Process of 0.5mum vertical JFET (Junction Field-effect Transistor)

A process and epitaxial layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low chip integration, large device size, poor device performance, etc., to improve integration and reduce device size. , to ensure the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

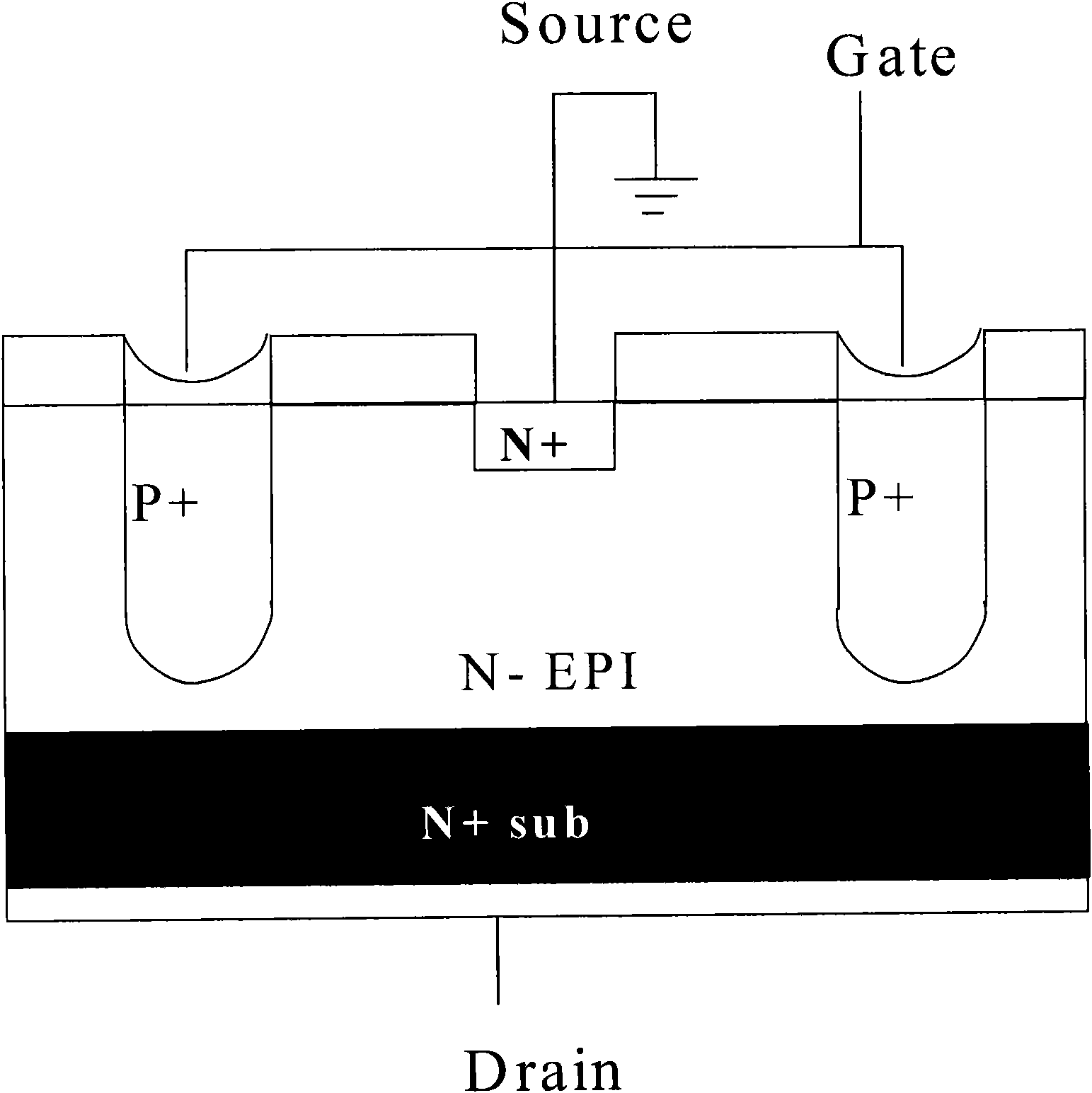

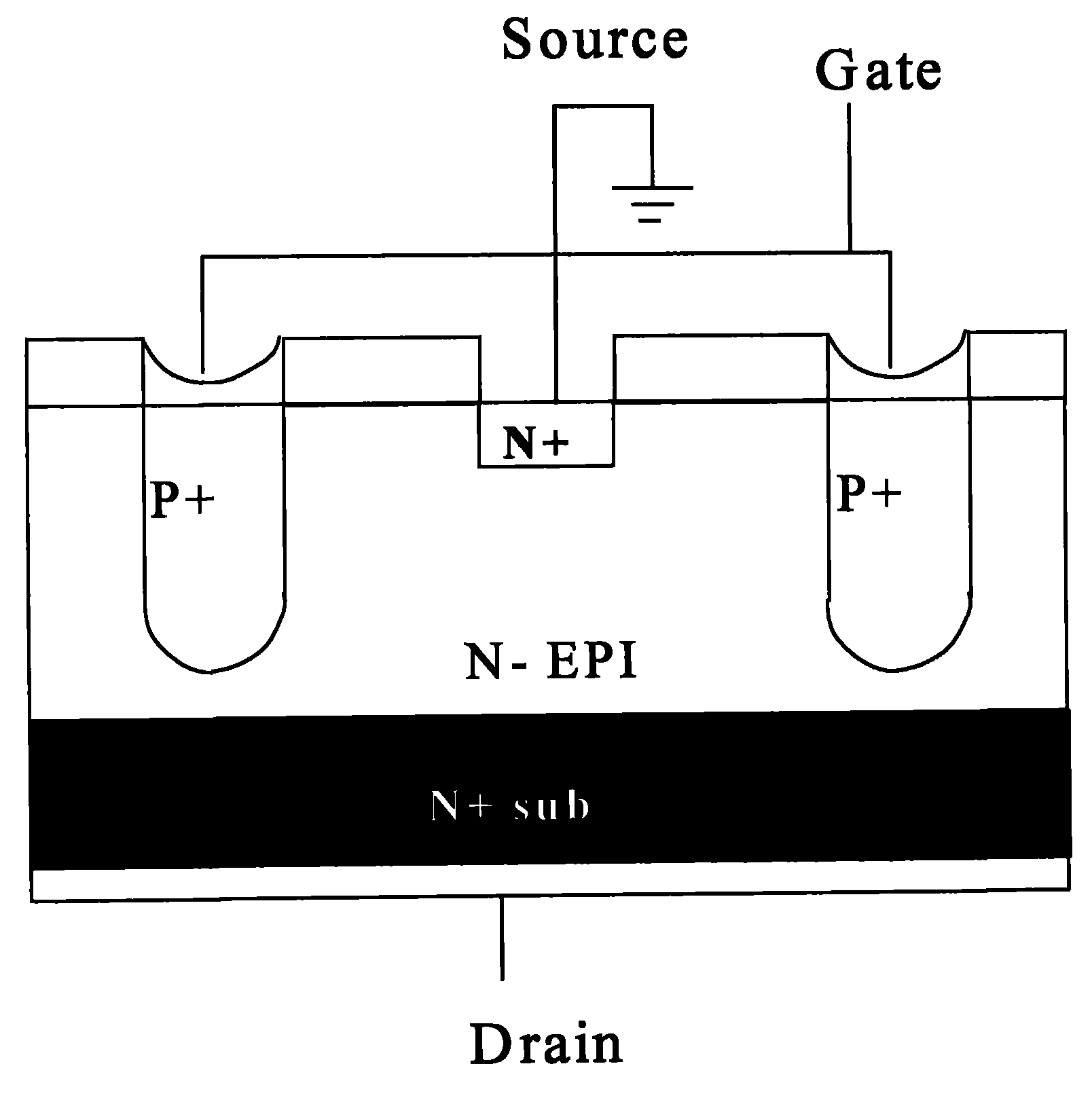

[0035] The invention discloses a 0.5-micron vertical JFET process. After growing an epitaxial layer on a substrate, grooves are opened in the region where doping is required, and doping implantation is performed in the grooves. The doping implantation is of the opposite type to that of sinking the bottom and the epitaxial layer. s material.

[0036] In one embodiment, the groove is realized by photolithography process, and further includes smoothing the sidewall of the groove.

[0037] In one embodiment, the substrate is an N-type heavily doped substrate, and the epitaxial layer is an N-type lightly doped epitaxial layer. Doping implantation is to implant P-type polysilicon or epitaxial layer.

[0038] In one embodiment, the 0.5 micron vertical JFET process further includes forming the source by photolithography.

[0039] refer to figure 1 as shown, figure 1 A structural diagram of a JFET device fabricated according to the 0.5 micron vertical JFET process of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com