Method for drying a compressed gas

A technology for compressing gas and drying, which is applied in dryers to dry compressed gas and the drying field of compressed gas. It can solve problems such as high dew point pressure, prolonged heating steps, and unoptimized use of heating power, so as to improve reliability and shorten regeneration time. The effect of minimizing and reducing the number of dryers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

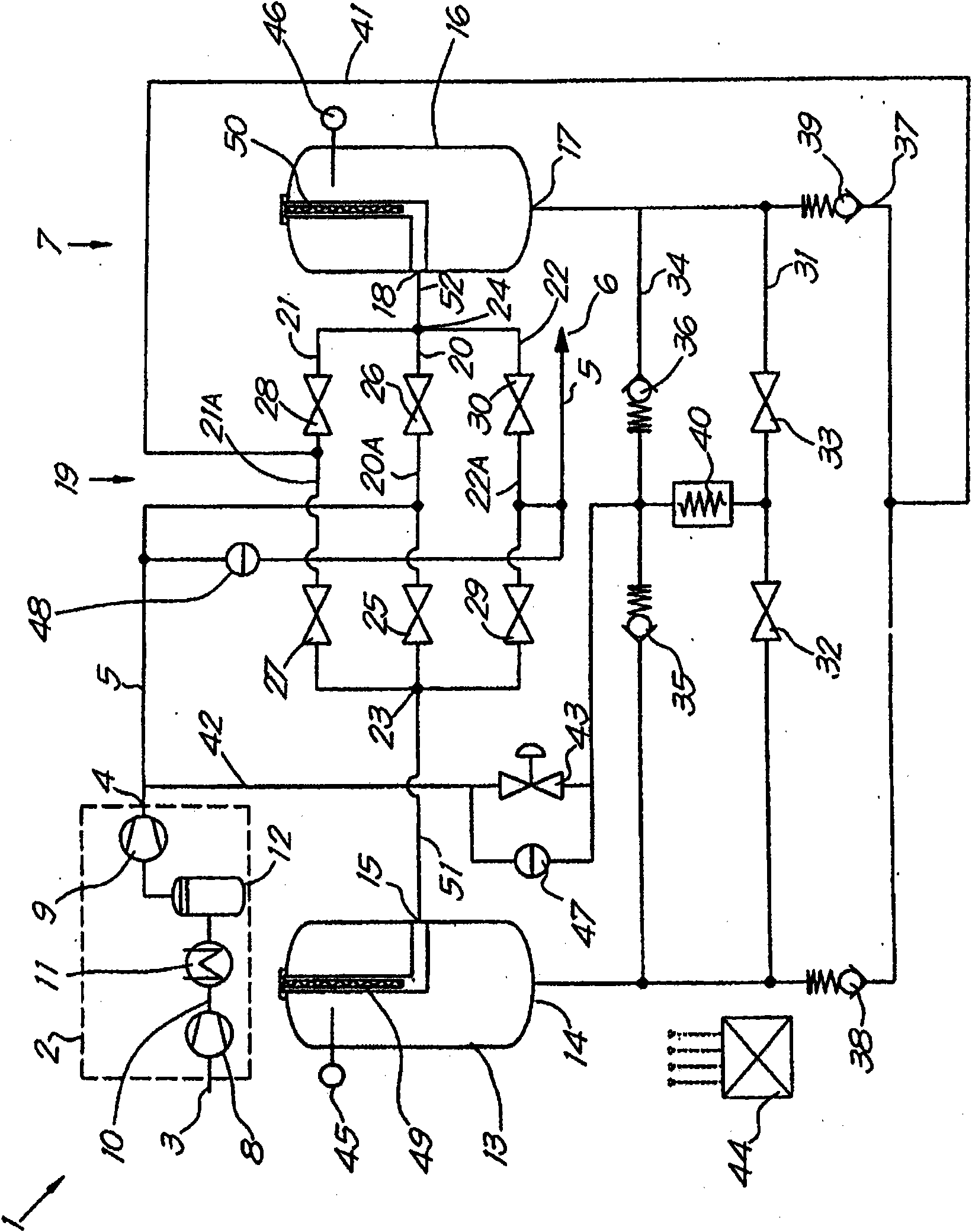

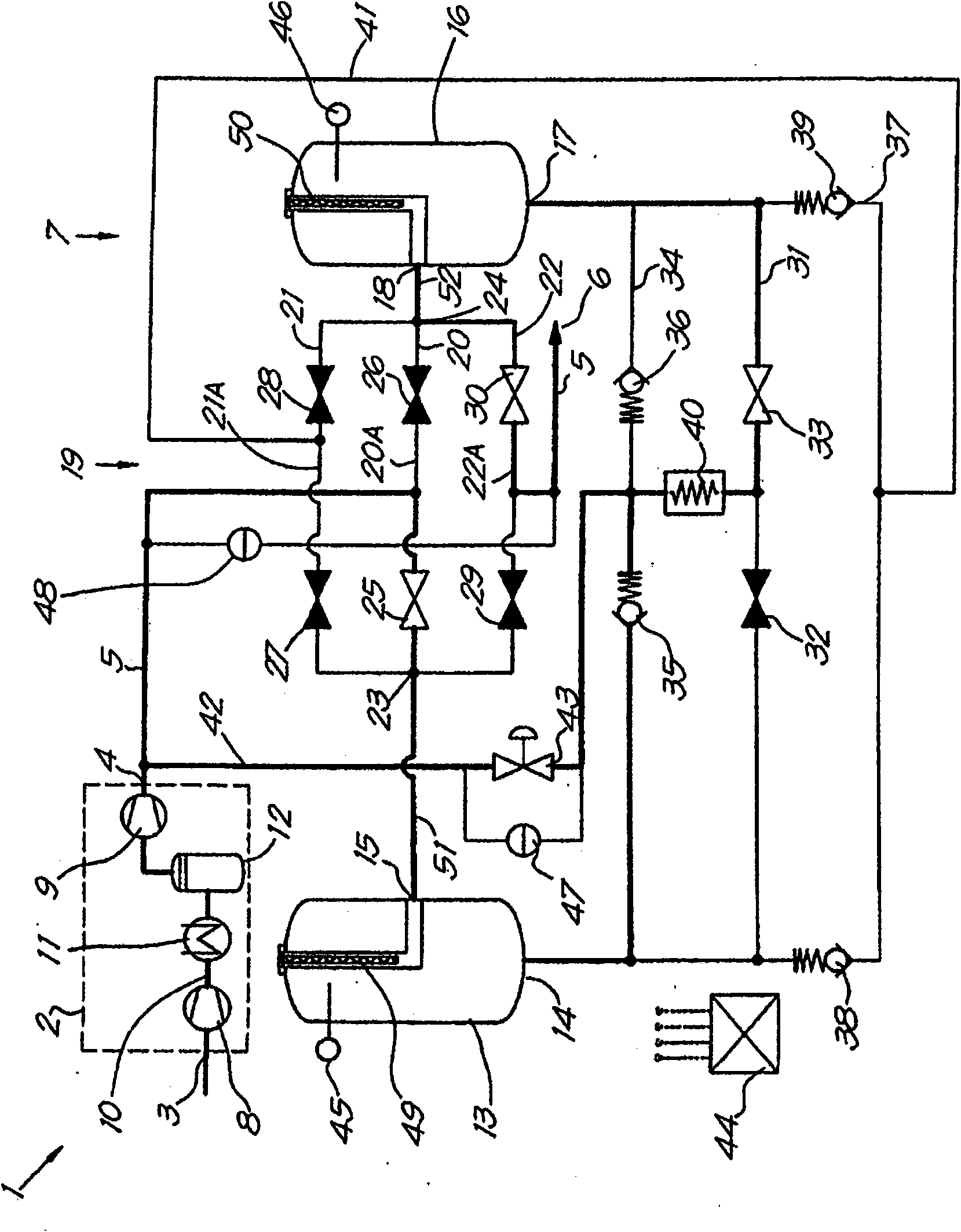

