3D heat radiating module type high-power LED illuminating device

A technology of LED lighting and heat dissipation module, which is applied to lighting devices, lighting device parts, lighting device cooling/heating devices, etc., can solve the problems of easily polluted total reflection surface, poor heat dissipation effect, and reduced reflection efficiency, etc. , to achieve the effect of good heat dissipation, flexible design and high light utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

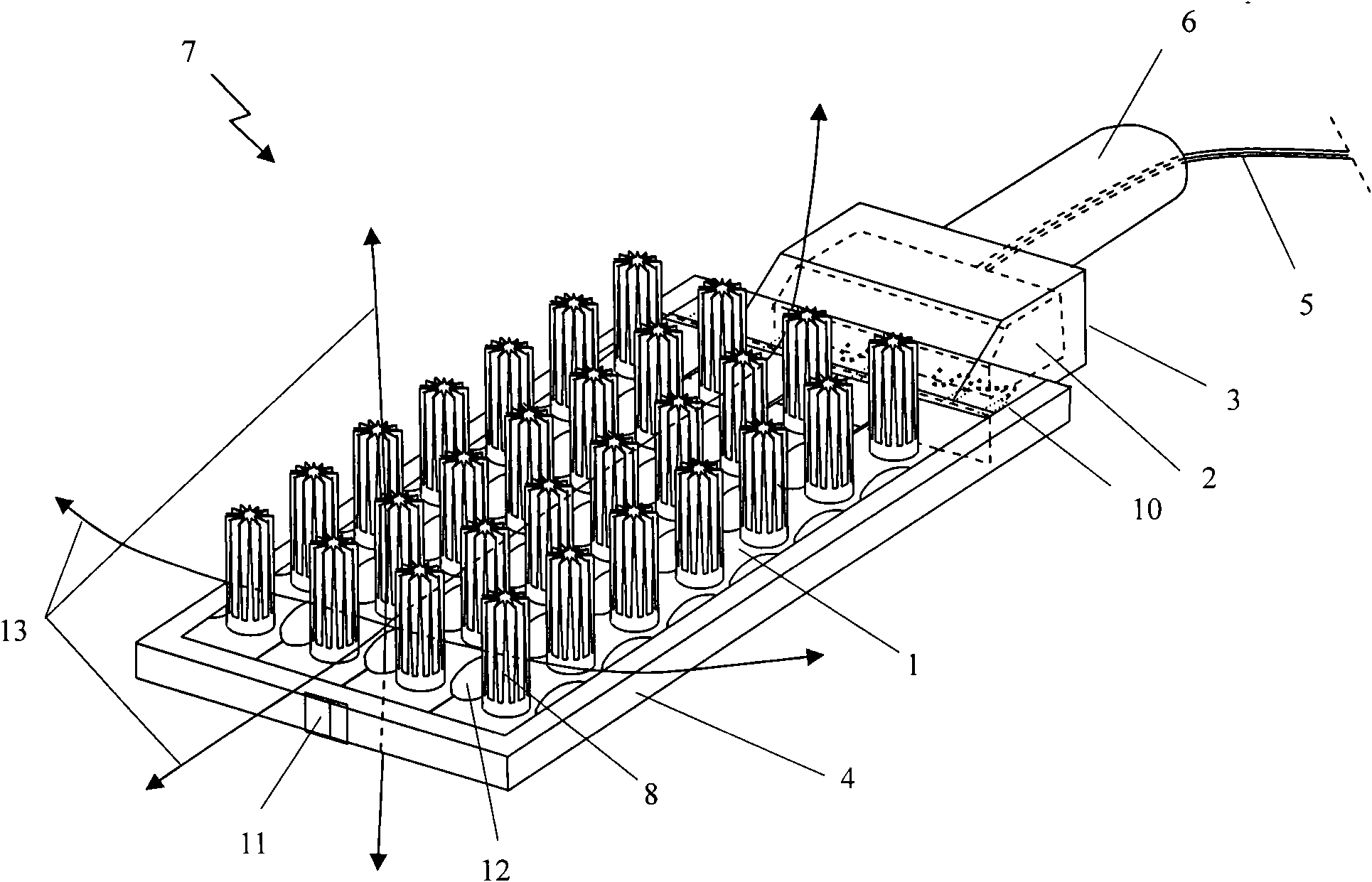

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of an embodiment of the 3D heat dissipation modular high-power LED lighting device of the present invention. It includes: at least one detachable high-power LED module 1, at least one LED driver 2 and driver housing 3, a module fixing device 4, an electrical connection device 5 and a mechanical fixing device 6, which are connected to each other to form a lighting device 7 , figure 1 An example of a road light is shown.

