve work. Efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

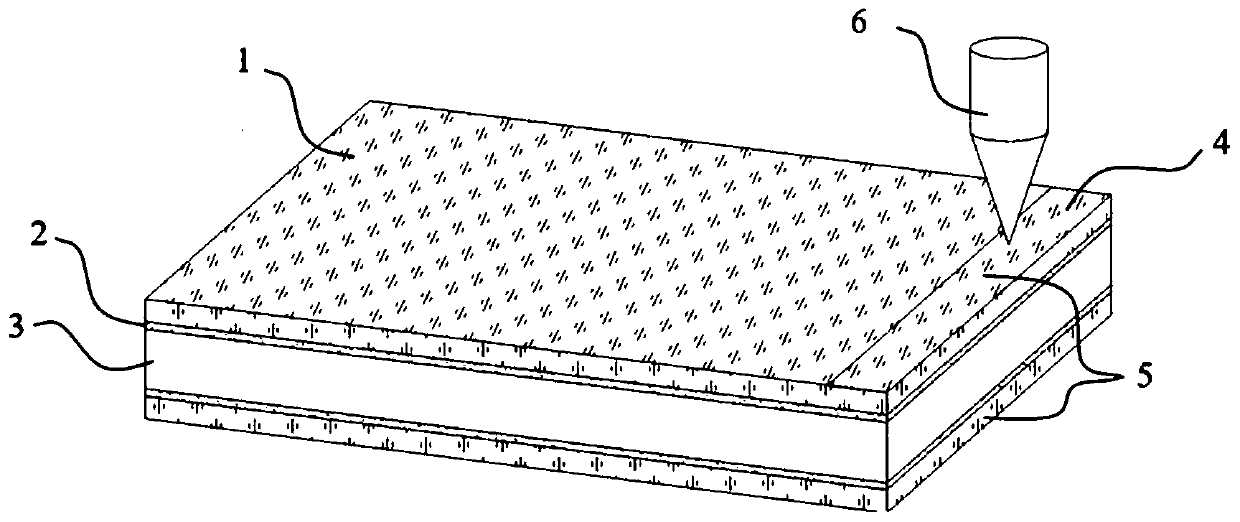

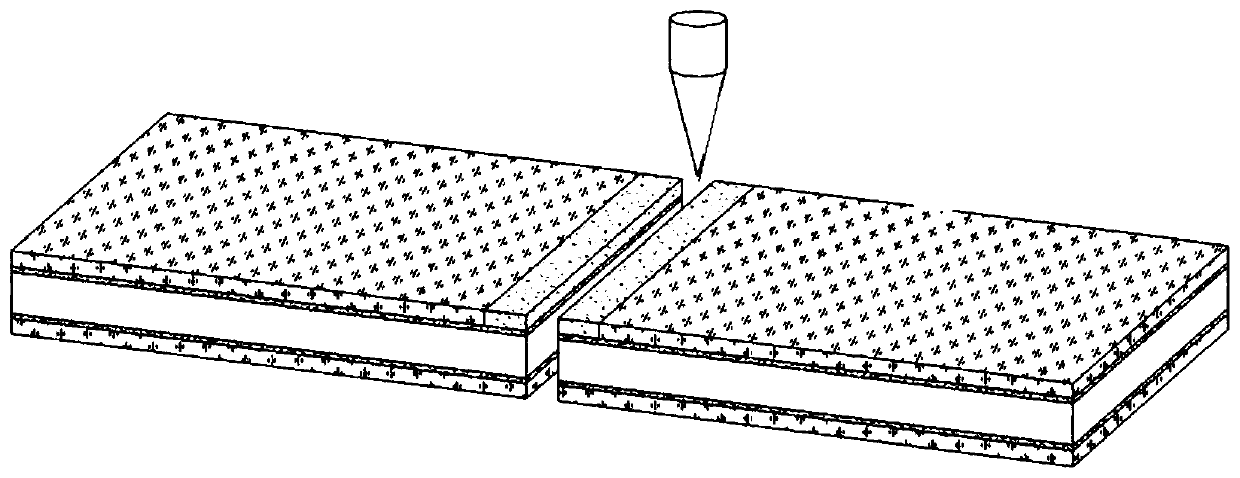

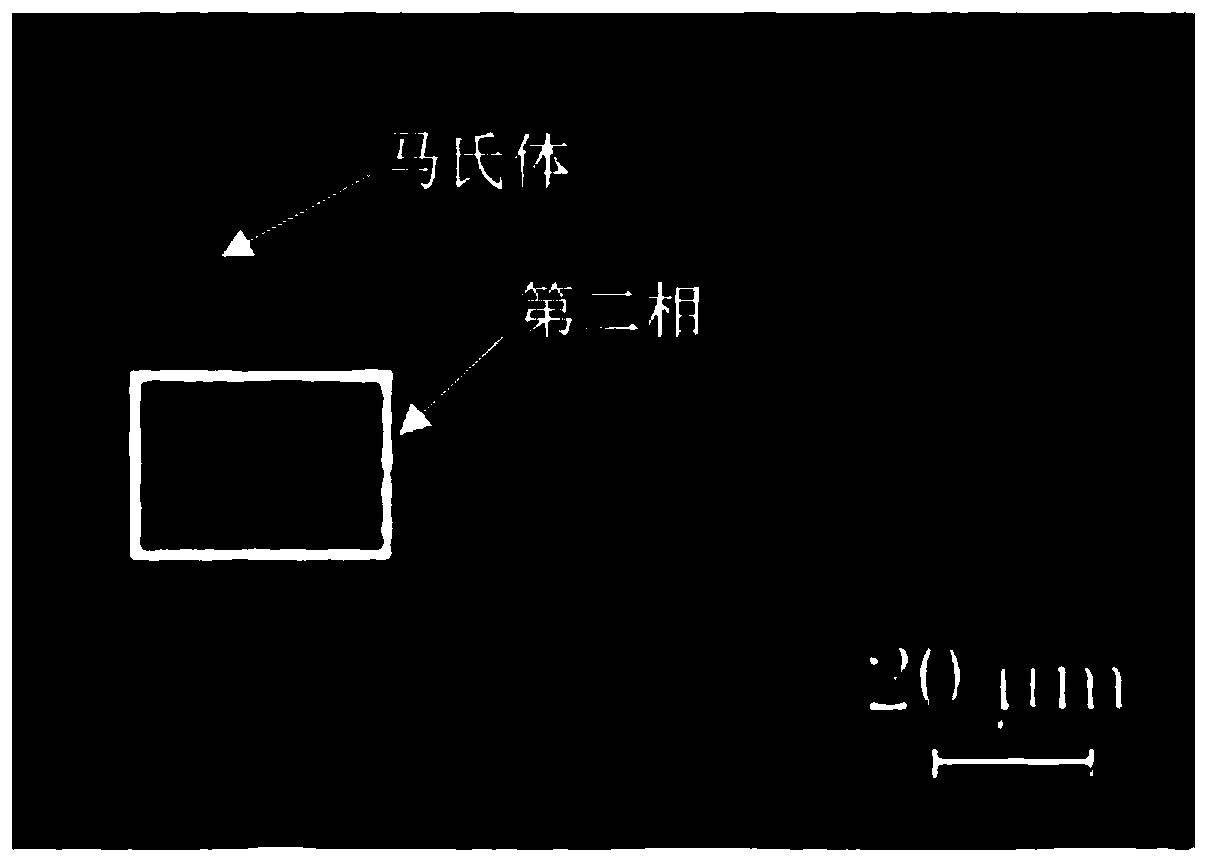

[0035] Such as figure 1As shown, the aluminum-silicon-coated manganese-boron steel sheet involved in the present invention consists of a manganese-boron steel sheet substrate 3 and a coating, wherein the coating consists of an aluminum-silicon alloy layer 1 placed on the outer layer and an aluminum-iron intermetallic compound layer 2 placed on the inner layer Composition, the thickness of the aluminum-silicon alloy layer 1 is 20 μm, the thickness of the aluminum-iron intermetallic compound layer 2 is 3 μm, the thickness of the manganese-boron steel plate substrate 3 is 1.5 mm, the length is 500 mm, and the width is 200 mm. First select the area 5 to be welded, and use a rapid heat source 6 to form a stable temperature of 750 ° C in the in-situ modified area 4 of the surface coating of the area 5 to be welded, that is, within the width range of 2 to 3 mm from the edge of the manganese-boron steel plate substrate 3. For the temperature field, the length direction of the in-situ ...

Embodiment 2

[0040] In the aluminum-silicon-coated manganese-boron steel sheet involved in the present invention, the thickness of the aluminum-silicon alloy layer is 30 μm, the thickness of the aluminum-iron intermetallic compound layer is 10 μm, and the thickness of the manganese-boron steel sheet substrate is 2 mm. Using a high-frequency induction heating heat source to in-situ modify the surface coating within the width range of 1-2 mm from the edge of the manganese-boron steel plate, the temperature is heated to 850 ° C and kept for 5 minutes. During the heating and cooling process, the continuous flow rate is 20l / min nitrogen protection gas. Finally, the two coated manganese-boron steel plates after the in-situ surface modification above were butt welded by laser welding, the laser power was 4kw, the laser beam spot diameter was 0.6mm, the defocus amount was 0, and the welding speed was 6m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com