Method for manufacturing nano-wire piezoelectric device

A piezoelectric device and manufacturing method technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of low output power, nanogenerator wear, nanowire and Electrode wear and other problems, to achieve the effect of improving stability and output power, wide application range and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

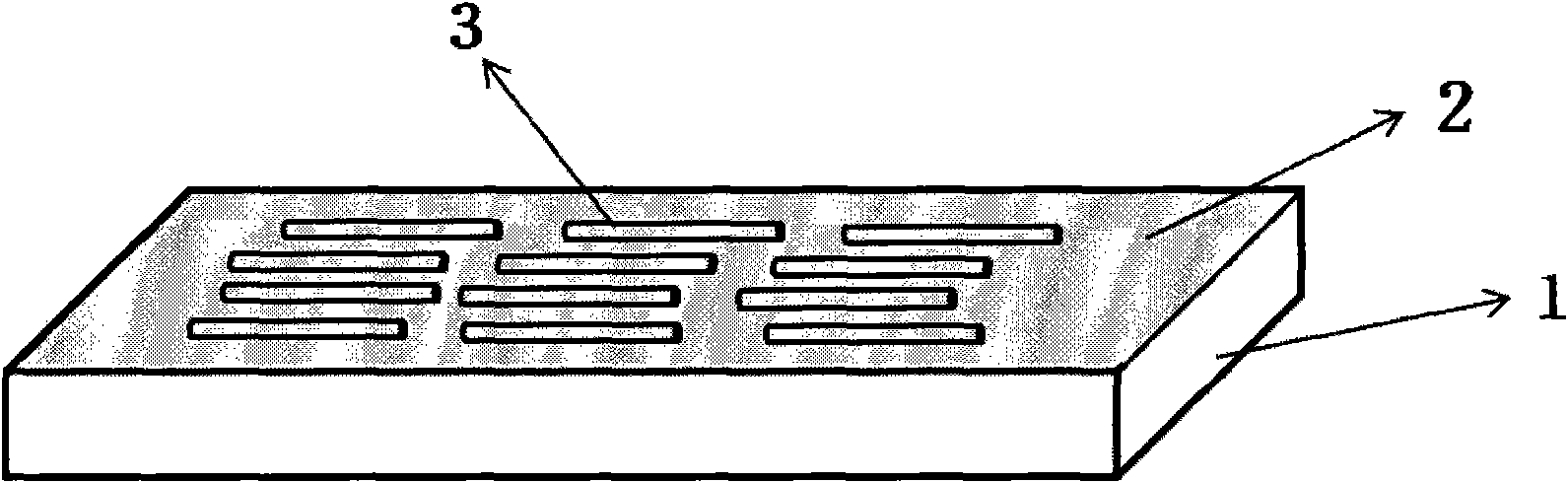

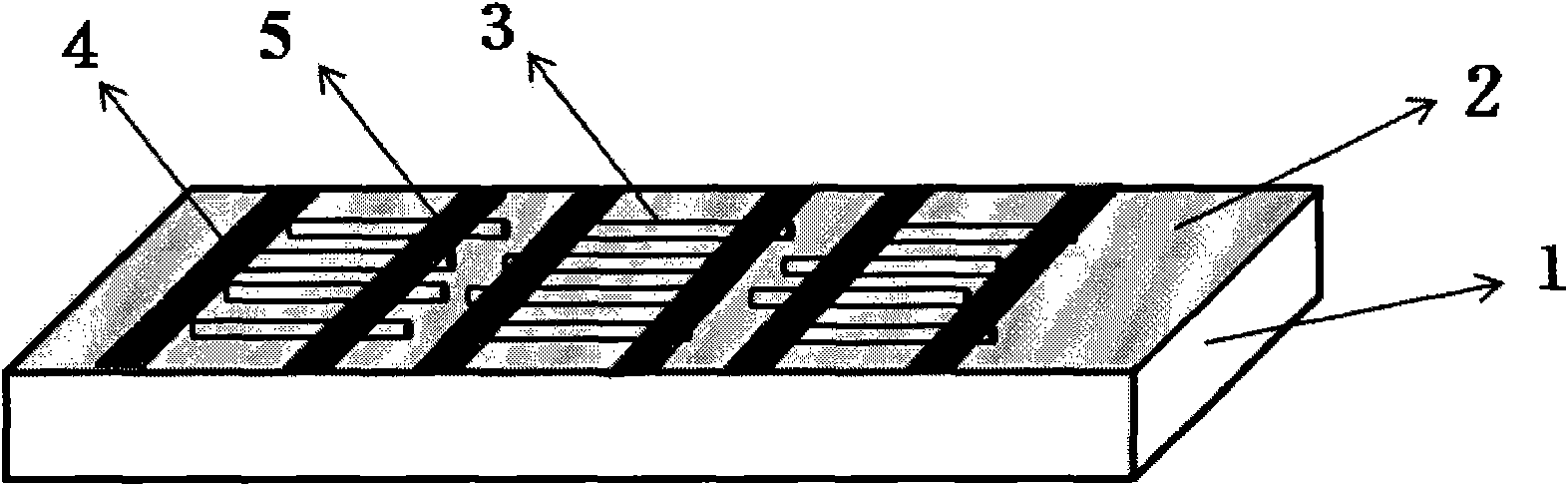

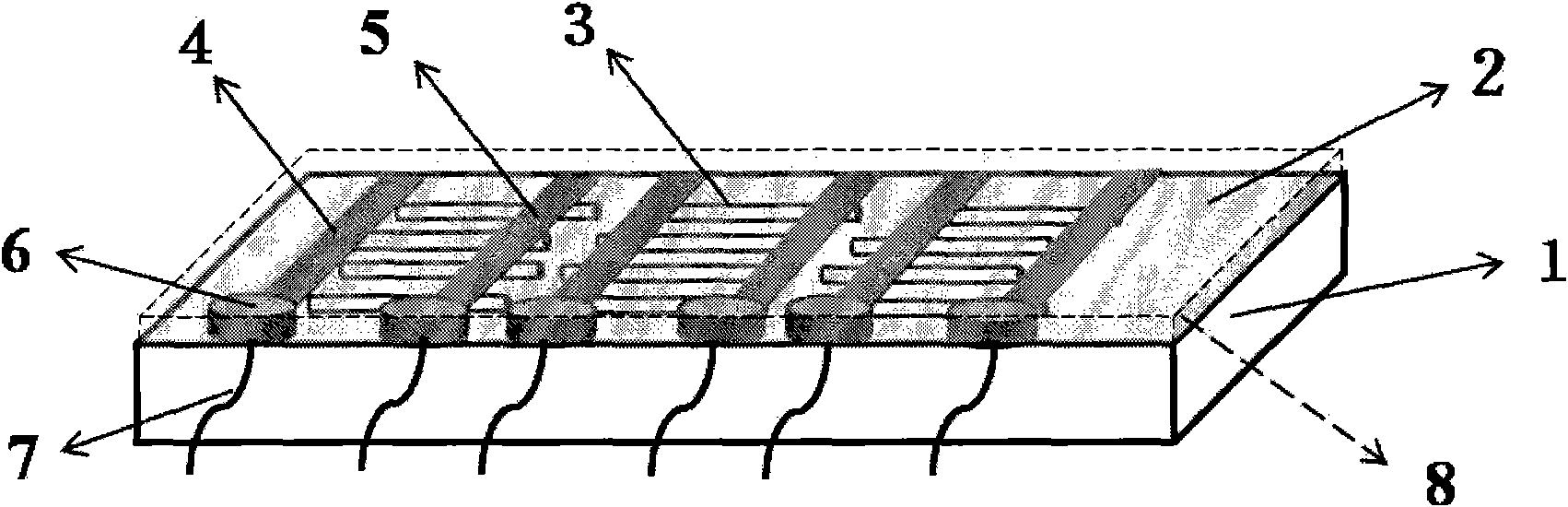

[0026] The invention provides a fabrication and integration method of a large-area parallel arrangement nanowire piezoelectric device. First, a large-area parallel array of nanowires was prepared on the surface of the polyimide film by direct dry transfer method; then, metal source-drain electrodes were prepared on the surface of the above-mentioned nanowire array by using the standard micro-nano lithography process. Next, the metal contacts of the source and drain electrodes are grouted, and the surface of the piezoelectric device is encapsulated with polydimethylsiloxane (PDMS) after the leads are drawn from the contacts, so as to be connected and tested with the outside. Since a large number of nanowires can work simultaneously to convert mechanical energy into electrical energy; therefore, the present invention has better stability and higher output power than a single nanowire piezoelectric device. At the same time, this method is compatible with the traditional semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com