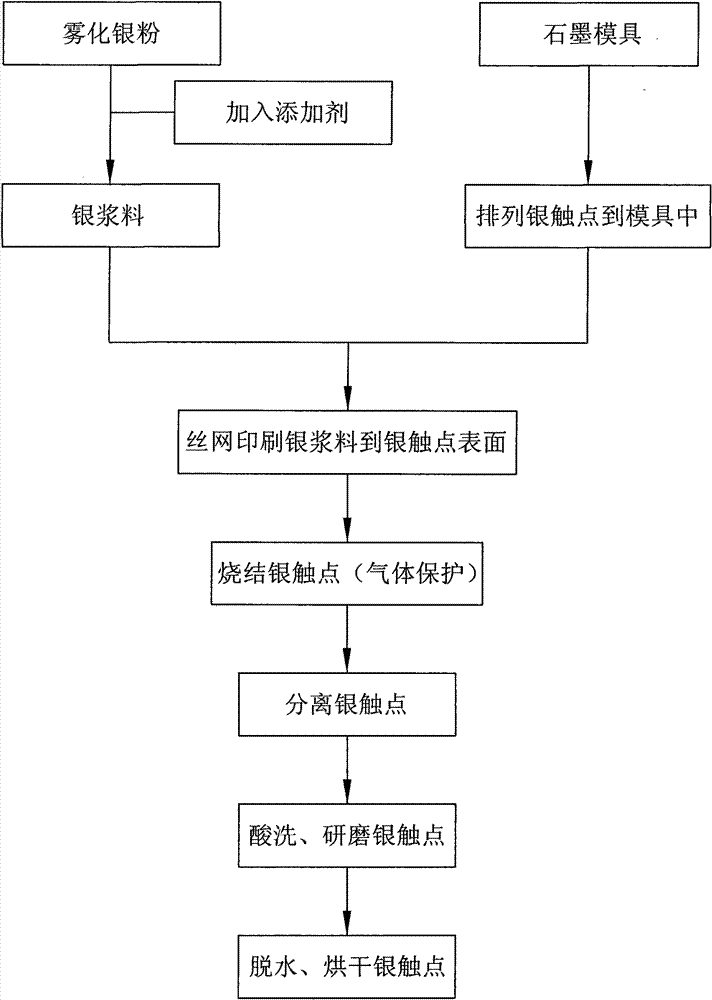

Method for fabricating contact silver-coated layer by screen printing

A technology of screen printing and silver layer, applied in printing, printing devices, electrical components and other directions, can solve the problems of hidden quality of contacts, complicated processes, affecting composite strength, etc., achieving good consistency, simple operation, and improved bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

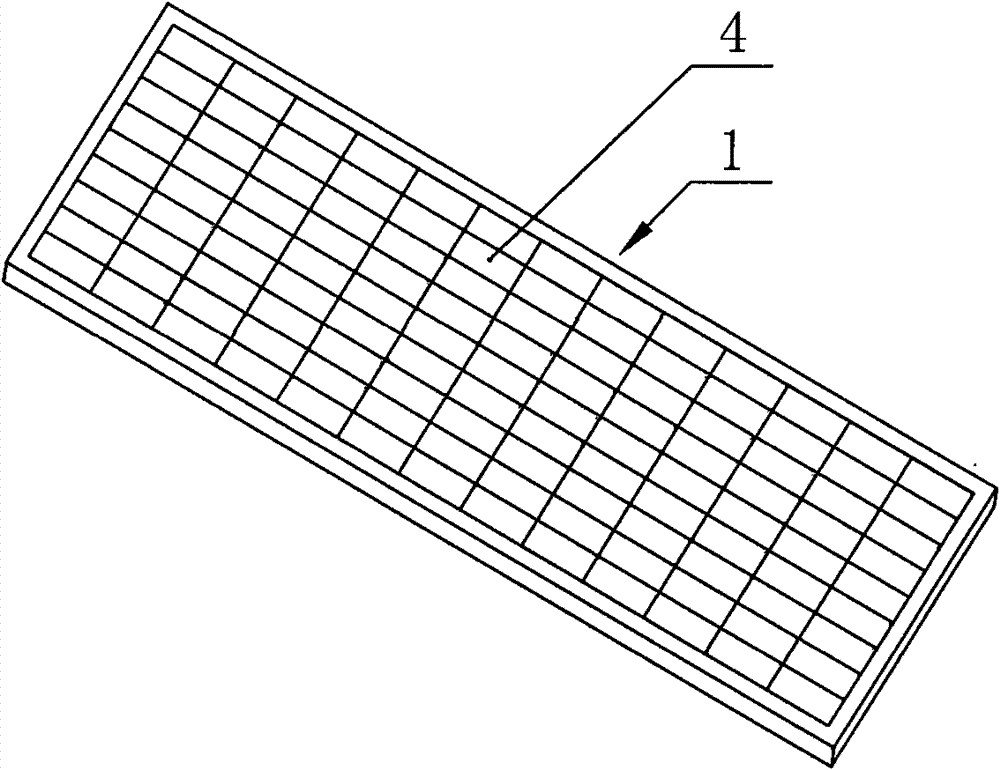

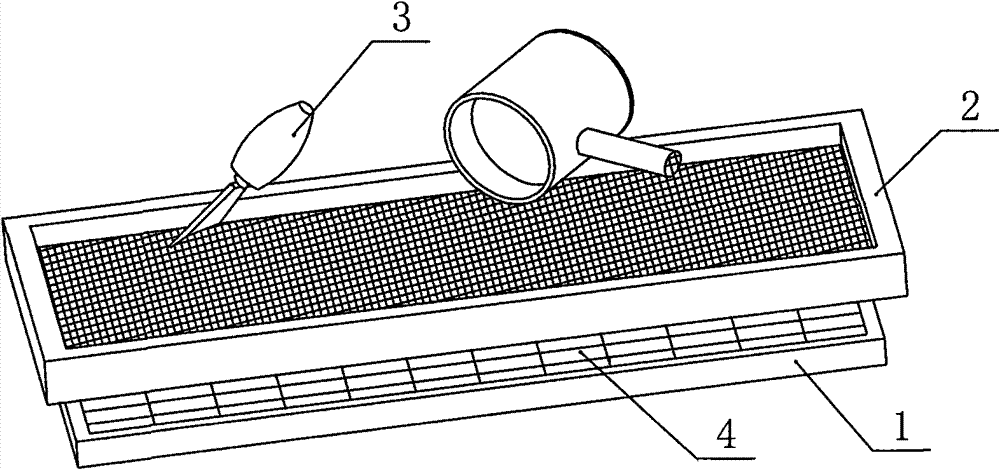

[0027] like Figure 1-4 As shown in the specific implementation of the present invention, the silver contact piece of this embodiment uses the contact piece of AgCdO12 as an example. Of course, the technical solution of the present invention can also be used to make a silver-coated layer on other silver alloy contact pieces.

[0028] (1) The contact piece of AgCdO12 is produced, without soldering silver layer, the size is 7.5×7.5×2; a total of 10 contacts;

[0029] (2) make atomized silver powder 1Kg, the silver powder average grain size is at 250 orders, certainly the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com