Asymmetric induction catalytic synthesis method for L-muscone

A technique of inducing catalysis and synthesis methods, applied in asymmetric synthesis, organic chemistry methods, chemical instruments and methods, etc., can solve problems that have not been reported in the literature, and achieve high optical purity, mild reaction conditions, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1): Synthesis of N-(3-methyl-cyclopentadecenyl)benzylamine

[0043] A water separator was installed in the three-necked flask. Condenser. dryer. After the thermometer is installed, add: benzene, MUSCONE, and amine in turn. The ratio of the material is: 100ml.5.2g (0.02mol). 2.5g (0.02mol). ) p-toluenesulfonic acid, continue to heat up to the reflux temperature to remove the moisture in the reaction to: 0.5-5ppm. use Na 2 CO 3 10%. Washing with aqueous solution, washing with water until neutral; anhydrous MgSO 3 Dry and evaporate the solvent under reduced pressure to obtain the crude product and purify it by column chromatography;

[0044] The product is:

[0045] Slightly yellow to yellow oily liquid 4.5g, yield 71.40%.

[0046] vmax(film)1644 -1 (C=N)

[0047] HNMR:

[0048] (CDCl 3 ): δ0.933~0.973 (3HlJ 66 h 3 CH 3 ): 1.231~1.44226H (d CH2-: 4.47 (2H brsCH 2 N): 7.13 (5H mph)

[0049] MF: C 23 h 37 Nmw: 327

[0050] N-(3-Methyl-cyclopentadecenyl)b...

Embodiment 2

[0071] 1): Synthesis of N-(3-methyl-cyclopentadecenyl)benzylamine

[0072] Put benzene, MUSCONE and amine into the container in turn, the ratio of the three materials is 5L:1mol:1mol; after stirring for 10min at 17~25°C, add p-toluenesulfonic acid after heating up to 60°C, p-toluenesulfonic acid and The mol ratio of MUSCONE is 1: 0.08; Continue to heat up to reflux temperature, remove the moisture in the reaction to: 0.5-5ppm; Use Na 2 CO 3 10%. Aqueous solution washing, water washing neutral; anhydrous MgSO 3 Dry and evaporate the solvent under reduced pressure to obtain the crude product and purify it by column chromatography to obtain N-(3-methyl-cyclopentadecenyl)benzylamine;

