Method for measuring material glass transition based on optical change

A glass transition and optical technology, applied in chemical instruments and methods, polycrystalline material growth, color/spectral characteristic measurement, etc., can solve the problems of unintuitive phenomena, complicated operation, and low accuracy of measurement results, and achieve intuitive phenomena , simple operation, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

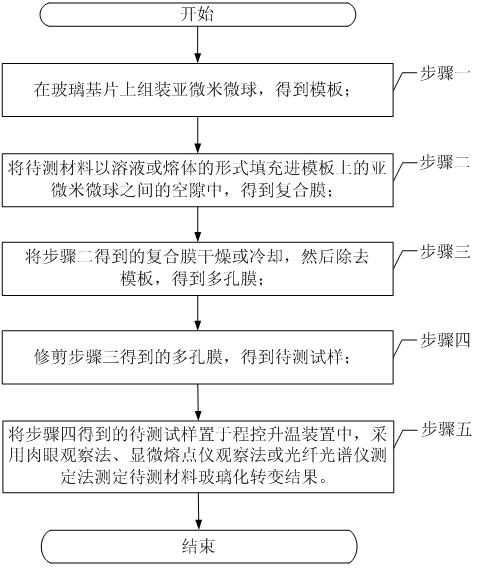

[0021] Specific implementation mode 1. Combination figure 1 Illustrate this specific embodiment, the method for measuring material glass transition based on optical change, it is realized by the following steps:

[0022] Step 1, assembling submicron microspheres on a glass substrate to obtain a template;

[0023] Step 2, filling the material to be tested into the gap between the submicron microspheres on the template in the form of solution or melt to obtain a composite film;

[0024] Step 3, drying or cooling the composite membrane obtained in step 2, and then removing the template to obtain a porous membrane;

[0025] Step 4, trimming the porous membrane obtained in step 3 to obtain the sample to be tested;

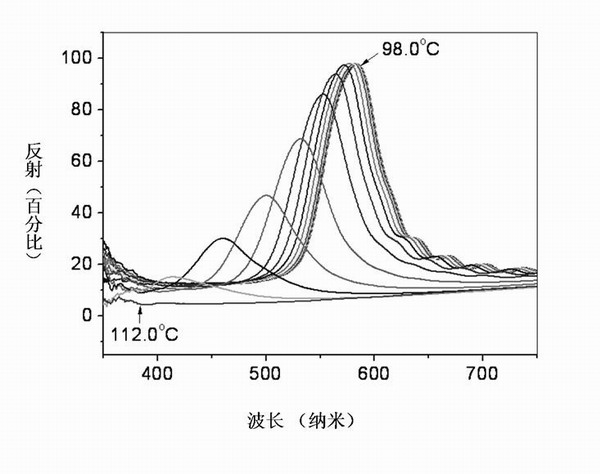

[0026] Step 5. Place the sample to be tested obtained in Step 4 in a program-controlled heating device, and measure the glass transition result of the material to be tested by visual observation, micro melting point instrument observation or optical fiber spectrometer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com