High temperature flame divider and fuel and gas heater

A gas heater and flame technology, which is applied in the fields of high temperature flame splitters, fuel oil and gas heaters, can solve the problems of heat exchange device ablation, large thermal energy loss, and high outlet flame temperature, and achieve thermal energy loss and exhaust pollution. The effect of low, increased area, and improved heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

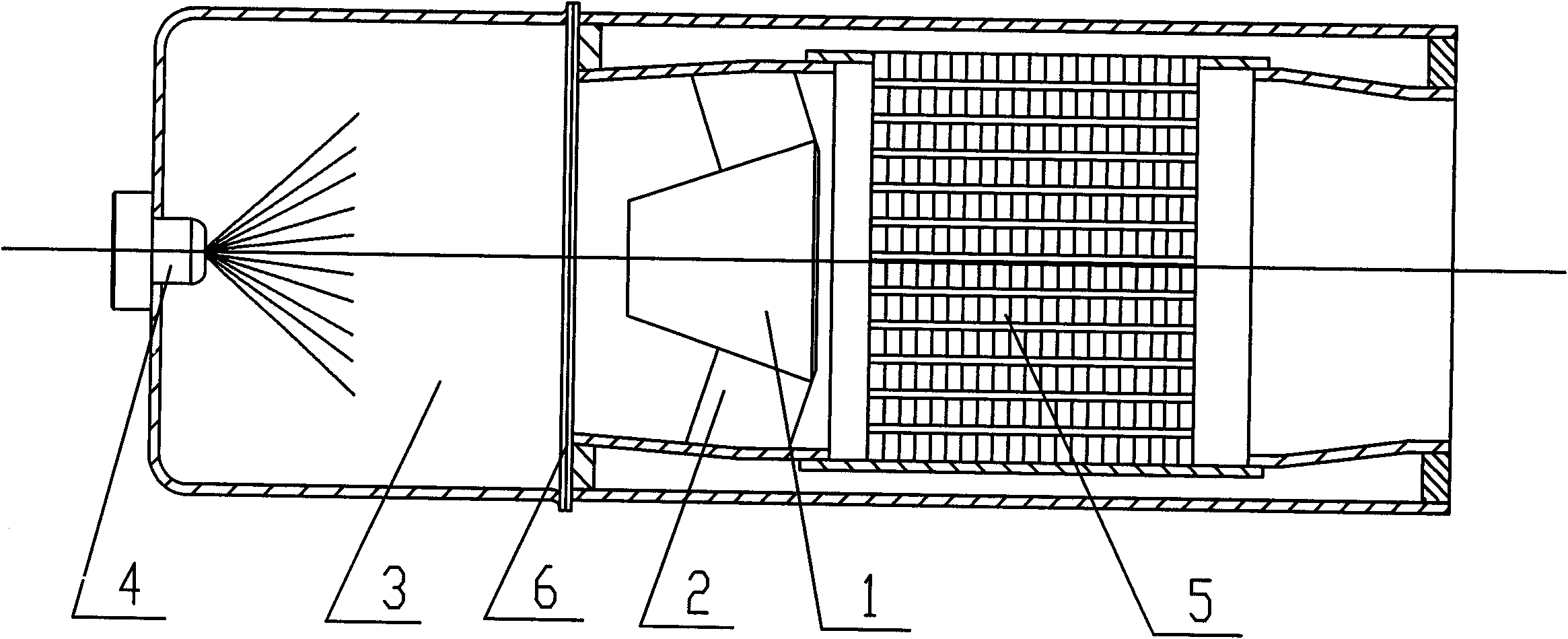

[0021] The present invention will be described below in conjunction with the accompanying drawings.