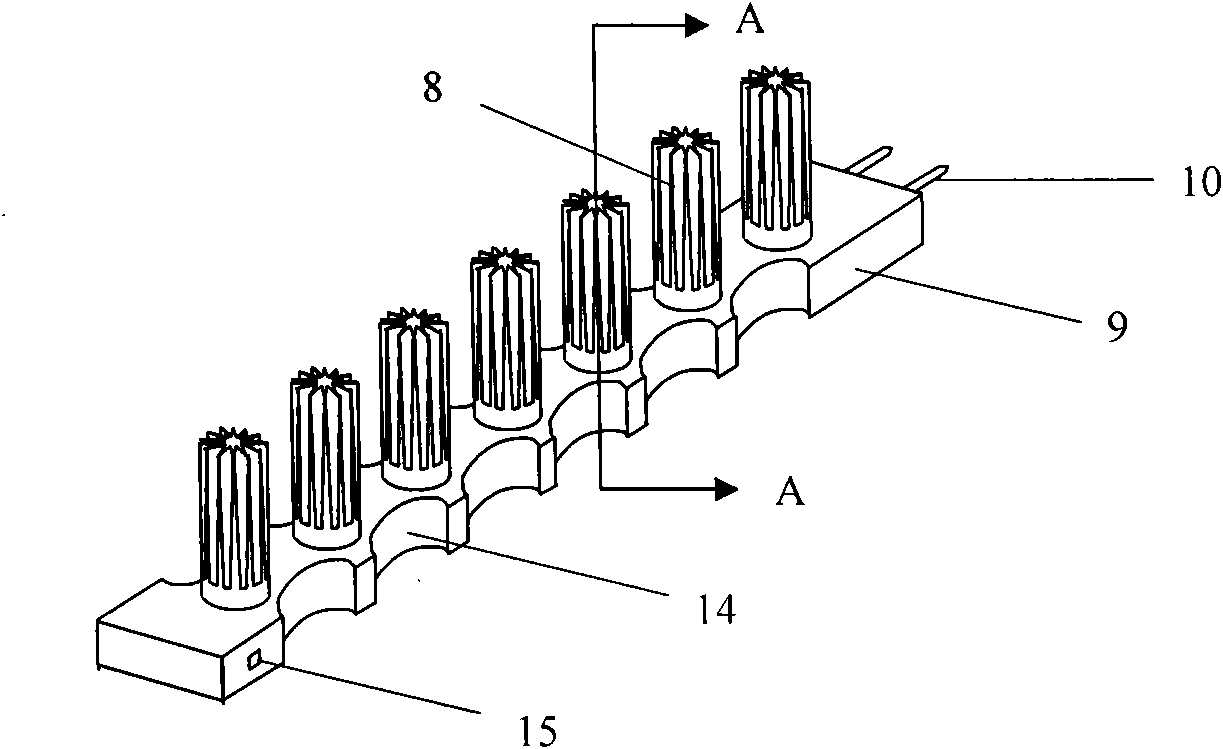

[0026] The LED module 1 such as figure 2 As shown, it includes at least one heat sink 8, a lamp body substrate 9, and an electrical connector 10. For the specific structure of the LED module, see image 3 and 4 shown.

[0027] Several LED modules 1 are spliced together to form a lighting device, figure 1 Shown is an example composed of four modules 1; each module is fixed to each other by a module ...

