Equal-pressure virtual isolation check valve sealing test method and equipment

A test method and technology of test equipment, applied in the field of detection, can solve the problems of difficult isolation, small space, and inability to quantify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

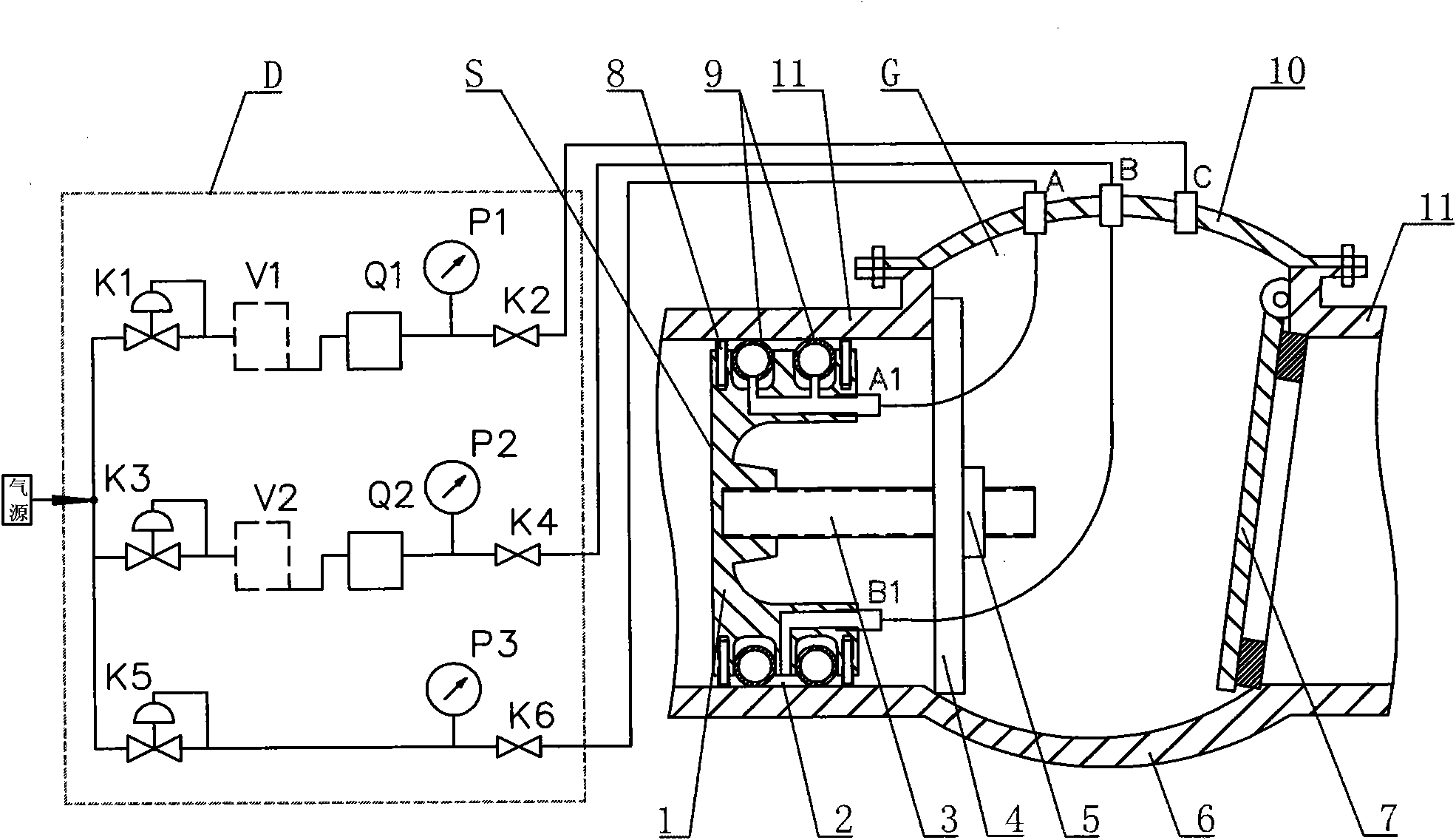

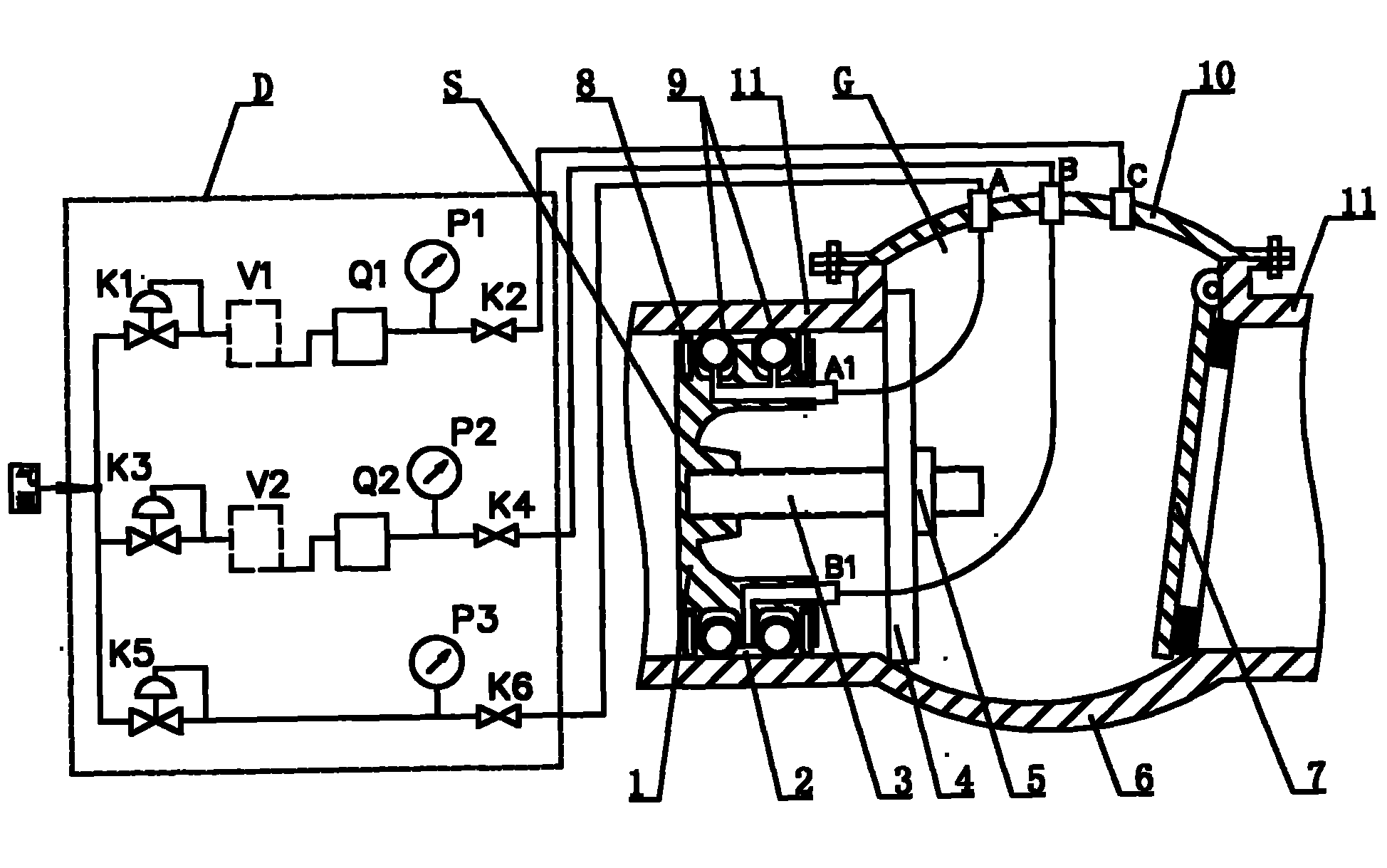

[0021] figure 1 In the figure, the left half is the leak detector D, and the right half is the isobaric isolation component S that realizes isobaric virtual isolation.

[0022] Leak detector D shares the same air source and has three inputs:

[0023] The first route consists of regulating valve K1, container V1, multi-range flowmeter Q1, pressure gauge P1 and shut-off valve K2. It is used for filling the valve cavity and measuring the leakage rate;

[0024] The second route consists of regulating valve K3, container V2, flow meter Q2, pressure gauge P2 and shut-off valve K4. It is used for pressurizing the space 2 between the double sealing rings 9 and measuring the leakage rate;

[0025] The third route consists of regulating valve K5, pressure gauge P3 and cut-off valve K6. Used to pressurize the seal ring.

[0026] The check valve G to be tested consists of a valve body 6, a valve plate 7, a valve cover 10, a valve inlet and outlet pipe 11, and three test joints A (sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com