Plane type heat exchanger

A heat exchanger, planar technology, applied in the field of planar heat exchangers, can solve the problems of cylindrical heat exchangers, such as large volume, difficulty in manufacturing, deformation of flat parts, etc., to achieve the effect of improving heat transfer efficiency and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The structure and operation of the preferred embodiment of the present invention will be specifically described below with reference to the accompanying drawings.

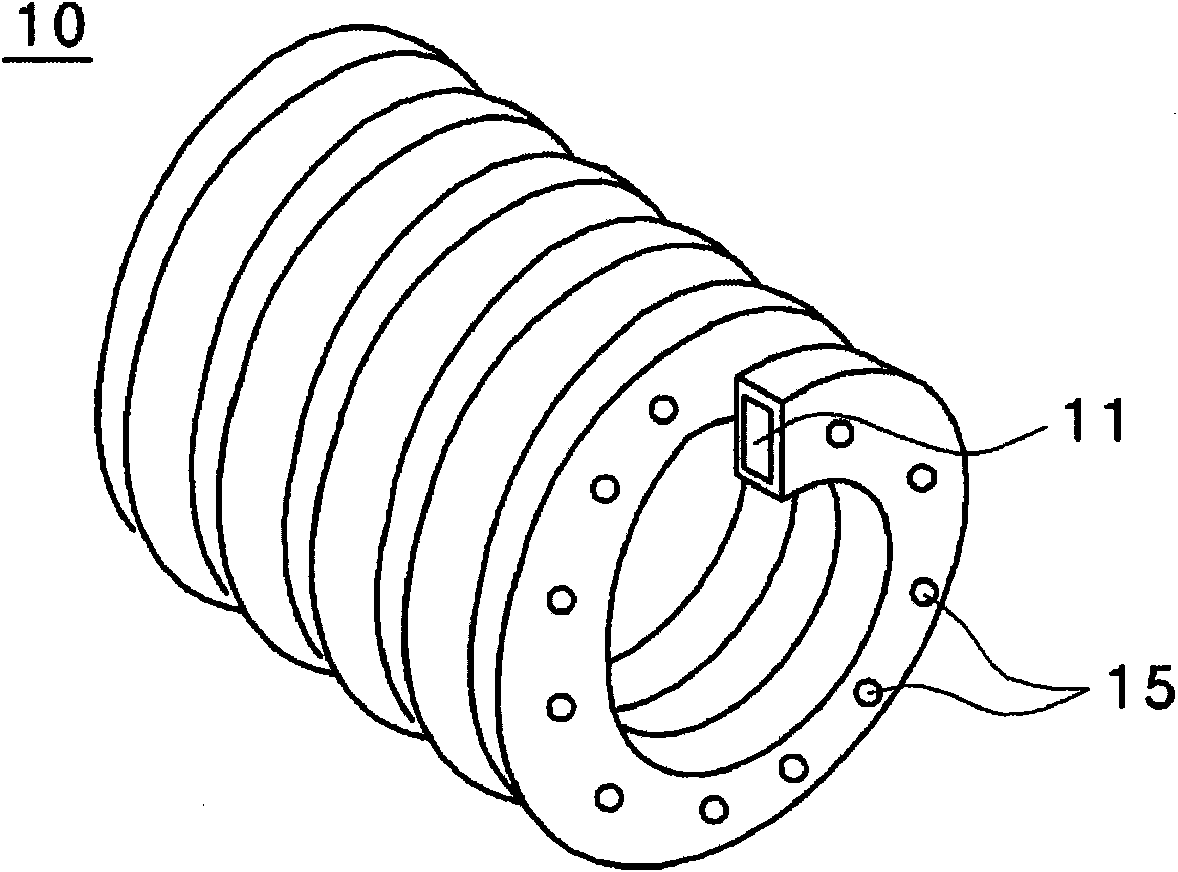

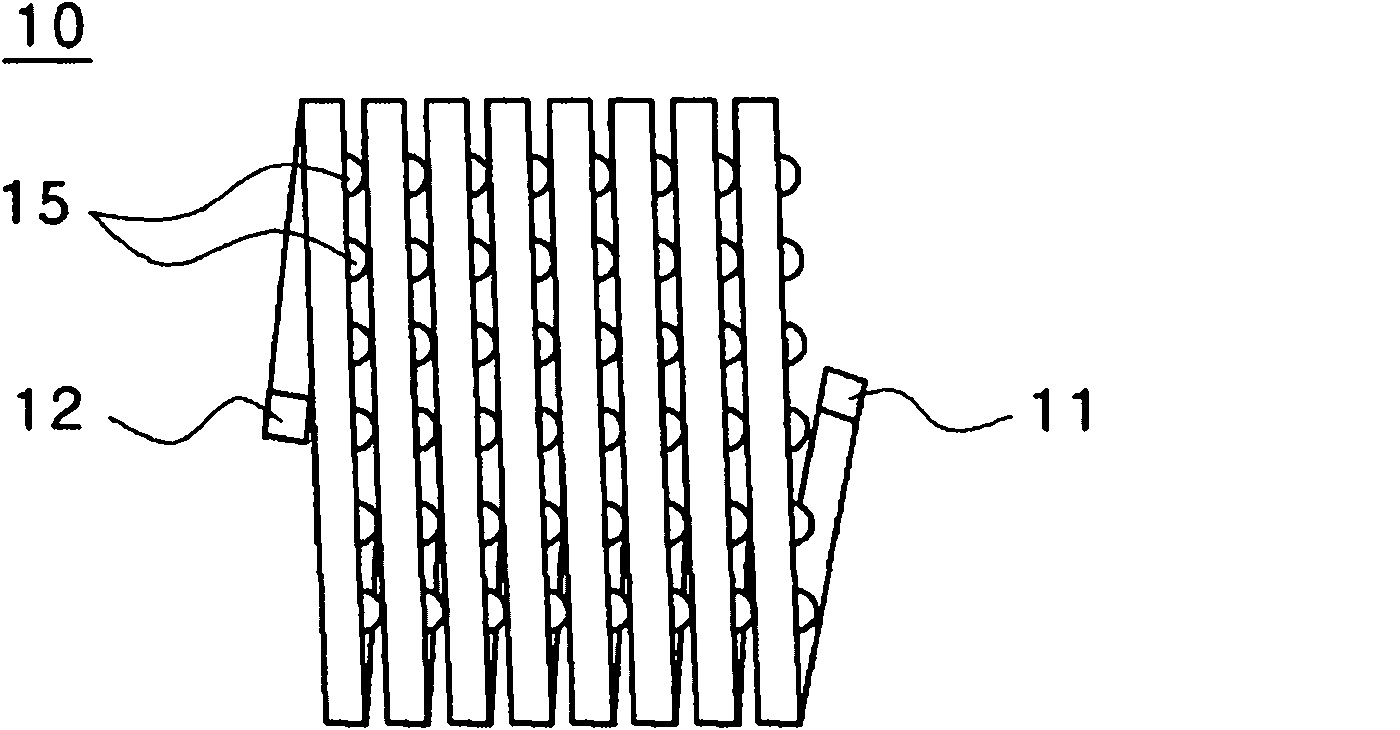

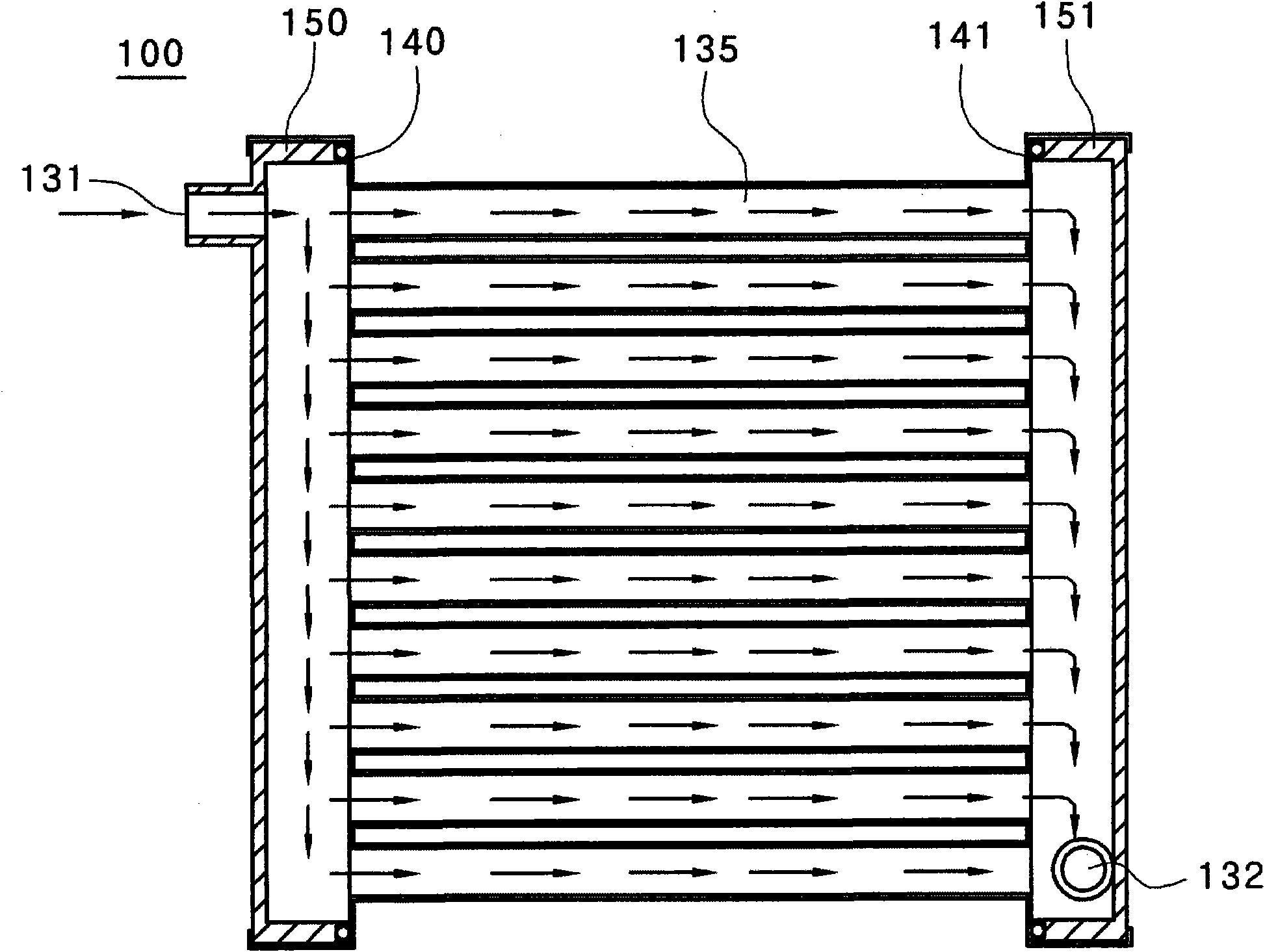

[0034] image 3 is a sectional view showing the structure of a planar heat exchanger of an embodiment of the present invention, Figure 4 yes image 3 exploded perspective view.

[0035] The heat exchanger 100 of the first embodiment of the present invention includes: a plurality of heat exchange tubes 135 arranged parallel to each other at uniform intervals; inner plates 140, 141, and the two ends of the heat exchange tubes 135 are respectively inserted and fixed in the inner plates 140, 141; 141 ; and outer panels 150 , 151 that cover the outer surfaces of the inner panels 140 , 141 and form spaces inside.

[0036] The heat exchange tube 135 is a planar structure with a rectangular section whose width is greater than its height on the side contacting the gas for laminar flow and is flat on the side cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com