Direct-current booster circuit suitable for micro power inversion

A DC boost circuit and micro power technology, applied in the direction of converting DC power input to DC power output, output power conversion devices, electrical components, etc., can solve the problems of poor waveform quality, difficult debugging, complicated circuits, etc. Achieve the effect of low production cost, high conversion efficiency and simple circuit structure

Inactive Publication Date: 2010-10-13

BEIJING JIAOTONG UNIV

View PDF2 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Traditional inverter devices generally adopt the method of inverting first and then boosting voltage, which has high cost, complex circuit, difficult debugging and poor waveform quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

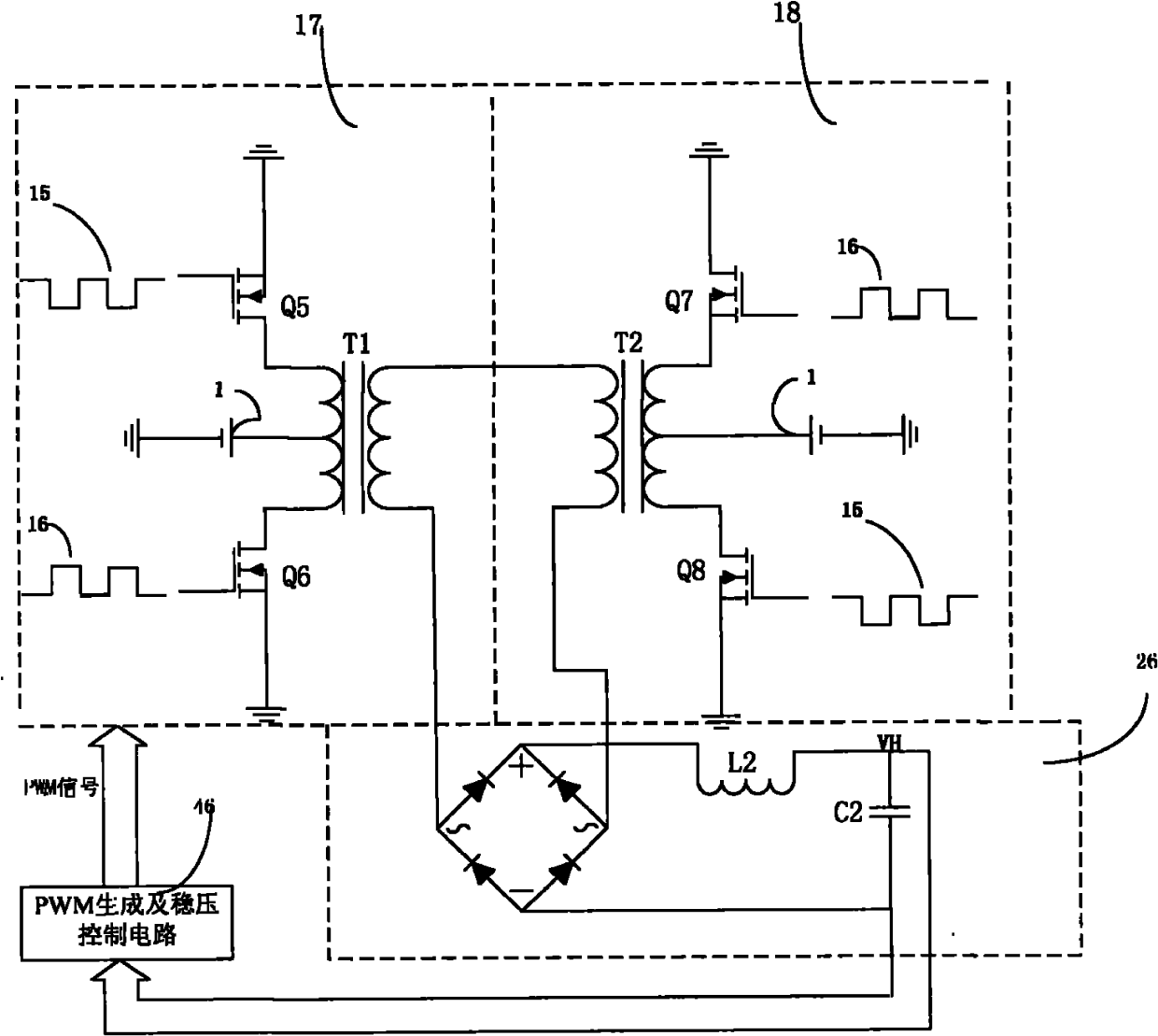

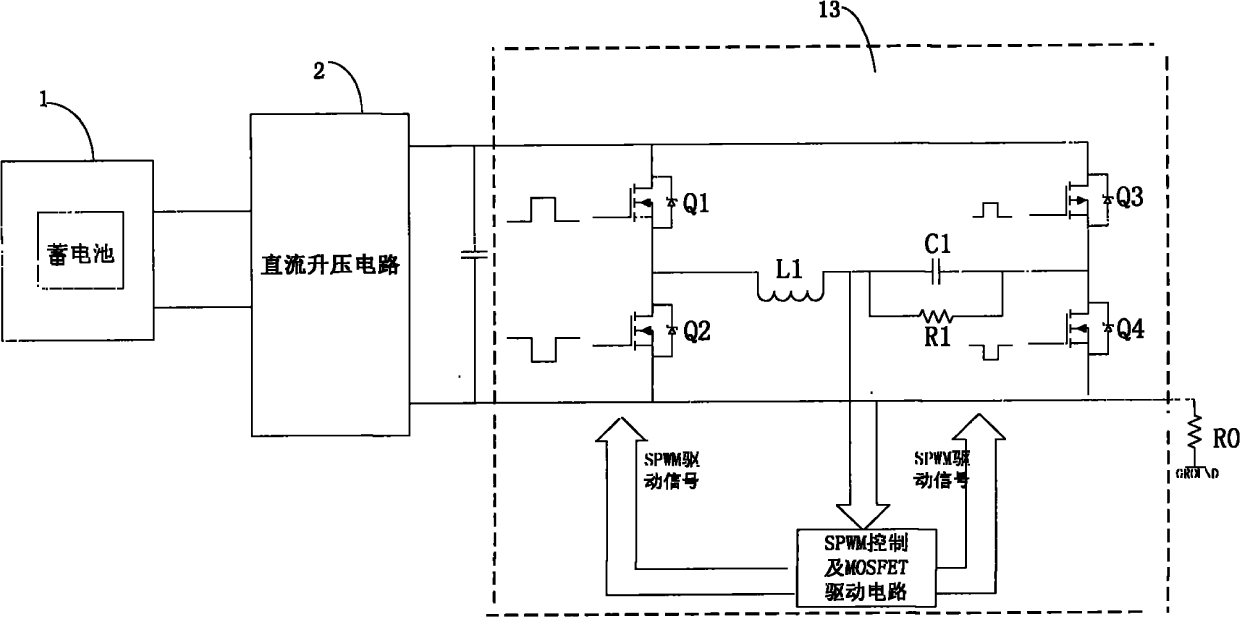

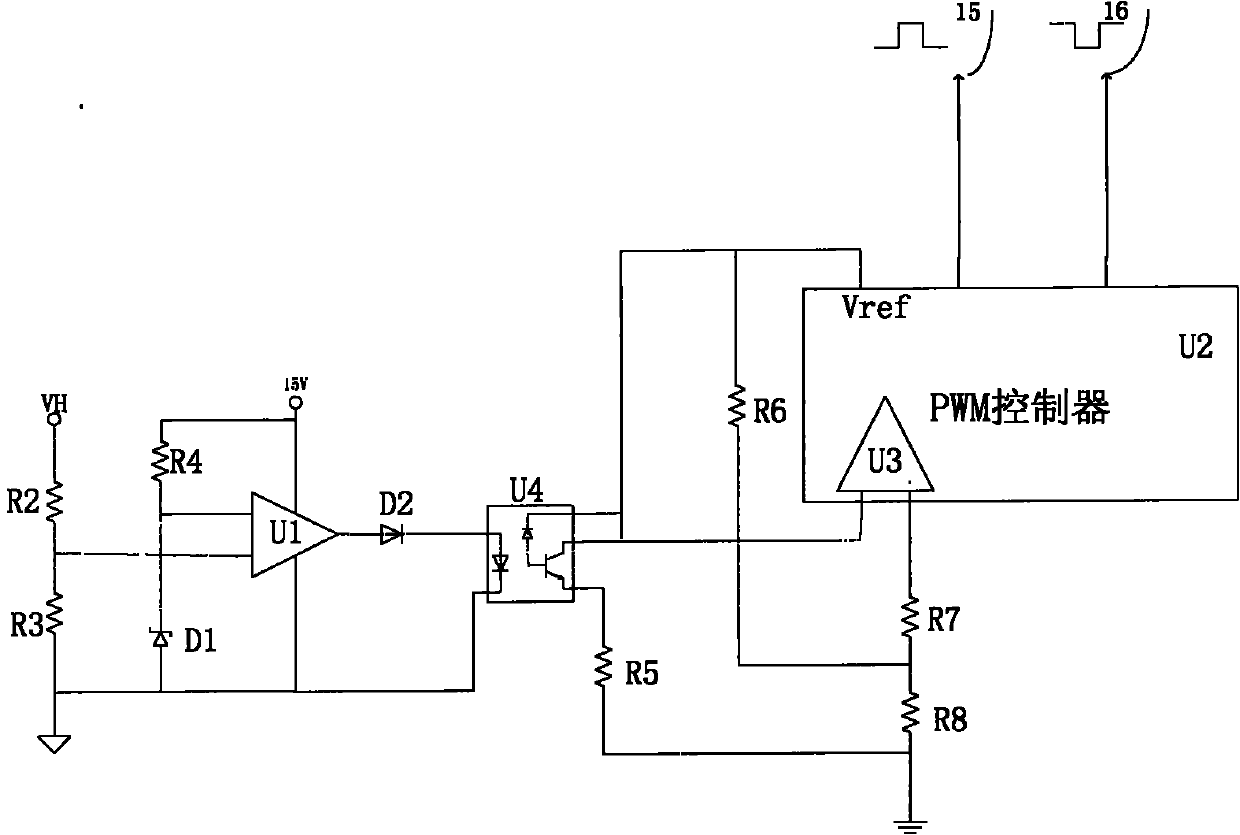

The invention relates to a direct-current booster circuit suitable for micro power inversion, which comprises two symmetrical push-pull circuits, a rectifier and filter circuit and a PWM generating and voltage stabilizing