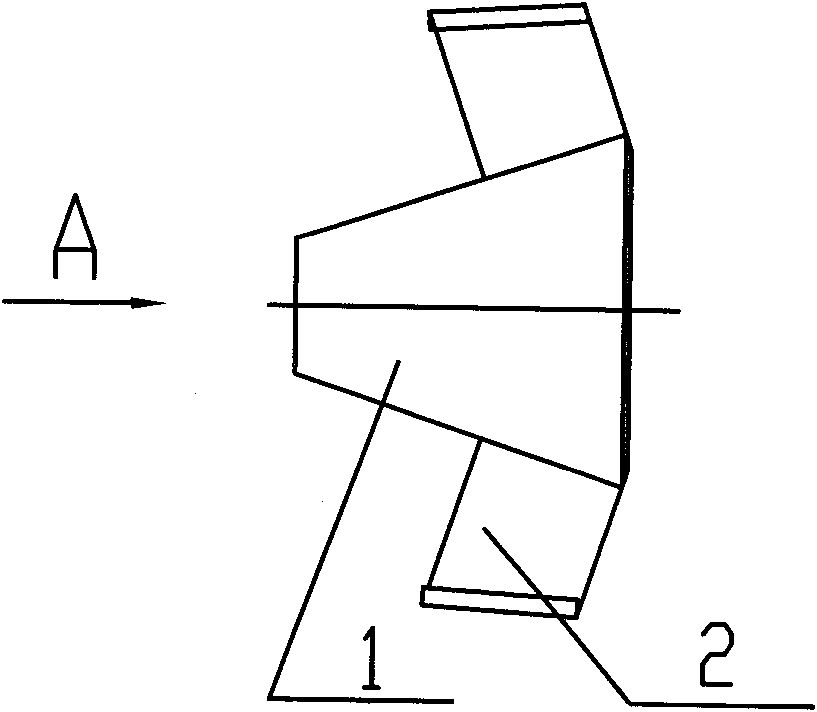

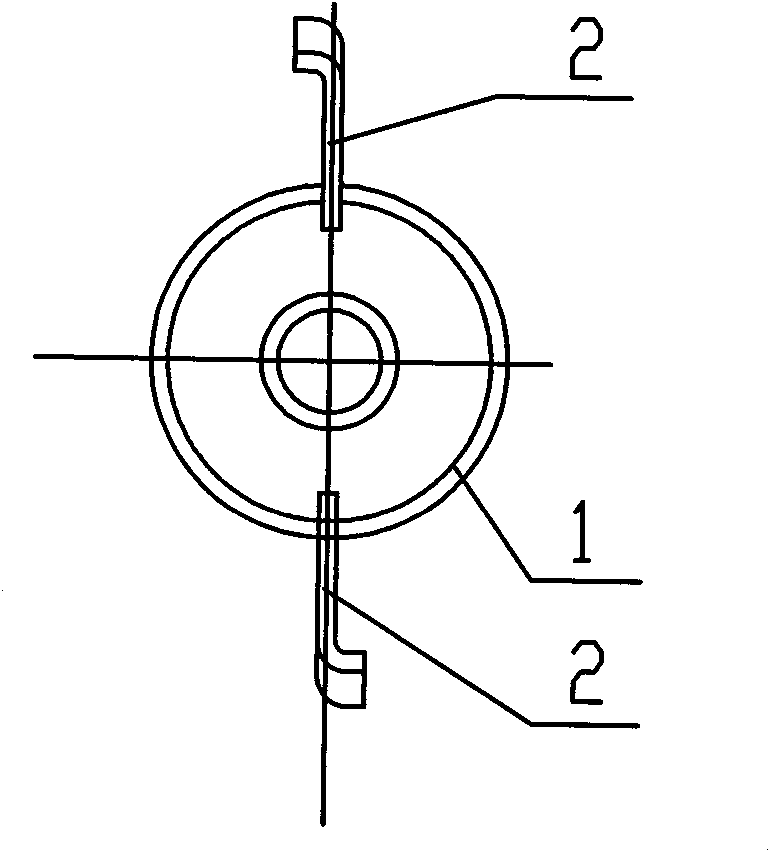

[0022] figure 1 It is the structural representation of the high-temperature flame flame distributor of the present invention, figure 2 for figure 1 A view from direction A. The high-temperature flame distributor includes a guide body 1 and two support plates 2 welded together with the guide body 1 for fixed support. The support plates 2 are symmetrically arranged on both sides of the guide body 1 and along the direction of the central axis of the guide body 1. It is provided that the guide body 1 is a through hollow frustum with a certain taper made of heat-resistant steel plate 1Cr25Ni20Si2 with a thickness of 3 mm to 5 mm or other heat-resistant metals. A special high-temperature heat-resistant ceramic coating can be evenly sprayed on the surface of the diversion body 1. The high-temperature heat-resistant ceramic coating is a ceramic sprayed by flame nozzles of aerospac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com