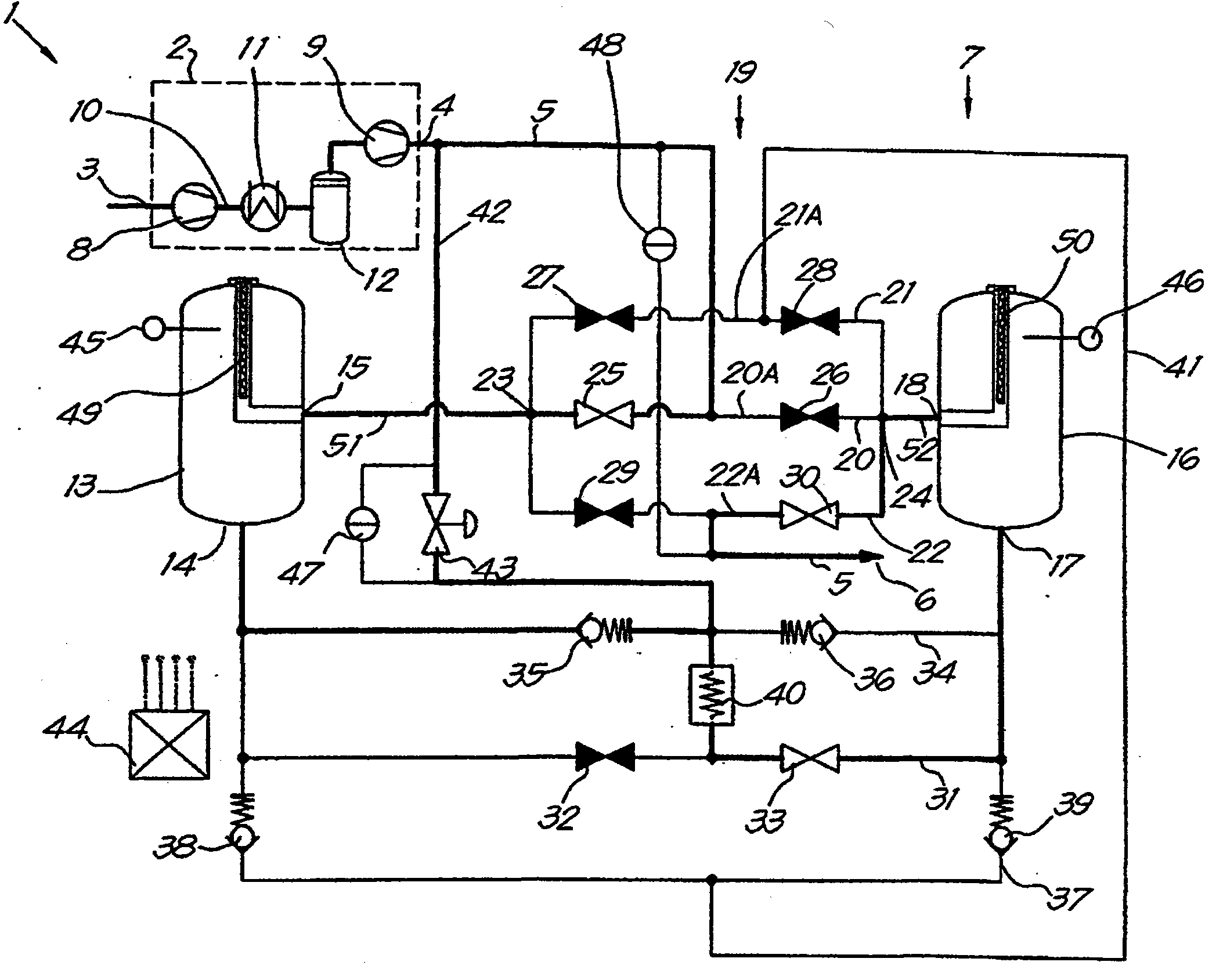

[0035] figure 1 Shown is a compressor device 1, which essentially comprises: a compressor 2 with an inlet 3 and an outlet 4; a compressed air line 5, which connects the outlet 4 of the compressor 2 to a user network 6; and a dryer 7, which combines In the above-mentioned compressed air pipeline 5.

[0036] In this example, the compressor 2 comprises a low-pressure section 8 and a high-pressure section 9 connected in series via a pressure line 10 in which an intercooler 11 and a water separator 12 are incorporated in succession.

[0037] The dryer 7 comprises: a first pressure vessel 13 with an inlet 14 and an outlet 15 containing silica gel or any other desiccant; a second pressure vessel 16 with an inlet 17 and an outlet 18 also containing a desiccant.

[0038] In addition, the drying machine 17 is provided with a distribution device 19, and the distribution device 19 includes three pipelines, which are respectively a first pipeline 20, a second pipeline 21 and a third pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com