control circuit. Output results of the two symmetrical push-pull circuits are superposed to generate 380V alternating current; the rectifier and filter circuit rectifies and filters the 380V alternating current to generate 330V direct current; and a second resistor (R2) and a third resistor (R3) in the PWM generating and voltage stabilizing control circuit perform voltage partition on the 330V direct current generated by the rectifier and filter circuit, the partial voltage is compared with a reference voltage stabilized by a voltage stabilizing tube (D1) through a comparator (U1) to output high and low levels, the high and low levels are added to the reverse input end of a differential amplifier (U3) of a PWM controller (U2) through a diode (D2) and an optical coupler (U4), and the stable reference voltage is connected to the positive input end of the differential amplifier (U3). The circuit of the invention has the advantages of simple structure, high conversion efficiency by adopting a booster mode of superposing two groups of push-pull circuits compared with a common fly-back circuit, low parameter requirement for devices and lower production cost.

Description

technical field The invention relates to a DC boost circuit, in particular to a DC boost circuit suitable for micro-power inverter. Background technique Photovoltaic (PV) cells generate direct current, which is stored in the battery by the controller. The battery voltage will fluctuate around 12V with the change of power. Most household appliances require AC 220V power supply, and have high requirements on the amplitude and waveform quality of AC. Traditional inverter devices generally adopt the method of inverting first and then boosting voltage, which has high cost, complicated circuit, difficult debugging and poor waveform quality. The high-frequency inverter device is a device that converts the DC power of the battery into a stable 330V DC power through a DC boost, and then converts it into a 50HZ, 220V AC power through an inverter circuit. The circuit is relatively simple, the cost is low, the digital control method is adopted, the debugging is simple, and the wavefo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02M3/337

Inventor 魏学业袁磊

Owner BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com