Web feed printing finishing production equipment

A production equipment and reel technology, applied in printing, printing machines, transfer printing, etc., can solve the problems of unguaranteed printing surface decoration quality, increased size error of printing surface finishing, and no dust removal equipment, etc., to achieve The effect of metal decoration is good, the production quality is good, and the production efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

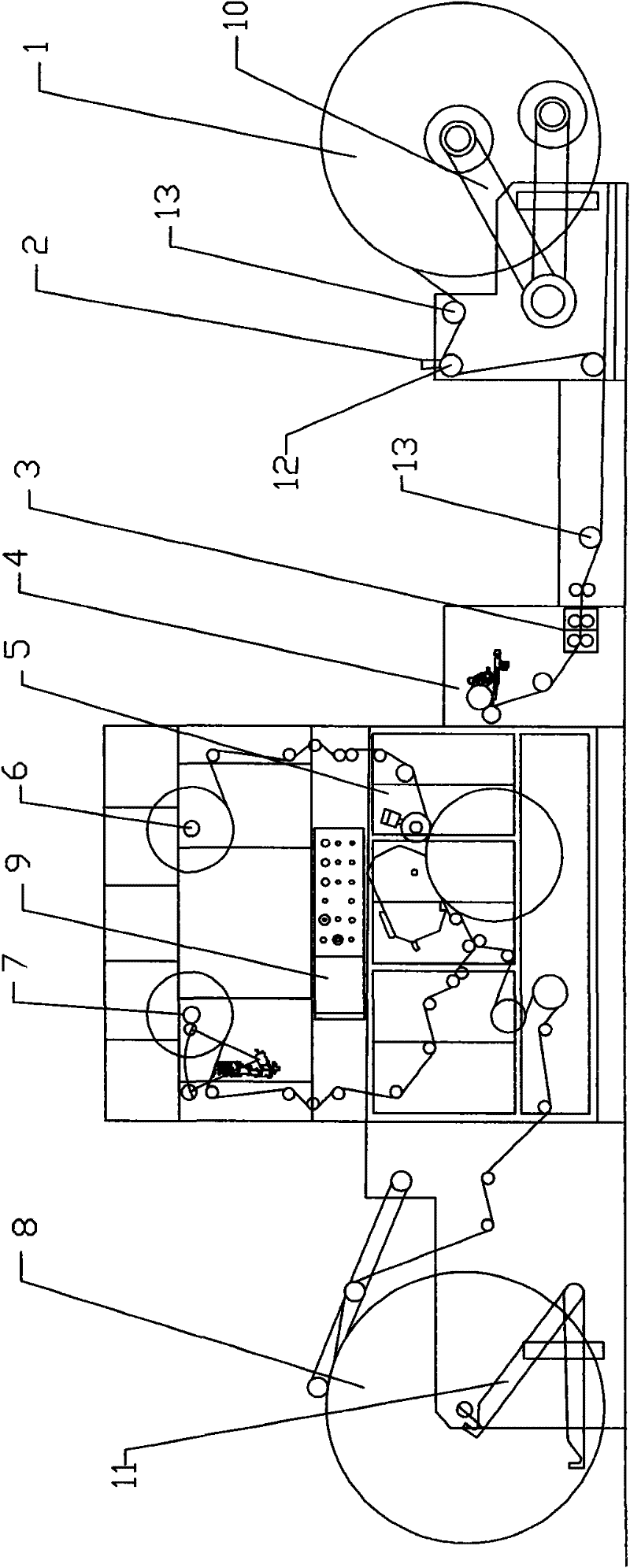

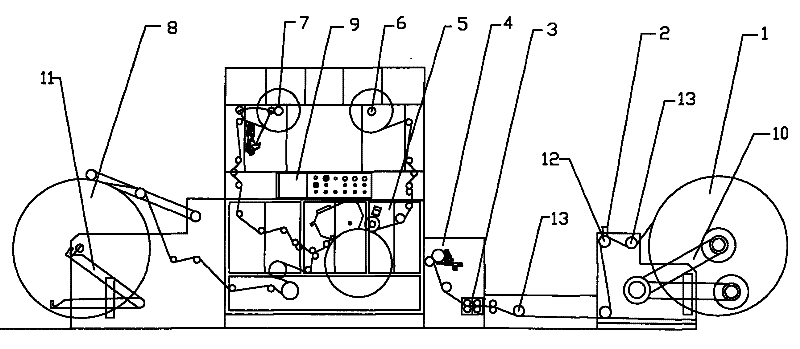

[0013] Below in conjunction with accompanying drawing, the present invention will be further described, figure 1 Among them, the roll printing and finishing production equipment includes a box body, a UV coating device 4, an embossing transfer device 5, a film unwinding device 6, a film winding device 7, and a control system 9, and is characterized in that: the The production equipment is provided with a paper unwinding device 1, a deviation correcting device 2, a dust removal device 3, and a paper rewinding device 8. The paper unwinding device 1 and the paper rewinding device 8 are respectively installed on the At the front and back ends of the production equipment, the paper unwinding device 1 passes through the transmission shafts 12 and 13 and then passes through the deviation correction device 2, the dust removal device 3, the UV coating device 4, the embossing transfer device 5 and the paper winding device 8 in turn. Connection; the deviation correction device 2 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com