Boiler combustion rate self-optimizing method based on PID control policy

A boiler combustion and control strategy technology, applied in the direction of electric controllers, controllers with specific characteristics, etc., can solve problems affecting the realizability, ease of use and portability of algorithms, unfavorable real-time control, and easy oscillations, etc. , to achieve optimized real-time control, fast calculation speed and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

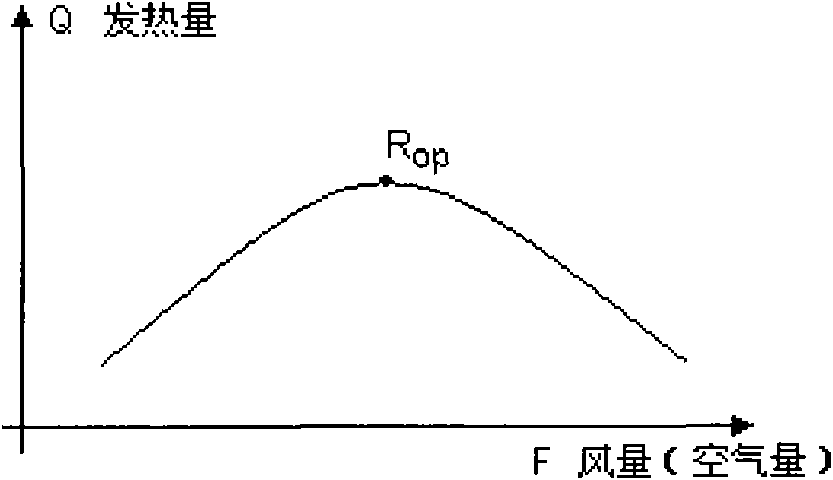

[0041] In the boiler system, when the unit fuel volume is mixed with the air volume (air volume) proportioned according to the ratio R, if the calorific value is the maximum value, then the boiler combustion rate is the optimal value at this time, and the "fuel-air volume" at this time "The ratio R is the optimal value R op . This relationship can be described by the F-Q curve (air volume-heat curve), which expresses the relationship between air volume and calorific value when the amount of fuel remains constant, such as figure 1 shown.

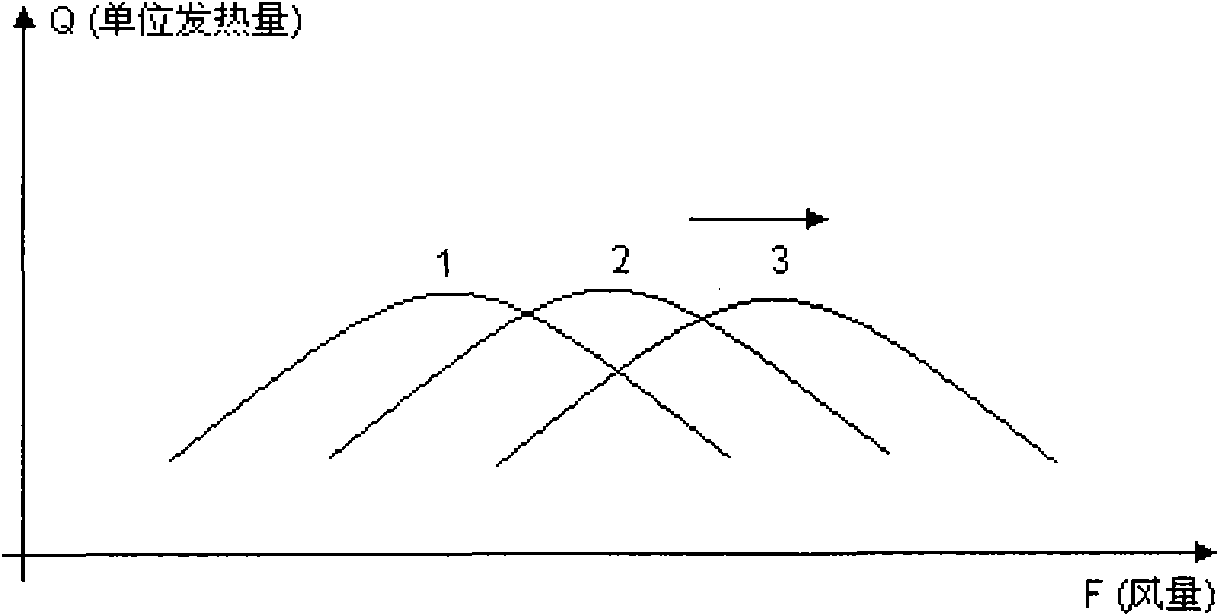

[0042] When the amount of fuel changes, the figure 1 Based on this, a family of curves can be formed, such as figure 2 shown. Each curve in the figure can express the relationship between the air volume and the calorific value when the fuel volume is a certain value. In the curve family, the further to the right the curve represents the more fuel, that is, the fuel amount of curve 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com