Method for preparing titanium dioxide hydrolysis crystal seed

A technology of seed crystal and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve equipment requirements. Low seed rutile is used to prepare titanium dioxide plus hydrolyzed crystal seed, which affects the dispersion of seed crystals and affects the quality of seed crystals, etc. problem, to achieve the effect of low equipment requirements, stable seed crystal activity and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of titanium dioxide plus hydrolyzed seed crystals by the method of the present invention

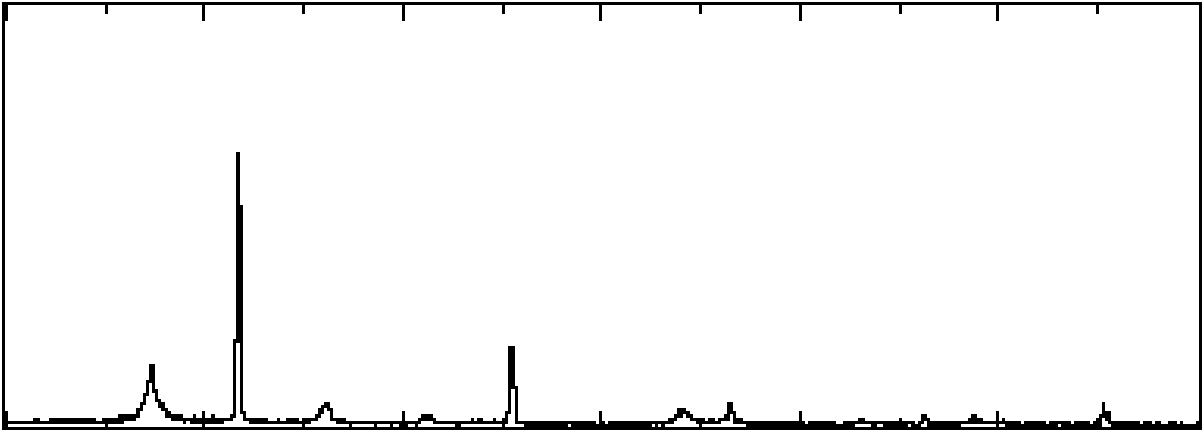

[0027] In the NaOH solution of 90mL 2wt%, add concentration and be 450g / L (as TiO 2 count) TiCl 4 Aqueous solution, neutralized to pH 0.5, while keeping the system temperature not exceeding 40°C. After fully stirring, the temperature was raised to 60°C at a heating rate of 0.5°C / min, and kept for 20 minutes of aging, and the system was cooled to room temperature to obtain titanium dioxide plus hydrolysis seeds, and the TiO2 was analyzed chemically. 2 The content is 30g / L. Through X-ray diffraction (XRD) analysis, the rutile content of gained seed crystal is greater than 99%, and XRD diffractogram sees figure 1 . After standing for 25 days, it can still be used as a hydrolysis seed.

Embodiment 2

[0028] Example 2 Using the method of the present invention to prepare titanium dioxide plus hydrolyzed seed crystals

