High intensity asphalt modifier for cast asphalt concrete and preparation method thereof

A technology of asphalt modifier and asphalt concrete, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve problems such as rutting, affect the smoothness of the road surface, reduce the service life of the road surface, etc., and achieve strength and stiffness modulus Large, improve the anti-rutting ability, improve the effect of the force state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The distribution ratio of high-strength modified asphalt is as follows:

[0022] The component mass percentage is (%)

[0023] Zhonghai 70# Asphalt 82

[0024] High-strength asphalt modifier for pouring asphalt concrete 18

[0025] The composition ratio of high-strength asphalt modifier for castable asphalt concrete is as follows:

[0026] Component mass parts

[0027] Modifier 20 parts

[0028] Enhancer 15 parts

[0029] Viscosity reducer 55 parts

[0030] The modifier is a mixture of one or more of SBS, SIS, SBR, CR, etc., and the ratio between them is not required.

[0031] The reinforcing agent is a mixture of one or more of waste tire rubber powder, rock asphalt, lake asphalt, white carbon black, etc., and the ratio between them is not required.

[0032] Viscosity reducer is a mixture of one or more asphalt viscosity reducers such as Sasobit, SasobitLM, Eapave, and Saisu, and the ratio between them is not required.

[0033] According to the above raw material ratio, the following p...

Embodiment 1

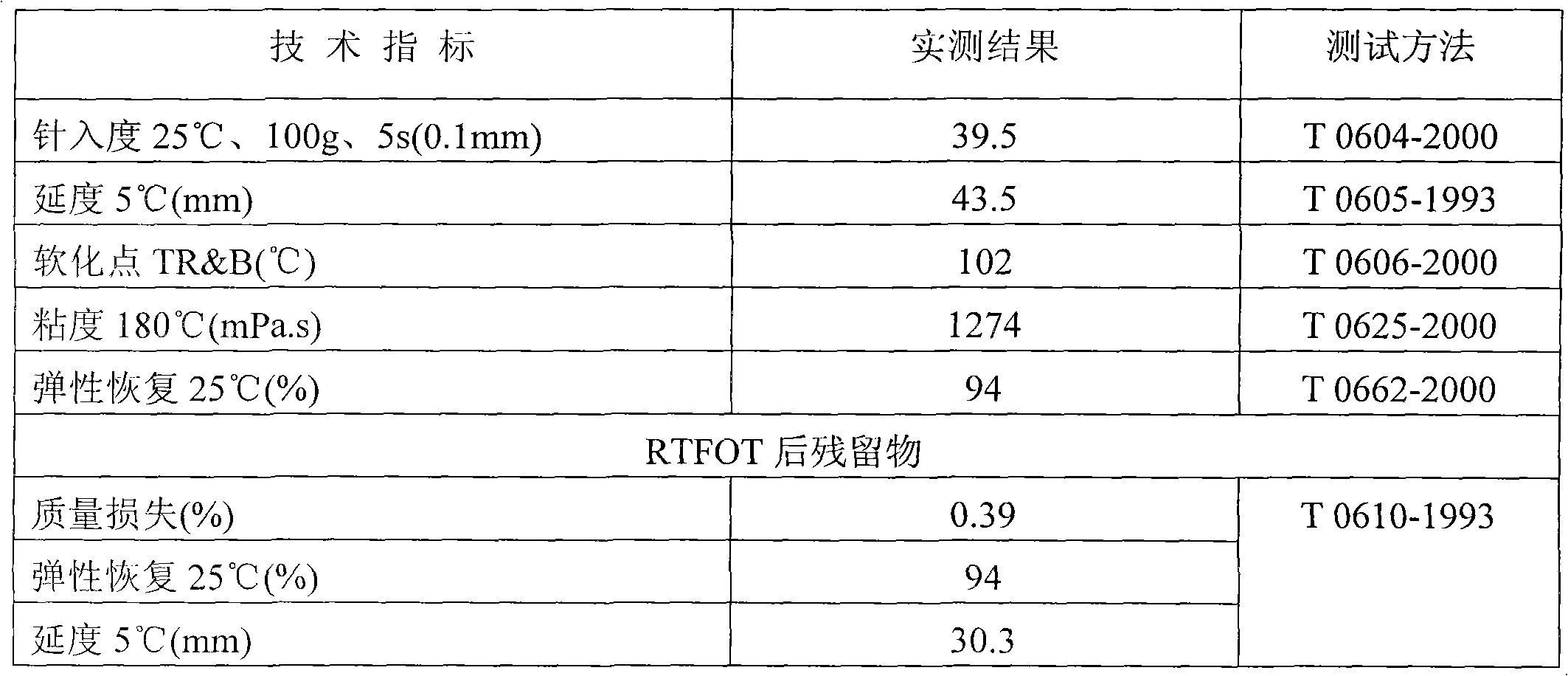

[0036] The performance of the high-strength modified asphalt in Example 1 is shown in Table 1.

[0037] Table 1 Performance of the high-strength modified asphalt in Example 1

[0038]

Embodiment 2

[0040] The group distribution is as follows:

[0041] The distribution ratio of high-strength modified asphalt is as follows:

[0042] The component mass percentage is (%)

[0043] Zhonghai 70# Asphalt 82

[0044] High-strength asphalt modifier for pouring asphalt concrete 18

[0045] The composition ratio of high-strength asphalt modifier for castable asphalt concrete is as follows:

[0046] Component mass parts

[0047] Modifier 45 parts

[0048] Enhancer 8 parts

[0049] Viscosity reducer 47 parts

[0050] According to the above raw material ratio, the following process is installed:

[0051] Step 1: Heat up the Zhonghai 70# bitumen in the bitumen storage tank to 110°C by circulating heating oil and keep it at a constant temperature for 50 minutes for dehydration.

[0052] Step 2: Heat up to 185°C, stir and shear at a speed of 1000r / min, and add high-strength asphalt modifier for pouring asphalt concrete at the same time. After the high-strength asphalt modifier modifier for pouring asphal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com