Preparation of asparagus rough polysaccharide and application thereof in cigarette

A technology of asparagus and crude polysaccharides, which is applied in the field of preparation of asparagus crude polysaccharides, to achieve the effects of improving the quality of sucking food and improving the poor moisture retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Asparagus after pre-treatments such as infrared enzyme inactivation, washing, impurity removal, and drying, bake in an oven at 60°C for 3 hours until the moisture content is below 10%, pass through a 40-mesh sieve after crushing, and add 3 times the weight of Water, heated and refluxed at 70°C for 2 hours, then subjected to high-speed centrifugation of the water extract, filtered the supernatant through gauze, concentrated the filtrate to 60% of the original volume, added 3 times the volume of 95% ethanol to the concentrated solution, and let it stand After 12 hours, filter through gauze, and dry the sediment to obtain the crude polysaccharide from asparagus.

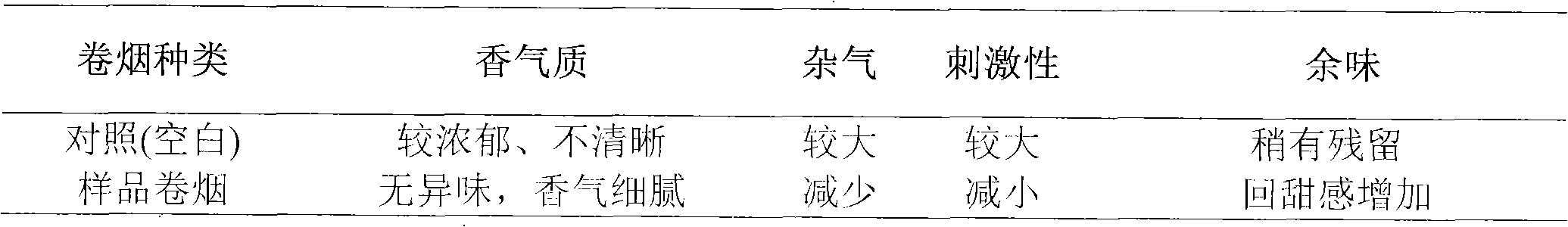

[0026] The asparagus crude polysaccharide is dissolved in water, sprayed evenly on the cut tobacco according to 0.001% of the weight of the shredded tobacco, and made into a cigarette. The results of smoking evaluation show that the smoke of the added cigarette has no peculiar smell, and the aroma of the cigarett...

Embodiment 2

[0028] Asparagus after pre-treatments such as infrared enzyme inactivation, washing, impurity removal, and drying, bake in an oven at 50°C for 5 hours until the moisture content is below 10%, pass through a 20-mesh sieve after crushing, and add 4 times the weight of Water, using 400w power, microwave-assisted reflux extraction for 5 minutes, then the water extract was subjected to high-speed centrifugation, the supernatant was filtered through gauze, the filtrate was concentrated to 70% of the original volume, and 4 times the volume of 95% ethanol was added to the concentrated solution. After standing still for 24 hours, filter through gauze, and dry the sediment to obtain the crude polysaccharide of asparagus.

[0029] The asparagus crude polysaccharide is dissolved in water, sprayed evenly on the cut tobacco according to 0.01% of the weight of the shredded tobacco, and made into a cigarette. The results of the smoking test show that the smoke has no peculiar smell, and the a...

Embodiment 3

[0031] Asparagus after pre-treatments such as infrared enzyme inactivation, washing, impurity removal, and drying, bake in an oven at 70°C for 2 hours until the moisture content is below 10%, pass through a 60-mesh sieve after crushing, and add 7 times the weight of Water, ultrasonic-assisted reflux extraction for 45 minutes, then the water extract was subjected to high-speed centrifugation, the supernatant was filtered through gauze, the filtrate was concentrated to 80% of the original volume, 5 times the volume of 95% ethanol was added to the concentrated solution, and after standing for 20 hours , filtered through gauze, and the sediment was dried to obtain the crude polysaccharide of asparagus.

[0032] The asparagus crude polysaccharide is dissolved in water, sprayed evenly on the cut tobacco according to 0.05% of the weight of the shredded tobacco, and made into a cigarette. The results of smoking evaluation show that the smoke has no peculiar smell, and the aroma qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com