Microemulsion oil-in-water insect aerosol

An oil-in-water, aerosol technology, used in biocides, biocides, animal repellents, etc., can solve problems such as uneven distribution of chemical components, affecting product use effects, and affecting product stability, etc. The liquid phase of the product is uniform and stable, the use is safe, and the production process is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

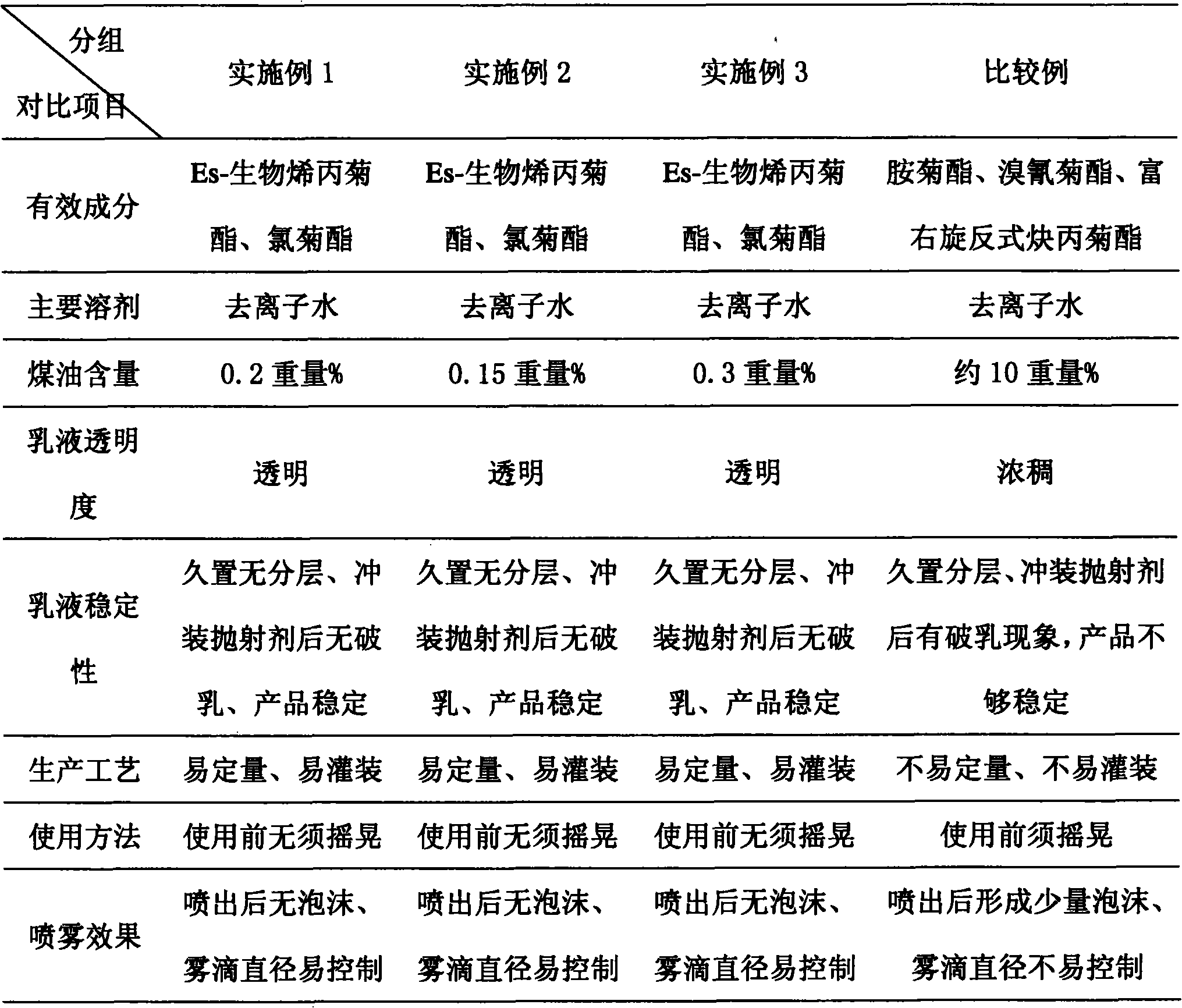

Examples

Embodiment 1

[0028] Weigh respectively 2.0g Es-bioallethrin (content ≥ 94%), 1.4g permethrin (content ≥ 90%), 1.0g kerosene, 2.0g butanobuterol, 21.0g nonylphenol polyoxyethylene ether Phosphate ester and 0.5g essence were added to the mixing bucket, and stirred for 5 minutes; then weighed 271.1g of deionized water, slowly added to the above mixing bucket under stirring, and continued to stir for 5 minutes after the addition; and weighed 1.0g of sodium benzoate Slowly add it into the above mixing tank under stirring, continue to stir for 5 minutes to obtain the liquid medicine; put the above prepared medicine liquid into a 600mL aerosol tank, then insert the valve, seal it, and fill it with dimethyl ether 200g, just install the spray cap.

Embodiment 2

[0030] Weigh respectively 1.25g Es-biological allethrin (content ≥ 94%), 1.75g permethrin (content ≥ 90%), 0.75g kerosene, 2.5g butanobuterol, 26.0g nonylphenol polyoxyethylene ether Phosphate ester and 0.25g of essence were added to the mixing tank, and stirred for 5 minutes; then weighed 250.0g of deionized water, slowly added to the above mixing tank under stirring, and continued to stir for 5 minutes after adding; and weighed 0.5g of sodium benzoate Slowly add it into the above mixing tank under stirring, continue to stir for 5 minutes to obtain the liquid medicine; put the above prepared medicine liquid into a 600mL aerosol tank, then insert the valve, seal it, and fill it with dimethyl ether 217g, just install the spray cap.

Embodiment 3

[0032] Weigh respectively 2.75g Es-biological allethrin (content ≥ 94%), 1.0g permethrin (content ≥ 90%), 1.5g kerosene, 1.5g butanobuterol, 17.5g nonylphenol polyoxyethylene ether Phosphate ester and 0.75g of essence were added to the mixing tank, and stirred for 5 minutes; then weighed 280.0g of deionized water, slowly added to the above mixing tank under stirring, and continued to stir for 5 minutes after adding; and weighed 1.5g of sodium benzoate Slowly add it into the above mixing tank under stirring, continue to stir for 5 minutes to obtain the liquid medicine; put the above prepared medicine liquid into a 600mL aerosol tank, then insert the valve, seal it, and fill it with dimethyl ether 193.5g, after installing the spray cap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com