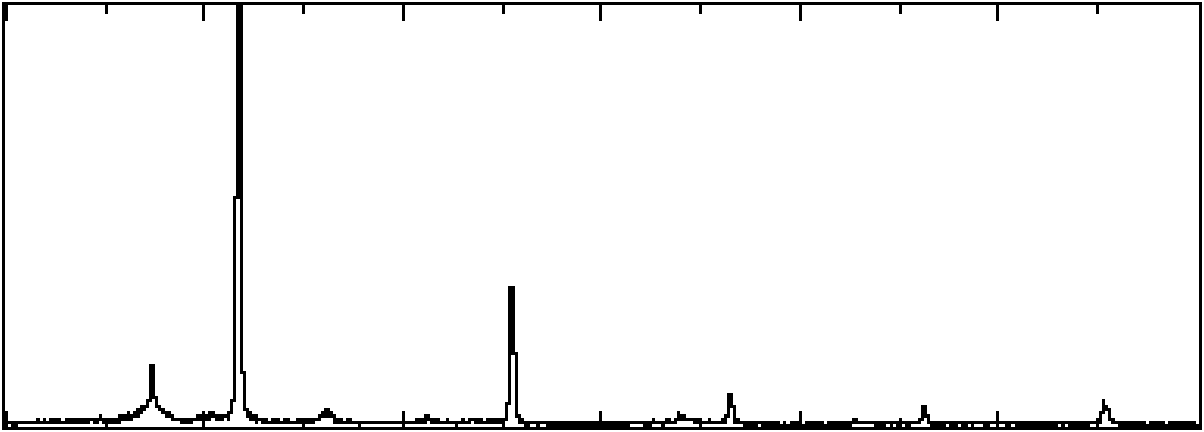

[0029] In the NaOH solution of 90mL 5wt%, add concentration and be 250g / L (as TiO 2 count) TiCl 4 Aqueous solution, neutralized to pH 0, while keeping the system temperature not exceeding 40°C. After fully stirring, the temperature was raised to 75°C at a heating rate of 3°C / min, and kept for 40 minutes of aging, and the system was cooled to room temperature to obtain titanium dioxide plus hydrolyzed seed crystals, and the TiO2 was analyzed chemically. 2 The content is 35g / L. Through X-ray diffraction (XRD) analysis, the rutile content of gained seed crystal is greater than 99%, and XRD diffractogram sees figure 2 . After standing for 25 days, it can still be used as a hydrolysis seed.

Embodiment 3

[0030] Example 3 Using the method of the present invention to prepare titanium dioxide plus hydrolyzed seed crystals

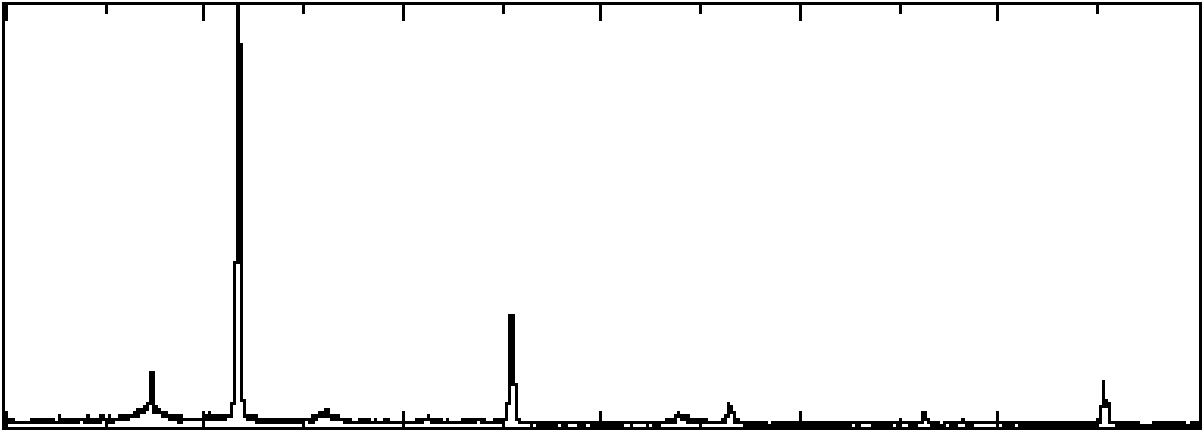

[0031] To 90mL of 15wt% KOH solution, add a concentration of 200g / L (as TiO 2 count) TiCl 4 Aqueous solution, neutralized to pH 2, while keeping the system temperature not exceeding 40°C. After fully stirring, the temperature was raised to 75°C at a heating rate of 3°C / min, and kept for 90 minutes of aging, and the system was cooled to room temperature to obtain titanium dioxide plus hydrolysis seeds, and the TiO2 was analyzed chemically. 2The content is 45g / L. Through X-ray diffraction (XRD) analysis, the rutile content of gained seed crystal is greater than 99%, and XRD diffractogram sees image 3 . It can still be used as a hydrolysis seed after 20 days of storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com