Embodiment 2

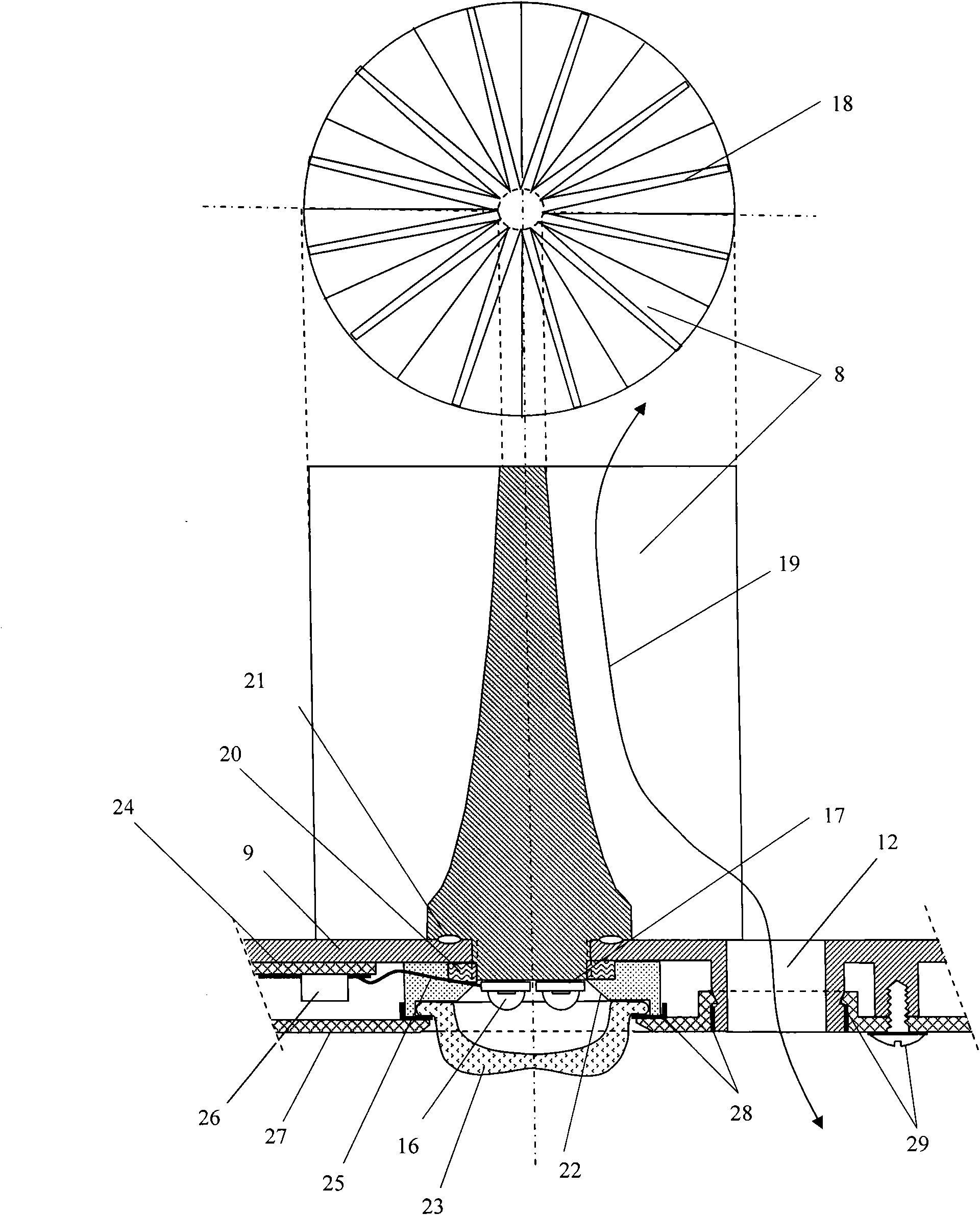

[0034] image 3 It is a partial section of an embodiment of the LED module of the present invention ( figure 2 A-A) Schematic diagram of the structure. In the figure, 16 is at least one high-power LED single tube, 8 is a radiator, and the heat sink of the LED is directly fixed on the radiator through a heat-conducting material 17; the radiator 8 has a series of cooling fins 18 parallel to the radiator axis; 9 Be lamp body substrate, 12 is the vent hole of lamp body substrate 9 sides, and 19 represents the air flow that circulates from vent hole; The fixing device 20 that radiator is used is fixed on lamp body substrate 9, and 21 is sealing rubber ring; LED 16 around There is a light reflector 22 for reflecting the light emitted by the LED to the side to the front; the front of the LED has a light distribution lens 23 .

[0035] Part of the loose blades 18 of the heat sink may be located above the air holes 12, so that the heat sink can dissipate heat better.

[0036] The h...

Embodiment 3

[0041] Figure 4 It is a partial section of another embodiment of the LED module of the present invention ( figure 2 A-A) Schematic diagram of the structure. It is characterized in that the radiator 8 and the lamp body substrate 9 are integrated; the LED is installed on the metal-based circuit board 30, and the metal-based circuit board 30 is connected to the radiator 8 through a heat-conducting material; lens.

[0042] For lamps that do not need to gather light, the light distribution lens 23 and the light reflection ring 22 may not be used; the light exit surface of the module 1 may have a light-transmitting plate or a curved light-transmitting cover to replace the sealing plate 27 . Figure 4 The meanings represented by other numbers in image 3 in the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com