Drinking water source advanced water treatment method based on resin and zeolite

A deep purification and treatment method technology, applied in the direction of water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of saving treatment cost, reducing treatment time and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

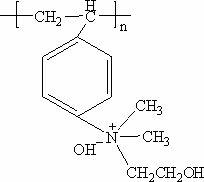

Method used

Image

Examples

Embodiment 1

[0029] Influent COD of a source water Mn 6mg / L, ammonia nitrogen content is 2.0mg / L, with 20m 3 / h flow rate into 10m 3 Stirred reactor, while adding 0.1m 3 The magnetic styrene-based strong base anion exchange resin (the magnetic styrene-based strong base anion exchange resin identified in the patent application 200910264445.X submitted by Nanjing University on December 22, 2009) and 0.1m 3 natural zeolite (40 mesh) in fresh resin tank with 0.1m 3 Pump the mixture of resin zeolite and water at a flow rate of / h, and stir well in the reactor. The resin zeolite and the reacted effluent mixture enter the inclined plate sedimentation tank to realize the separation of resin zeolite and water, and the resin zeolite precipitated at the bottom is separated by 0.1m 3 The flow rate per hour enters the buffer tank, of which 80% (weight percentage) is pumped into the reactor for reuse, 20% (weight percentage) enters the regeneration tank, and is regenerated with a 12% weight percenta...

Embodiment 2

[0034] Influent COD of a source water Mn 10mg / L, ammonia nitrogen content is 3.0mg / L, with 20m 3 / h flow rate into 20m 3 Stirred reactor, while adding 0.2m 3 The magnetic acrylic strong base anion exchange resin (the magnetic acrylic strong base anion exchange resin identified in the patent application 201010017687.1 submitted by Nanjing University on January 12, 2010) and 0.4m 3 artificial zeolite (20-40 mesh) in fresh resin tank with 0.2m 3 Pump the mixture of resin zeolite and water at a flow rate of / h, and stir well in the reactor. The resin zeolite and the reacted effluent mixture enter the inclined plate sedimentation tank to realize the separation of resin zeolite and water, and the resin zeolite precipitated at the bottom is separated by 0.2m 3 The flow rate of / h enters the buffer tank, 90% (weight percentage) of which is pumped into the reactor for reuse, 10% (weight percentage) enters the regeneration tank, and is regenerated with a 15% weight percentage NaCl sol...

Embodiment 3

[0039] Influent COD of a source water Mn 15mg / L, ammonia nitrogen content is 5.0mg / L, with 20m 3 / h flow rate into 20m 3 Stirred reactor, while adding 0.5m 3 Magnetic acrylic strong base anion exchange resin (the magnetic acrylic strong base anion exchange resin identified in the patent application 201010017687.1 submitted by Nanjing University on January 12, 2010) and 1m 3 artificial zeolite (20-40 mesh) in fresh resin tank with 0.1m 3 Pump the mixture of resin zeolite and water at a flow rate of / h, and stir well in the reactor. The resin and the reacted effluent mixture enter the inclined plate sedimentation tank to realize the separation of resin zeolite and water, and the resin zeolite precipitated at the bottom is separated by 0.2m 3 The flow rate per hour enters the buffer tank, 90% of which is pumped into the reactor for reuse, 10% enters the regeneration tank, and is regenerated with a 20% NaCl solution by weight, and the regenerated resin zeolite enters a fresh r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com