Quantitative test method for quality of high speed railway bituminous mortar construction

A quantitative detection method, asphalt mortar technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, roads, measuring instruments, etc., can solve problems such as inability to monitor health, and achieve the effect of controlling the quality of perfusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further introduced below in conjunction with the detailed embodiments shown in the accompanying drawings.

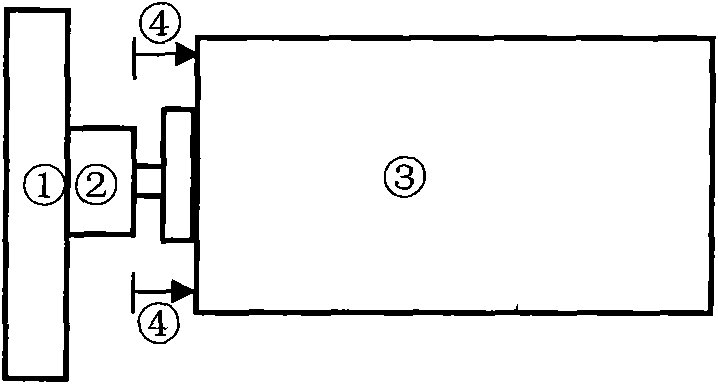

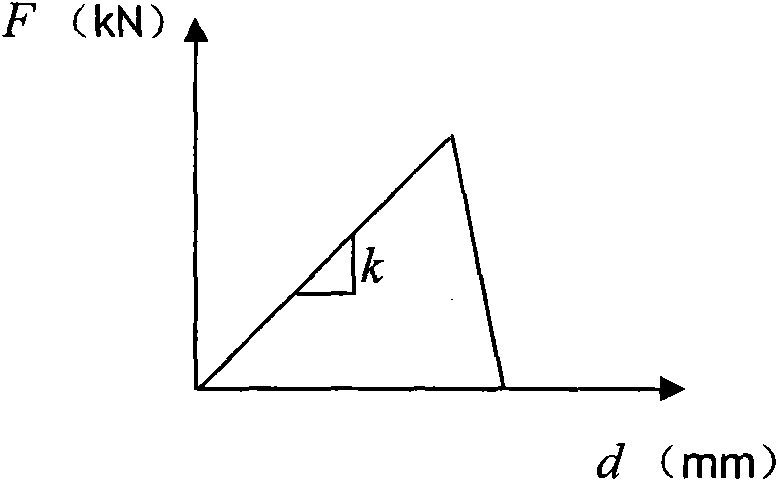

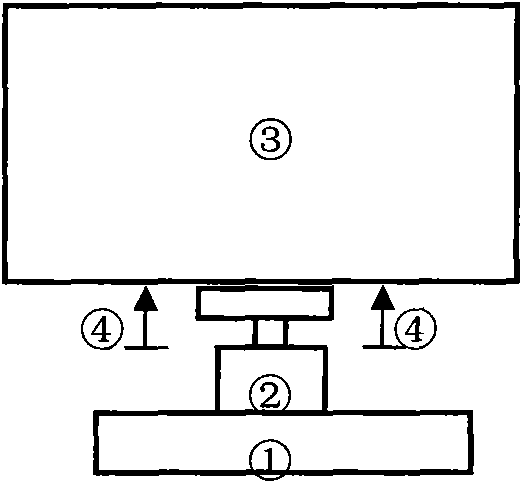

[0020] 1. Detection of bonding strength and bonding stiffness along the running direction

[0021] 1. Preset

[0022] (1) Set a concrete cap (1m×1m×1.5m) at the end of the slab, and reserve 4-6 riveting holes.

[0023] (2) Install the reaction frame on the concrete bearing platform through the reserved holes, and install the hydraulic jack on the reaction frame through bolts. During this installation process, it is necessary to ensure that the hydraulic jack is perpendicular to the loading surface of the track slab and the loading point is at At the midpoint of the track plate (loading side), paste a steel plate with a thickness of 1-2cm to prevent the track plate from being damaged due to local stress concentration during the loading process. The surface area of the steel plate should be slightly larger than the pressure head of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com