Preparation of asparagus ethanol extract and application thereof in cigarette

A technology for ethanol extraction and asparagus, which is applied in the application, tobacco, tobacco processing and other directions to achieve the effects of improving the quality of smoking food and improving the poor moisturizing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

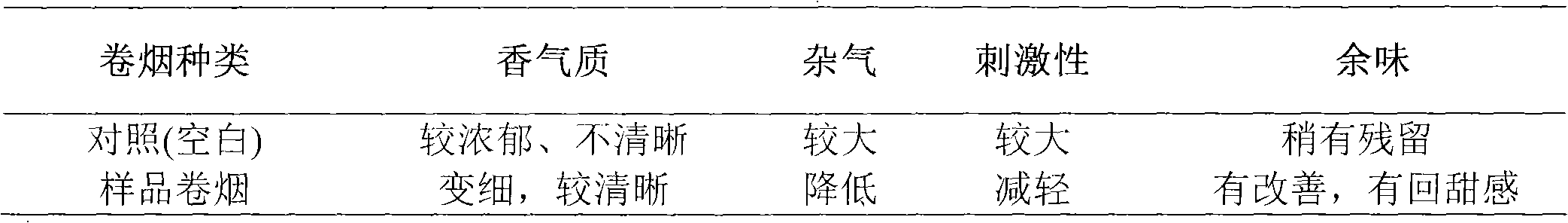

Embodiment 1

[0024] Asparagus after pre-treatments such as infrared enzyme inactivation, washing, impurity removal, and drying, bake in an oven at 50°C for 4 hours until the moisture content is below 10%, pass through a 40-mesh sieve after crushing, and add 4 times the weight of Reflux extraction with 95% ethanol at 90°C for 2 hours, the extract is cooled, filtered, concentrated to a dry matter concentration of 10%, and sprayed evenly on shredded tobacco in the cigarette feeding process at a ratio of 0.5% by weight of shredded tobacco, and made into cigarettes. The results of smoking evaluation show that after adding the ethanol extract of asparagus, the smoke has no peculiar smell, and the aroma is clearer than that of the blank cigarette, and the miscellaneous gas and irritation are all reduced.

Embodiment 2

[0026] Asparagus after pre-treatments such as infrared enzyme inactivation, washing, impurity removal, and drying, bake in an oven at 50°C for 4 hours until the moisture content is below 10%, pass through a 40-mesh sieve after crushing, and add 3 times the weight of Soak in 95% ethanol for 7 days at room temperature. After filtering, the soaking liquid is concentrated to a dry matter concentration of 10%. According to the ratio of 0.6% by weight of the shredded tobacco, it is evenly sprayed on the shredded tobacco of the cigarette in the cigarette feeding process, and made into a cigarette. The results of smoking evaluation showed that after adding the asparagus ethanol soaking liquid, the smoke had no peculiar smell, and the aroma was clearer than that of the blank cigarette, and the miscellaneous gas and irritation were all reduced.

Embodiment 3

[0028] Asparagus after pre-treatments such as infrared enzyme inactivation, washing, impurity removal, and drying, bake in an oven at 60°C for 3 hours until the moisture content is below 10%, pass through a 60-mesh sieve after crushing, and place in Soxhlet extraction Add 3 times the weight of 95% ethanol to heat and reflux at 85°C for 5 hours, the extract is cooled, filtered, concentrated to a dry matter concentration of 5%, and sprayed evenly on the shredded tobacco in the cigarette feeding process according to the proportion of 0.5% by weight of shredded tobacco on, and made into cigarettes. The results of smoking evaluation show that after adding the ethanol extract of asparagus, the smoke has no peculiar smell, and the aroma is clearer than that of the blank cigarette.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com