Production process of inner magnetic rotor of magnetic drive pump

A technology of internal magnetic rotor and production process, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids. It can solve problems such as uneconomical, complicated processes, and difficult welding, and achieve low production costs. The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

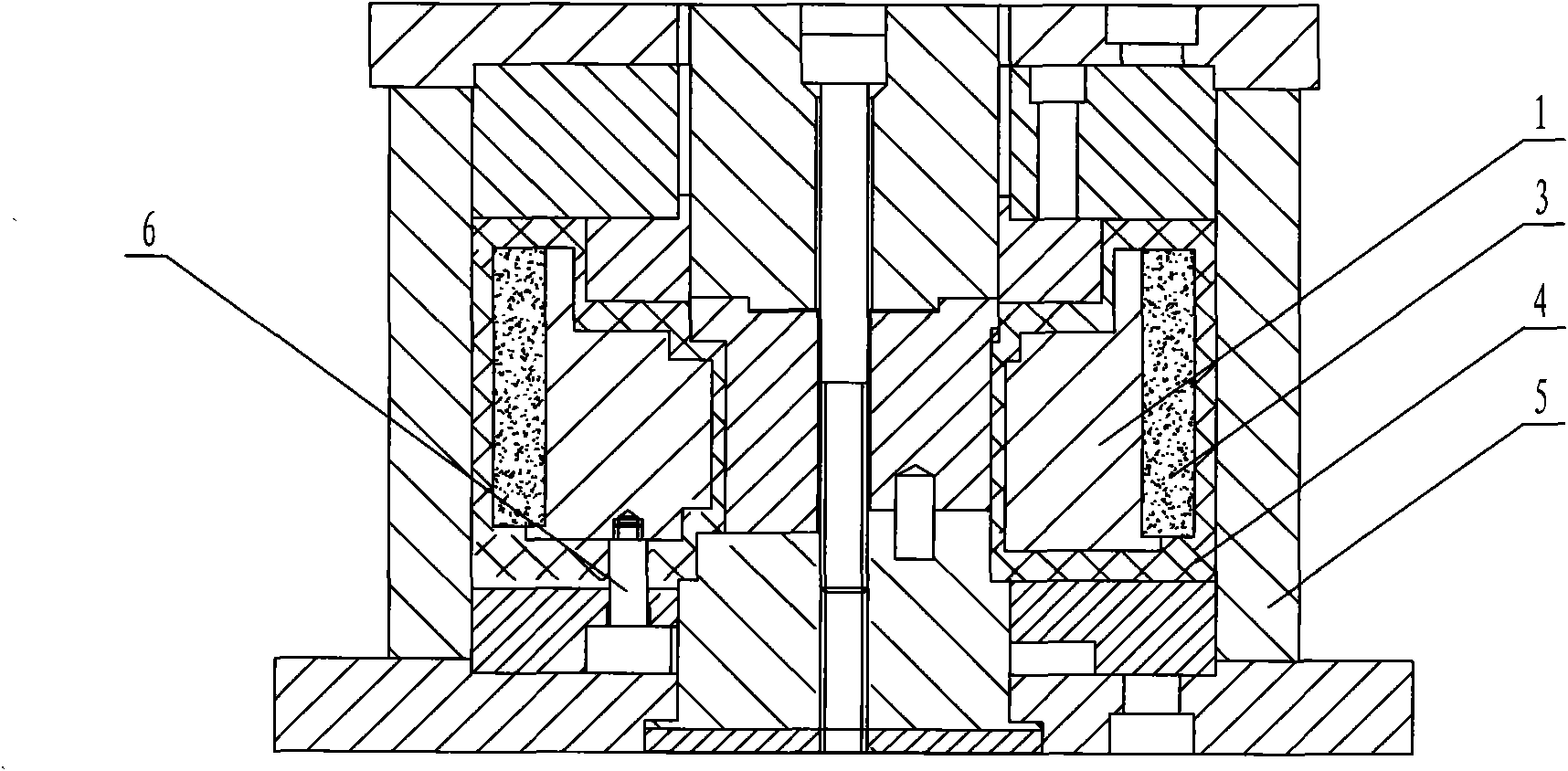

[0021] The production process of the inner magnetic rotor of a magnetic pump is completed by the following production steps:

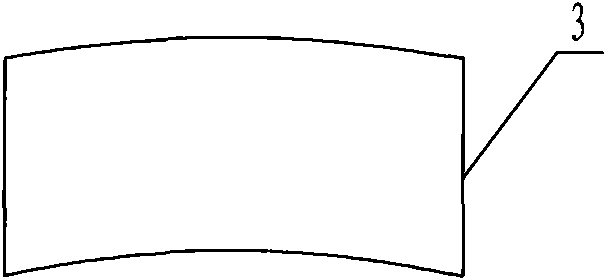

[0022] (a) The inner magnetic rotor base 1 is made of carbon steel, and the phenolic-acetal adhesive is evenly coated on the outer surface of the cleaned inner magnetic rotor base 1 with a thickness of 0.2-0.3 mm. The magnetic material 3 is made of high temperature resistant The magnetic material samarium cobalt (the properties of the magnetic material are shown in the table below), and then the magnetic material 3 is pasted on the inner magnetic rotor base 1, and cured at 180°C for 2 hours;

[0023]

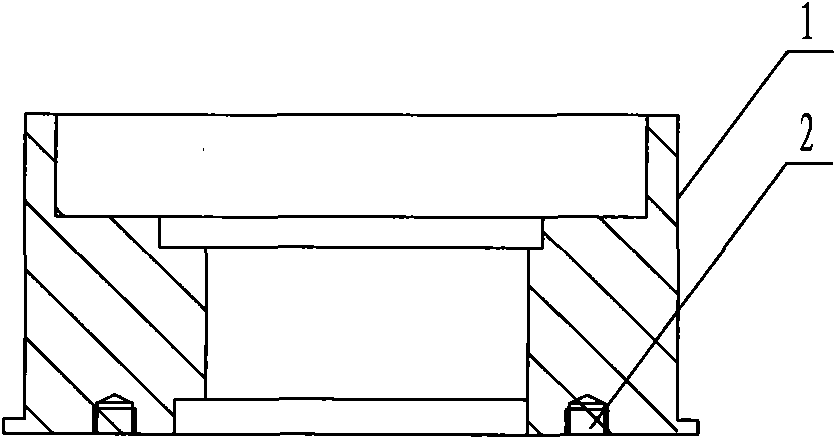

[0024] (b) Suspend the inner rotor base body 1 pasted with the magnetic material through the support column 6 provided at the bottom thereof, and put it into the mold 5;

[0025] (c) Add 920 grams of polyperfluoroethylene propylene (4) into the mold, put it into a heating furnace, heat it to 310°C ± 5°C, and keep it warm for 2 hours;

[0026] (d) Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com