Aluminum-like rod surface scraping mechanism

A technology of aluminum rod and scraping device, which is applied in the field of devices for removing the oxide layer on the surface of metal rods, can solve the problems of fast wear of wire brushes, large mechanical noise, and large traction force, and achieve reliable basic quality assurance, reduce production costs, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

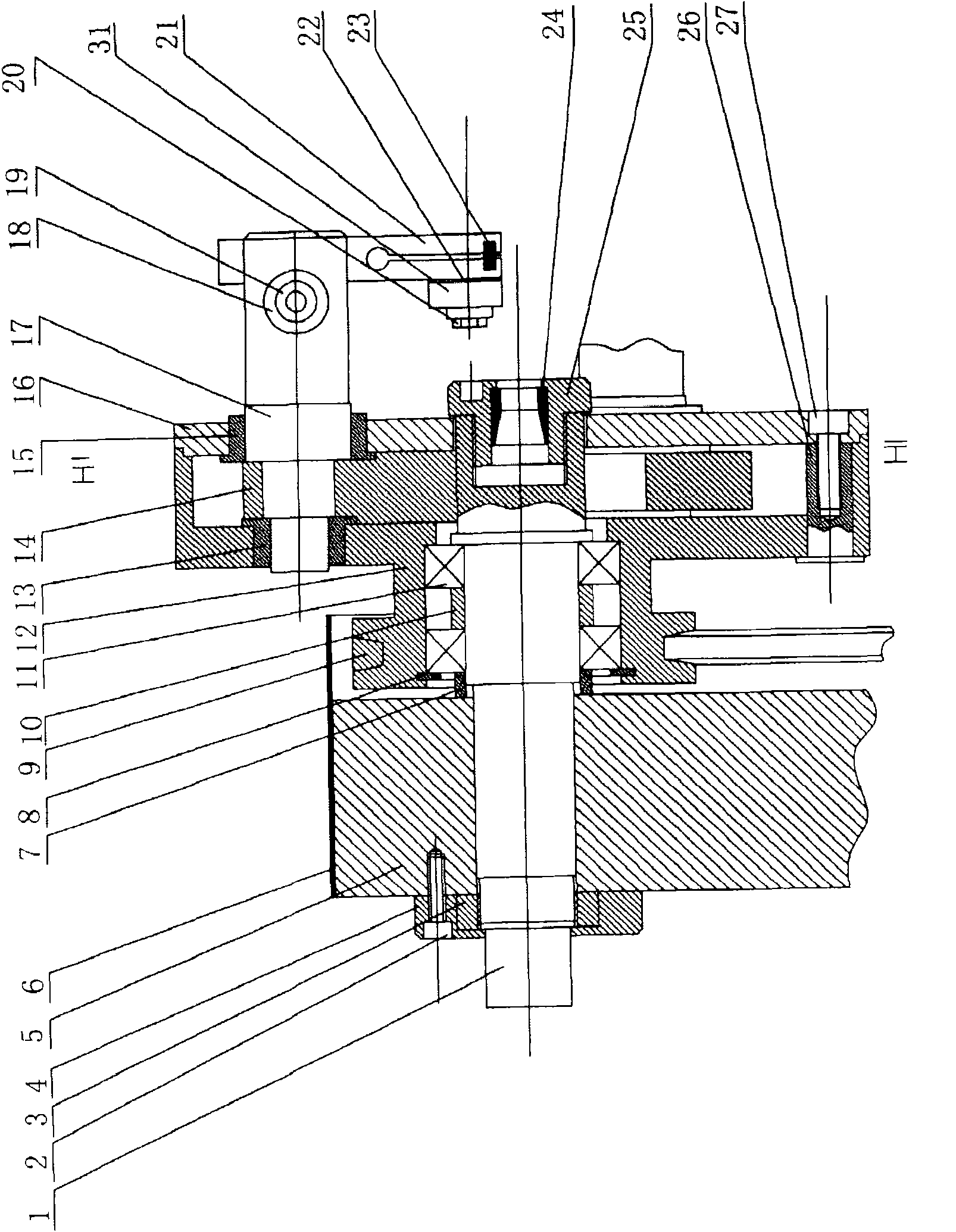

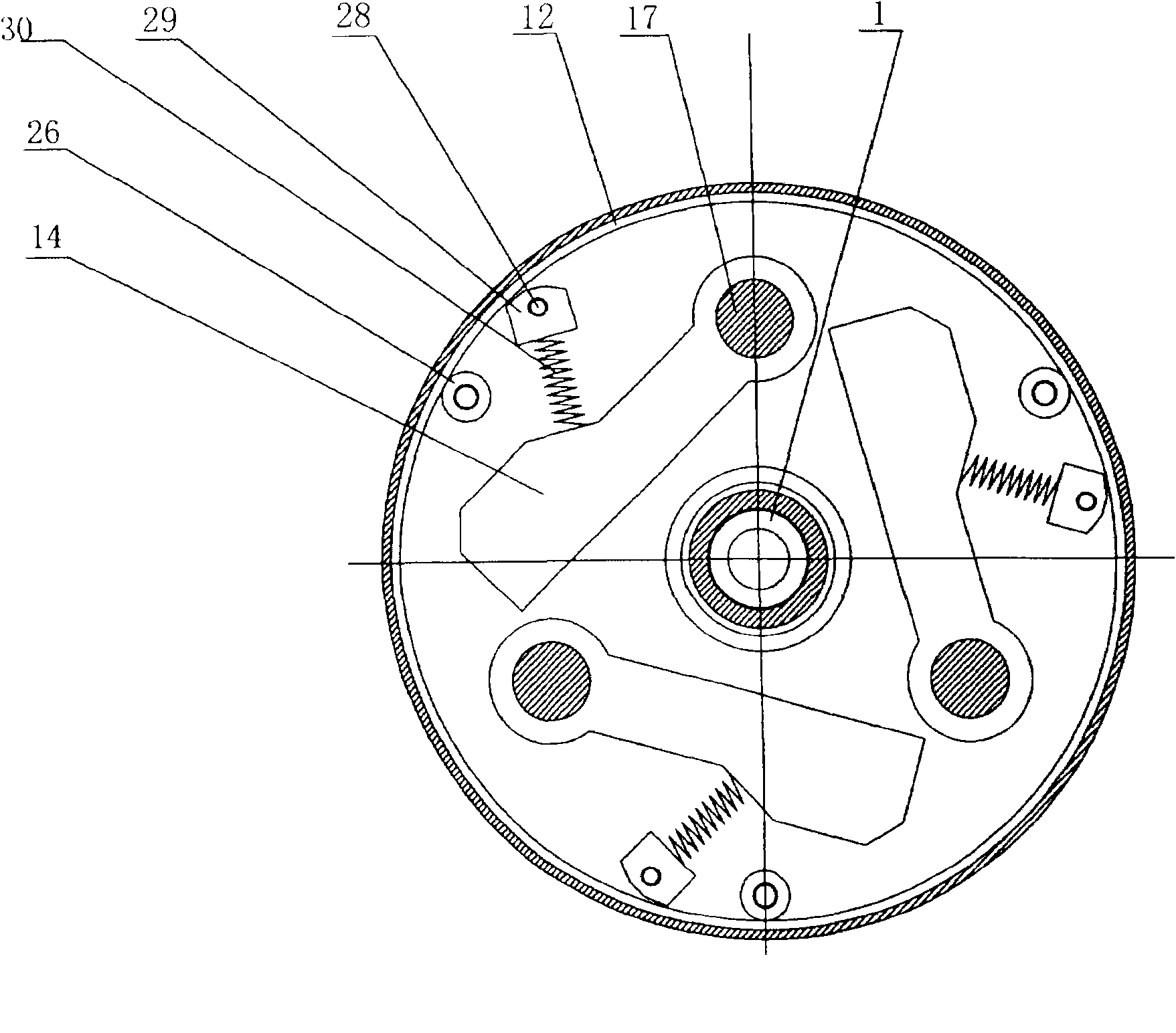

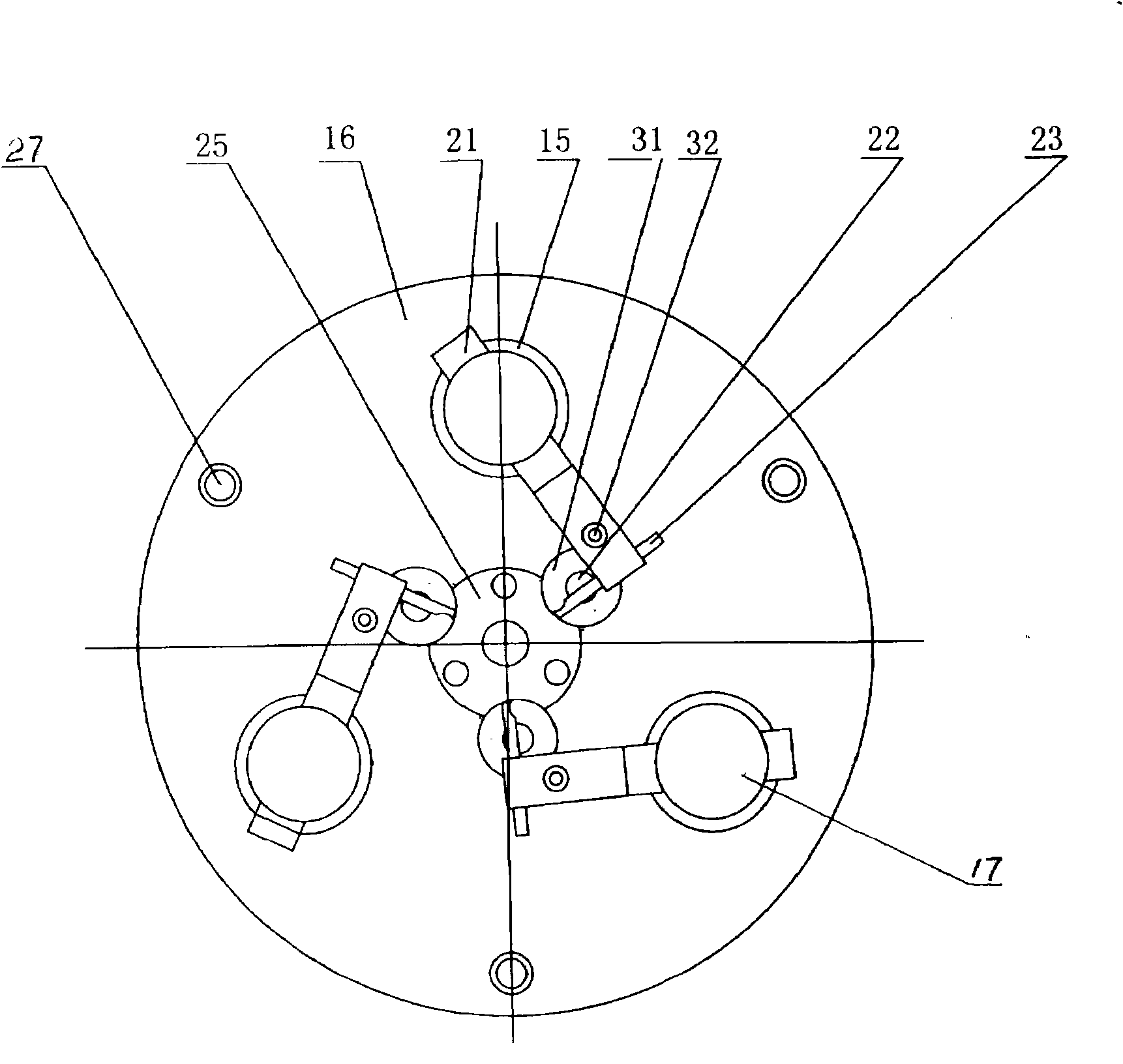

[0013] refer to Figure 1 to Figure 3 , the surface scraping mechanism of the imitation aluminum rod of the present invention, the base is provided with a cover plate 6, the base 5 is provided with a main shaft 1 for positioning the aluminum rod, the main shaft 1 is axially locked on the base 5, and one end of the main shaft 1 is connected to A nut 3 is pressed tightly through a flange 4, and the flange 4 is connected with the base 5 through a hexagon socket head cap screw 2, so that the left end of the main shaft is axially locked. The main shaft 1 is provided with a positioning hole for the aluminum rod to pass through. In the positioning hole at the other end of the main shaft 1, a mandrel sleeve 25 is threaded. The mandrel sleeve 25 is provided with a core sleeve 24. The core sleeve 24 can increase the positioning accuracy of the aluminum rod. Two bearings 11 are fixed on the shaft section of the main shaft 1, and the two bearings are separated and limited by a spacer 10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com