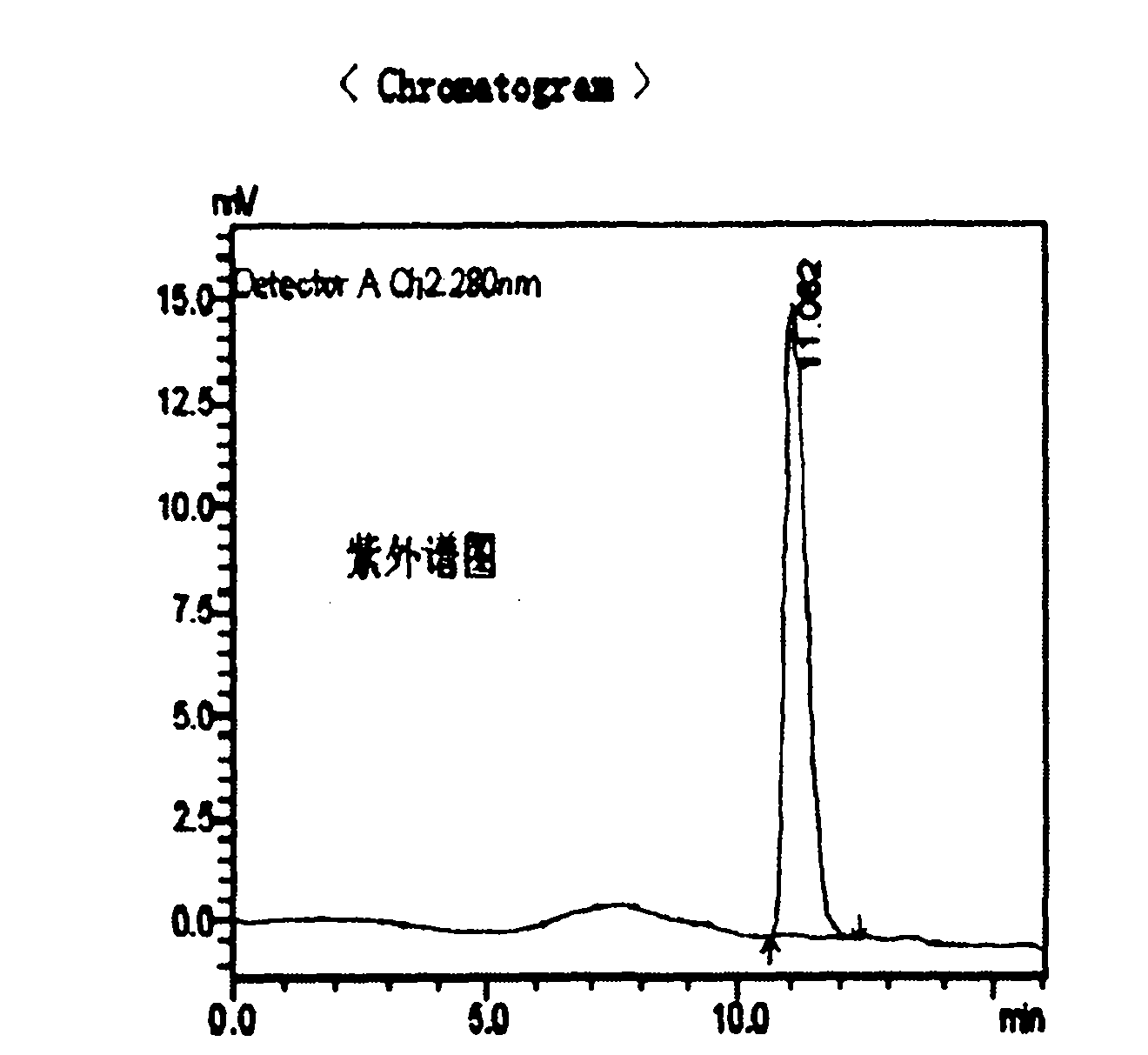

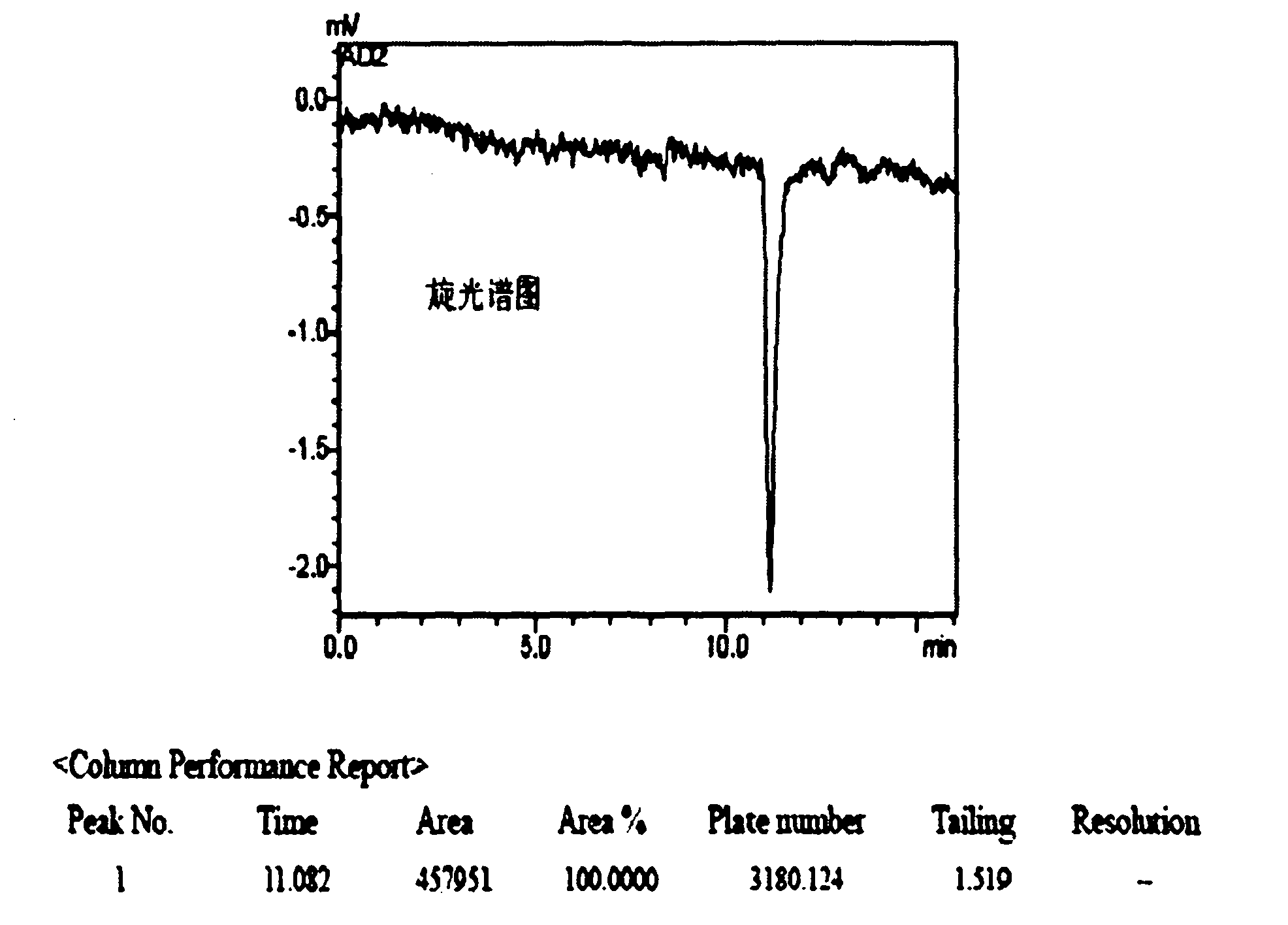

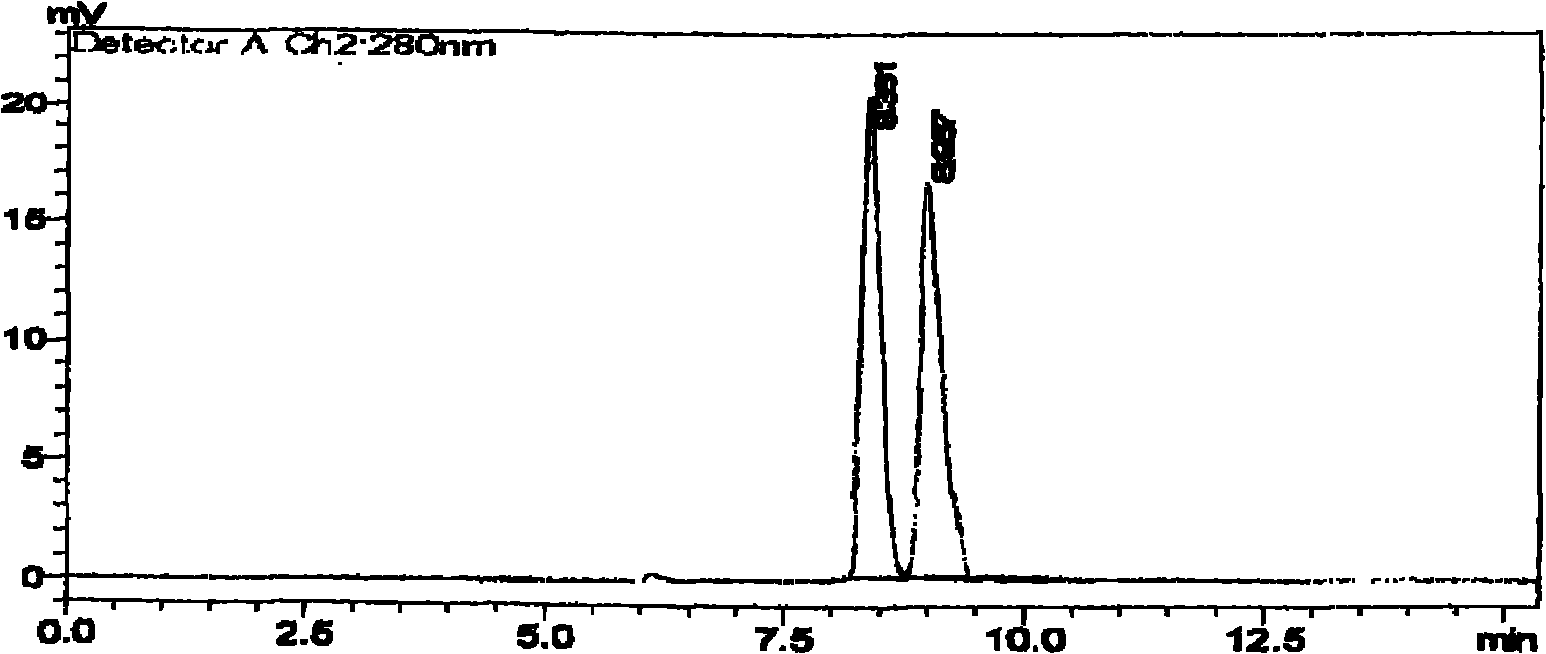

[0073] 2): Synthesis of L-MUSCONE

[0074] Described second step reaction is specifically: reactor uses N 2 After replacement, add C in sequence 2 h 5 OH, N-(3-methyl-cyclopentadecenyl)benzylamine, CH 2 Cl 2 and [RuC 12 .[(R)-BINAP] 2 ET 3 Access to H 2 The material ratio is 28L: 1.2mol:...

Embodiment 3

[0076] 1): Synthesis of N-(3-methyl-cyclopentadecenyl)benzylamine

[0077] Put benzene, MUSCONE and amine into the container in turn, the ratio of the three materials is 5L:1mol:1mol; after stirring for 10min at 17~25°C, add p-toluenesulfonic acid after heating up to 60°C, p-toluenesulfonic acid and The mol ratio of MUSCONE is 1: 0.08; Continue to heat up to reflux temperature, remove the moisture in the reaction to: 0.5-5ppm; Use Na 2 CO 3 10wt%.CH 2 Cl 2 Concentrate, wash and extract to neutral; anhydrous MgSO 3 Dry and evaporate the solvent under reduced pressure to obtain the crude product and purify it by column chromatography to obtain N-(3-methyl-cyclopentadecenyl)benzylamine;

[0078] 2): Synthesis of L-MUSCONE

[0079] Described second step reaction is specifically: reactor uses N 2 After replacement, add C in sequence 2 h 5 OH, N-(3-methyl-cyclopentadecenyl)benzylamine, CH 2 Cl 2 and [RuC 12 .[(R)-BINAP] 2 ET 3 Access to H 2; The material ratio is 32L: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com