Tea leave tray

A tray and tea technology, which is applied in the field of tea processing equipment, can solve the problems of heavy tea tray frame, time-consuming and labor-consuming, inconvenient cleaning, etc., and achieve the effects of improved production efficiency, excellent and stable quality, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

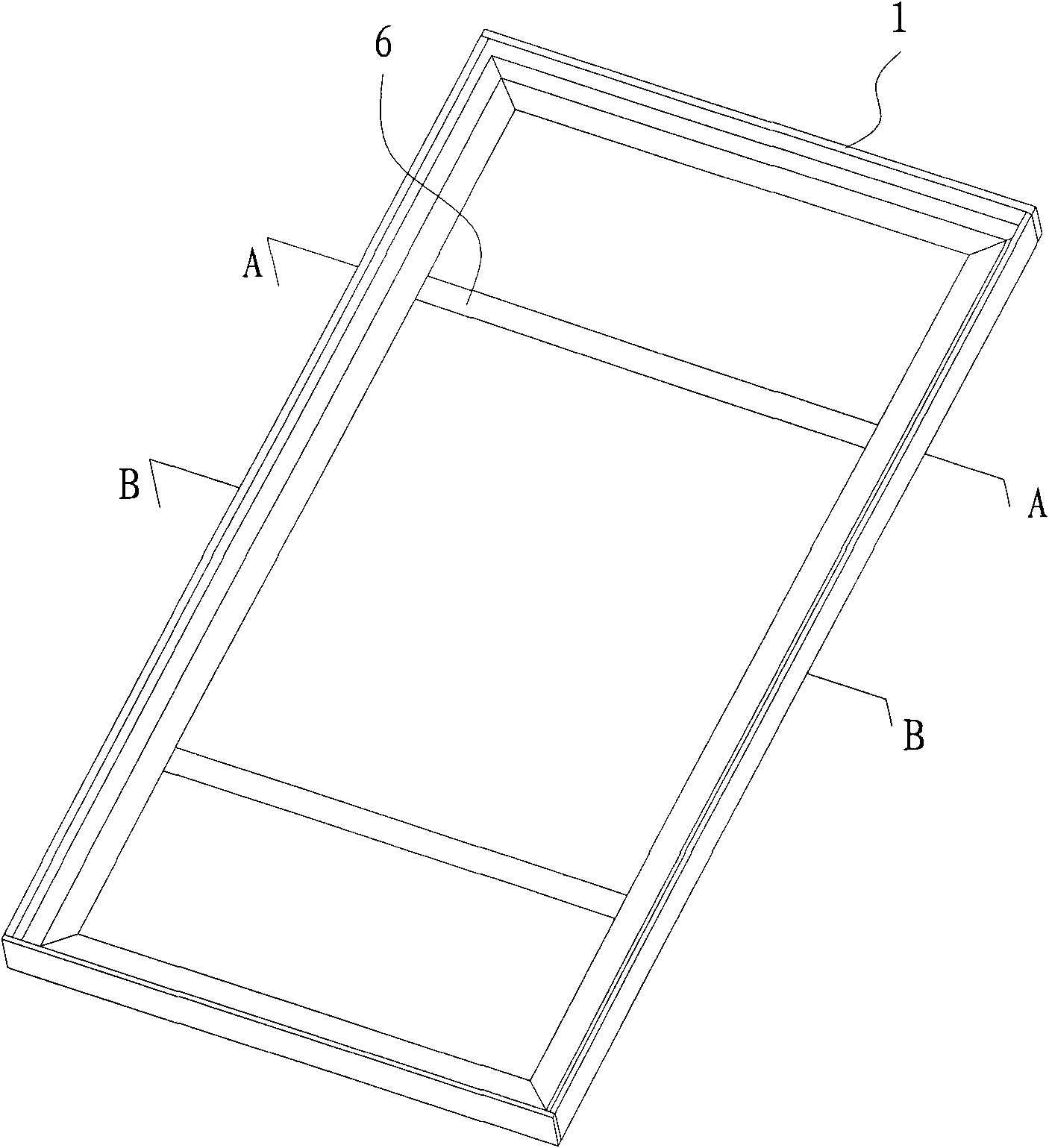

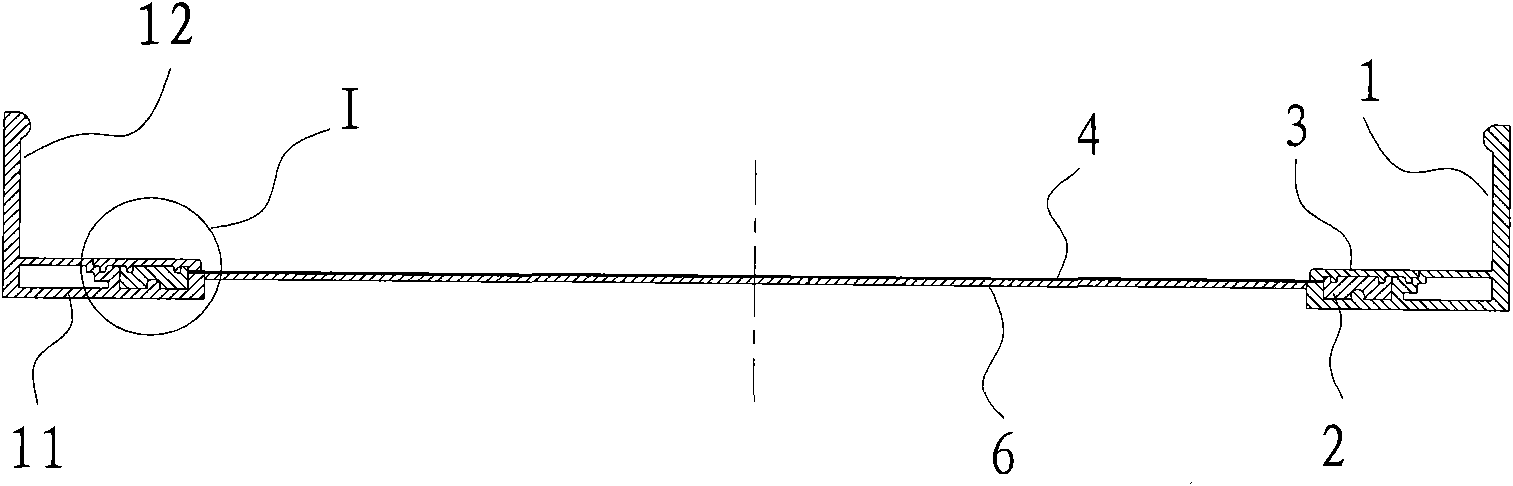

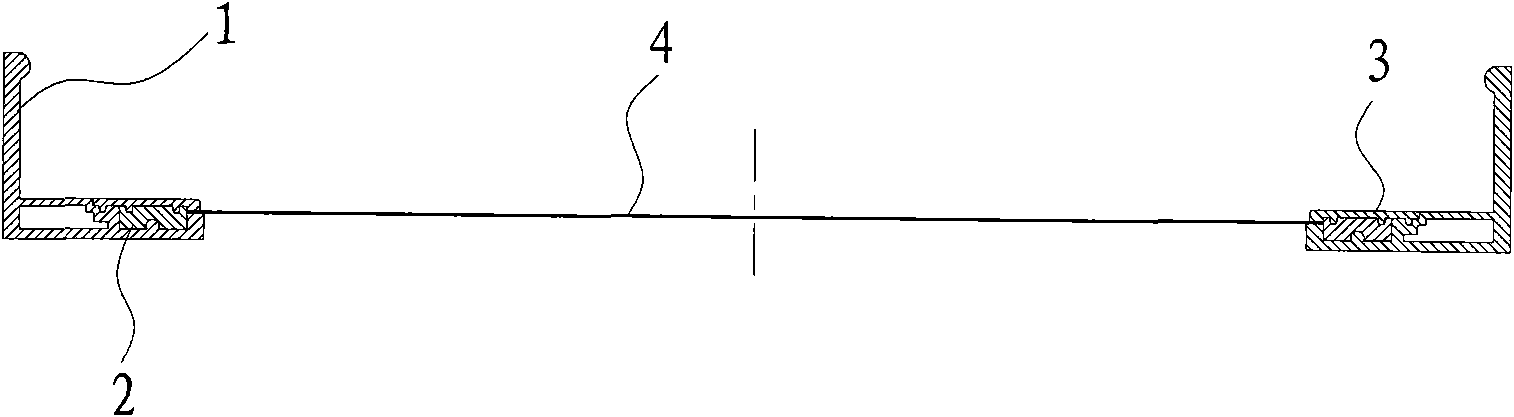

[0019] refer to Figure 1 to Figure 4 , Embodiment 1 discloses a tea tray, which includes an outer frame 1, a tension strip 2, a decorative plate 3 and a metal mesh 4, the outer frame 1 is connected end to end along the length direction to form a rectangular closed structure, the cross section of the outer frame 1 It has a horizontal portion 11 extending in the horizontal direction and a vertical portion 12 extending in the vertical direction. On the upper surface of the horizontal portion 11 of the outer frame 1, there is a sinking groove 111 extending in the longitudinal direction. Protrusion 112, the lower surface of the tension strip 2 is provided with a groove 21 suitable for the cylindrical protrusion 112, the groove 21 is a cylindrical groove with a wrapping angle of 200 degrees along the circumferential direction, rectangular The metal mesh 4 is set on the horizontal part 11 of the outer frame 1, the outer edge of the metal mesh 4 extends to the side wall of the sinker...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap