Forming device and preparation method for plastic foam product

A technology of plastic foam and molding device, which is applied to the field of molding device and preparation of plastic foam products, can solve the problems of limited application range, long production cycle, complicated process, etc., and achieves simple process flow, no waste of raw materials, fusion bonding solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

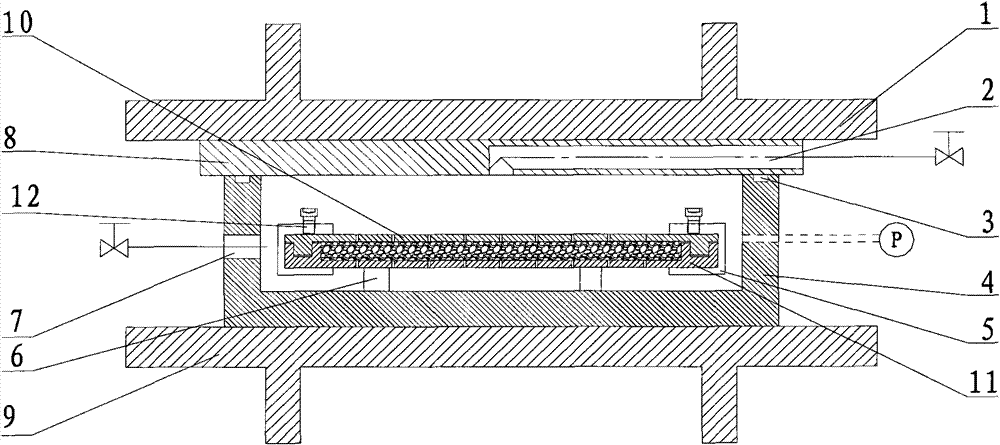

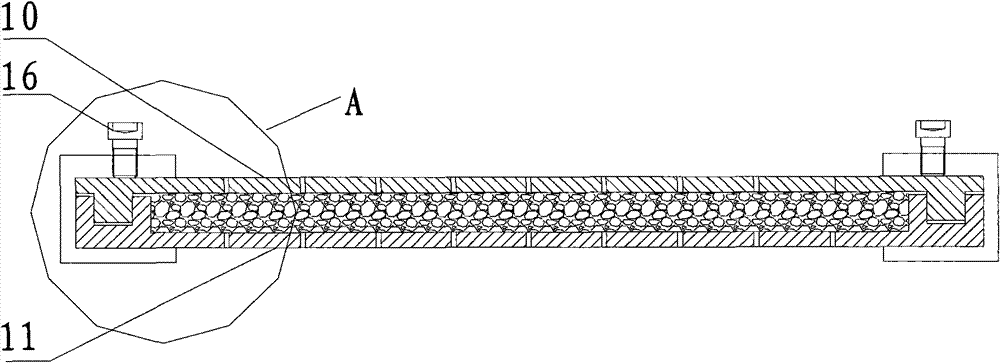

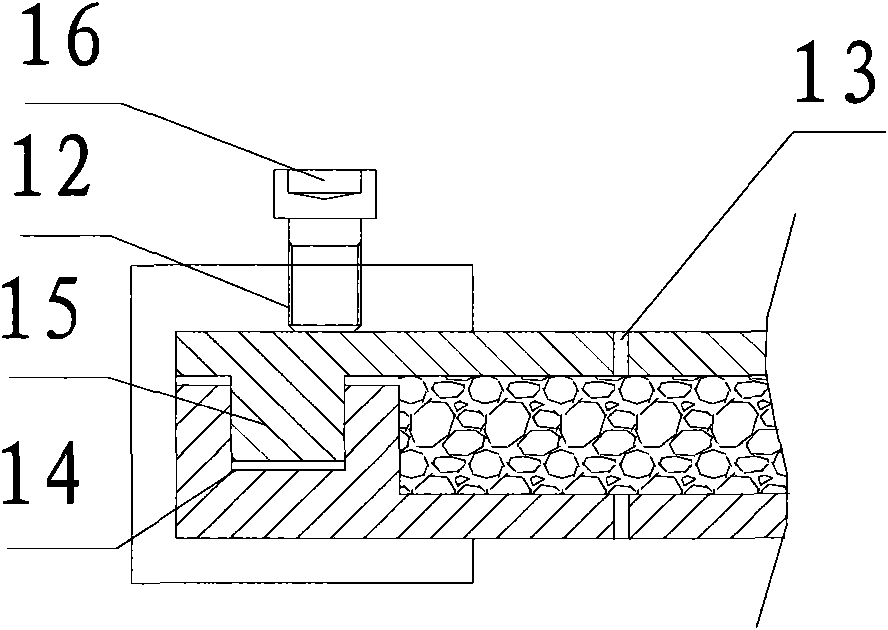

[0049] Polystyrene foam beads (density 30Kg / m 3 , Wuxi Xingda) to fill the mold cavity of the above-mentioned molding device, put the mold into the steam generator, add 150ml of water to the water tank 4 of the steam generator, cover the cover plate 8, and place the molding mechanism on Between the upper hot pressing plate 1 and the lower hot pressing plate 9 of the hot press, the upper hot pressing plate 1 and the lower hot pressing plate 9 are heated and pressurized, so that the internal pressure of the steam generator reaches 0.15-0.2 MPa, and the pressure is released after 4 minutes of molding. Press, take out the mold, cool naturally to normal temperature, remove the mold, and obtain a polystyrene foam board.

[0050] The melt-bonded polystyrene foam beads in the polystyrene plastic foam board are not easy to scatter.

Embodiment 2

[0052] Polypropylene foam beads (density 30Kg / m 3 , Juner New Material Co., Ltd.) to fill the mold cavity of the above-mentioned molding device, put the mold into the steam generator, add 200ml of water to the water tank 4 of the steam generator, cover the cover plate 8, and mold The mechanism is placed between the upper hot pressing plate 1 and the lower hot pressing plate 9 of the hot pressing machine, and the upper hot pressing plate 1 and the lower hot pressing plate 9 are heated and pressurized to make the internal pressure of the steam generator reach 0.6-0.7MPa and form After 2 minutes, the pressure was released, the mold was taken out, cooled naturally to room temperature, and the mold was removed to obtain a polypropylene plastic foam board.

[0053] The melt-bonded polypropylene foam beads in the above-mentioned polypropylene plastic foam board are not easy to scatter.

Embodiment 3

[0055] Polylactic acid foam beads (density 120Kg / m 3 , Juner New Material Co., Ltd.) to fill the mold cavity of the above-mentioned molding device, put the mold into the steam generator, add 200ml of water to the water tank 4 of the steam generator, cover the cover plate 8, and mold The mechanism is placed between the upper hot pressing plate 1 and the lower hot pressing plate 9 of the hot pressing machine, and the upper hot pressing plate 1 and the lower hot pressing plate 9 are heated and pressurized to make the internal pressure of the steam generator reach 0.15-0.2 MPa, and the molding After 3 minutes to 4 minutes, release the pressure, take out the mold, cool naturally to room temperature, remove the mold, and obtain a polylactic acid plastic foam board.

[0056] The melt-bonded polylactic acid foam beads in the polylactic acid plastic foam board are not easy to scatter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com